Material Inorganic mineral powder (stone powder/colored sand) + environmentally friendly resin/mesh cloth (optional) + surface coating (UV/antique/wood grain transfer)

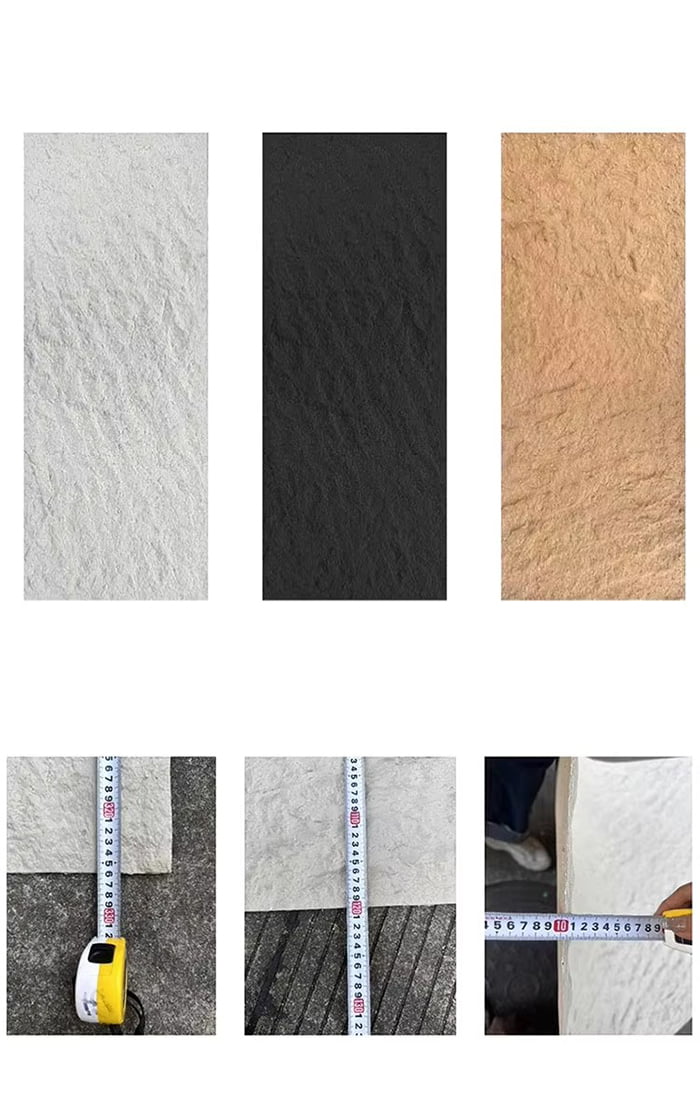

Size

Standard specifications: 1200mm×600mm, 1200mm×2400mm, 1200mm×3000mm (customization is available)

thickness 3mm-15mm (conventional thickness: 5mm, 8mm)

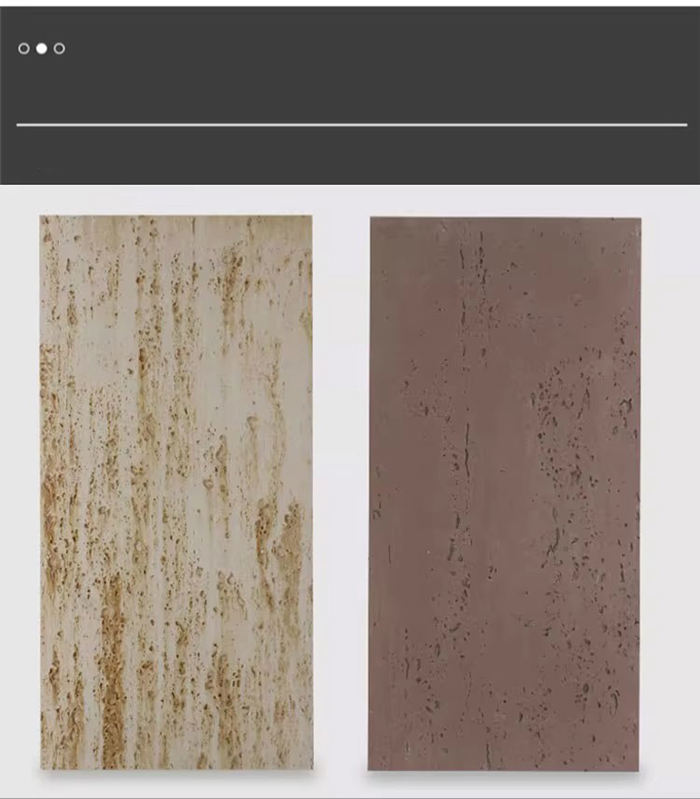

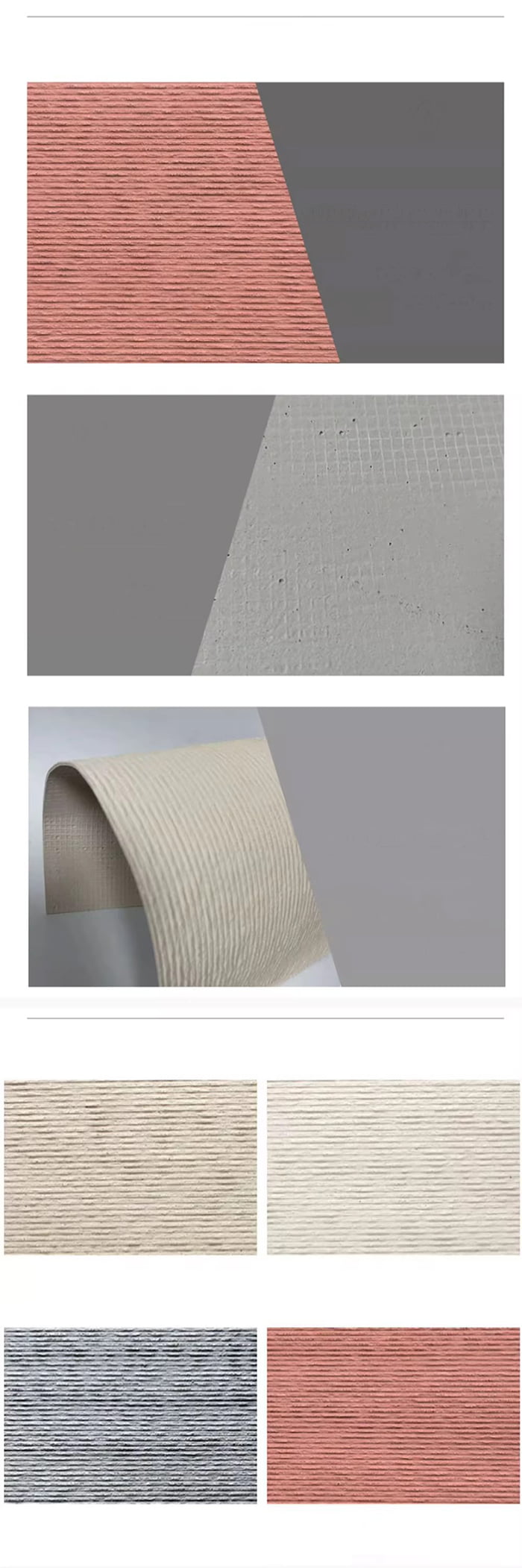

Surface treatment Grain surface, Travertine, Wood grain, Stone grain, Brushed metal, Antique surface, Solid color (matte/bright)color

Porcelain white, beige, light gray, dark gray, black, tan, etc. (support Pantone color customization)

Bending strength ≥30MPa (GB/T 1043.1 standard)

Moisture resistance Water absorption ≤0.5% (GB/T 17657 standard, 24-hour water immersion test)

Fire rating A1 non-flammable (GB 8624 standard) or B1 flame retardant (some models)

Formaldehyde emission ≤0.02mg/m³ (EN 717-1 standard, ENF environmental protection level)density 0.6-1.2g/cm³ (lightweight structure)

Weight About 3.0kg/m² (taking 8mm thickness as an example, which is 1/5 of stone)

Temperature resistance -50℃ to 100℃ (no cracking in long-term use)

Sound insulation performance

Weighted sound insulation ≥ 30dB (GB/T 19889 standard)

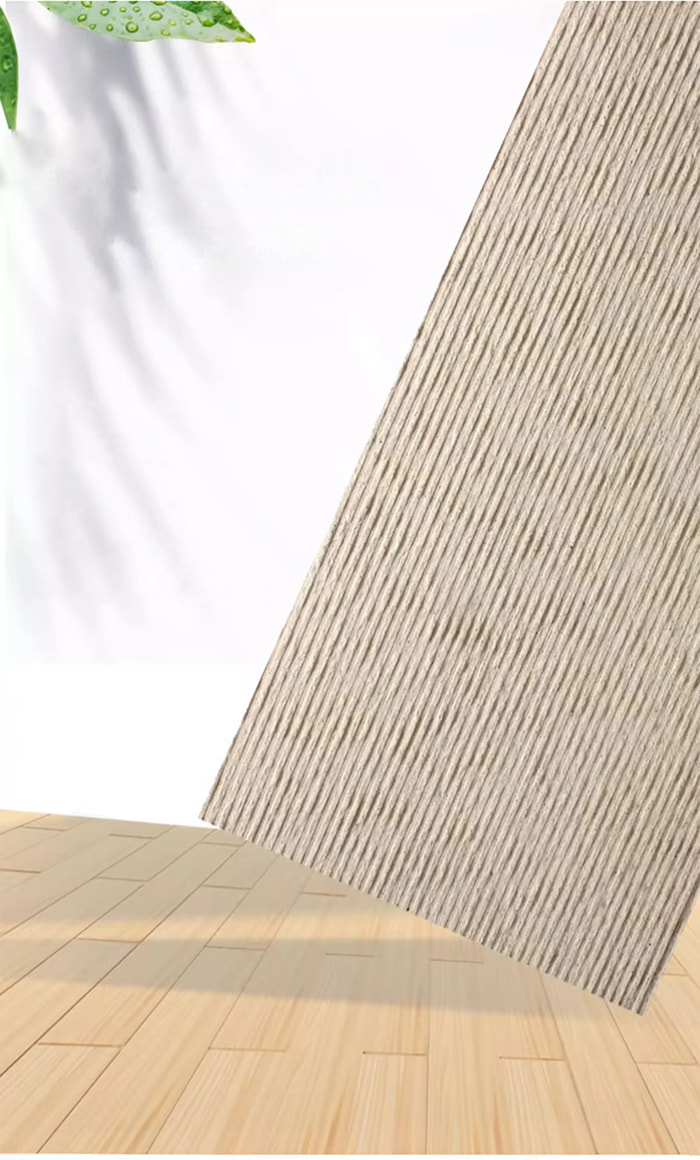

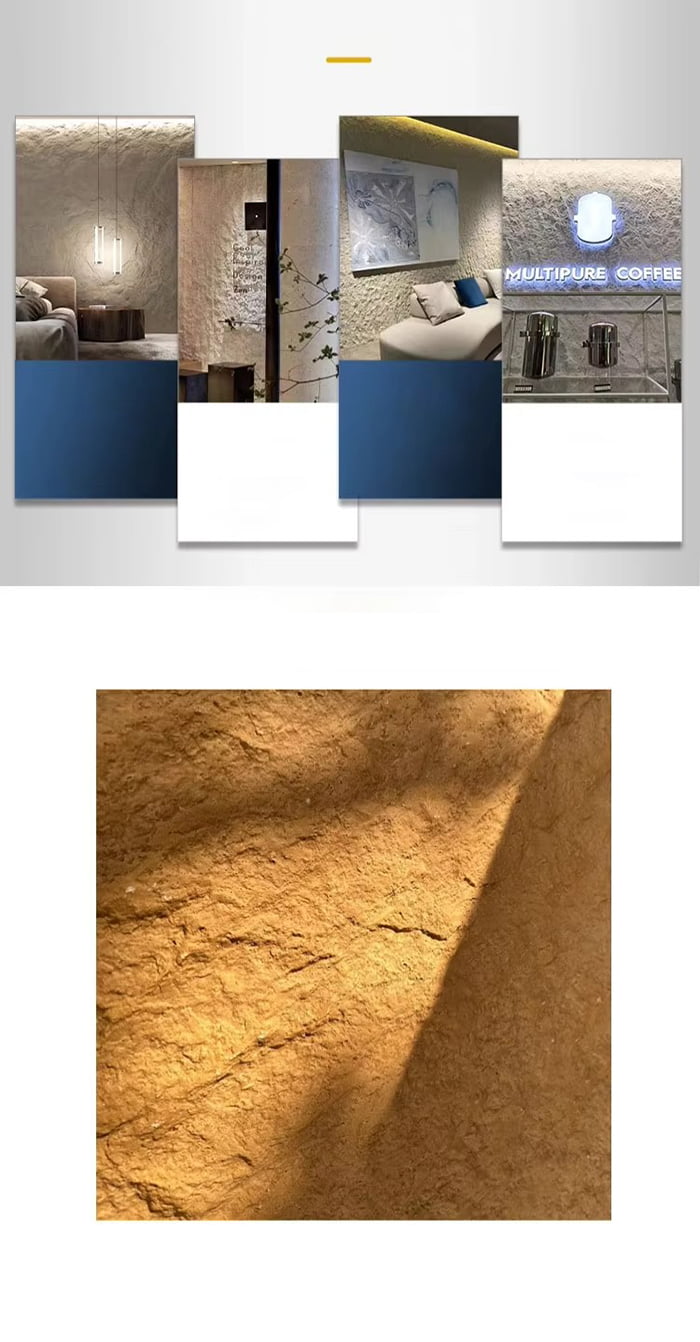

Soft stone wall panels are made of inorganic mineral powder (such as stone powder, colored sand) as the core raw material, and are made of environmentally friendly resin or mesh cloth reinforcement materials, through compression molding and surface coating. Its core features include ultra-thin bendability, high imitation stone texture, environmental protection and non-toxicity, and excellent fire and moisture resistance. It is suitable for indoor and outdoor wall decoration, especially for complex curved surface design.

Architectural Decoration

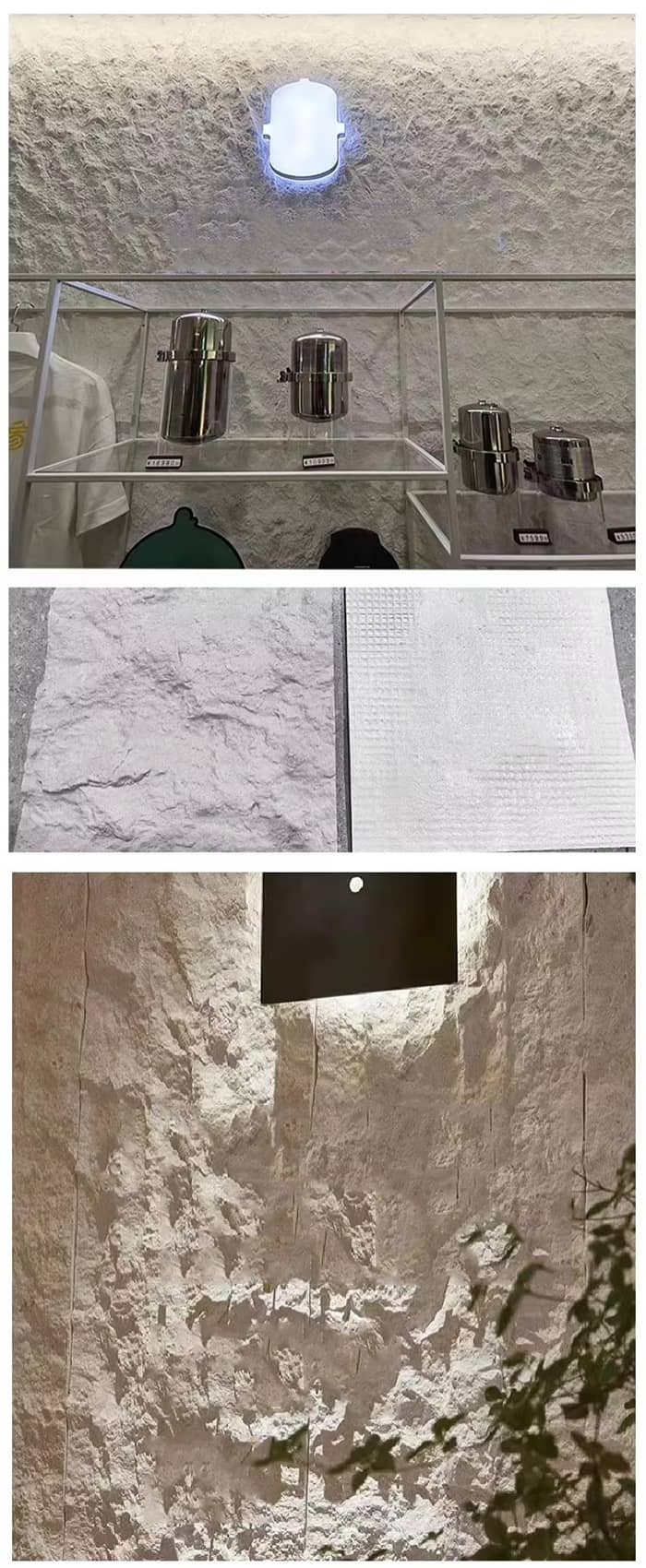

Internal and external walls : Imitation stone and imitation wood grain effects enhance the texture of the space and are suitable for hotels, shopping malls, hospitals, schools, etc.

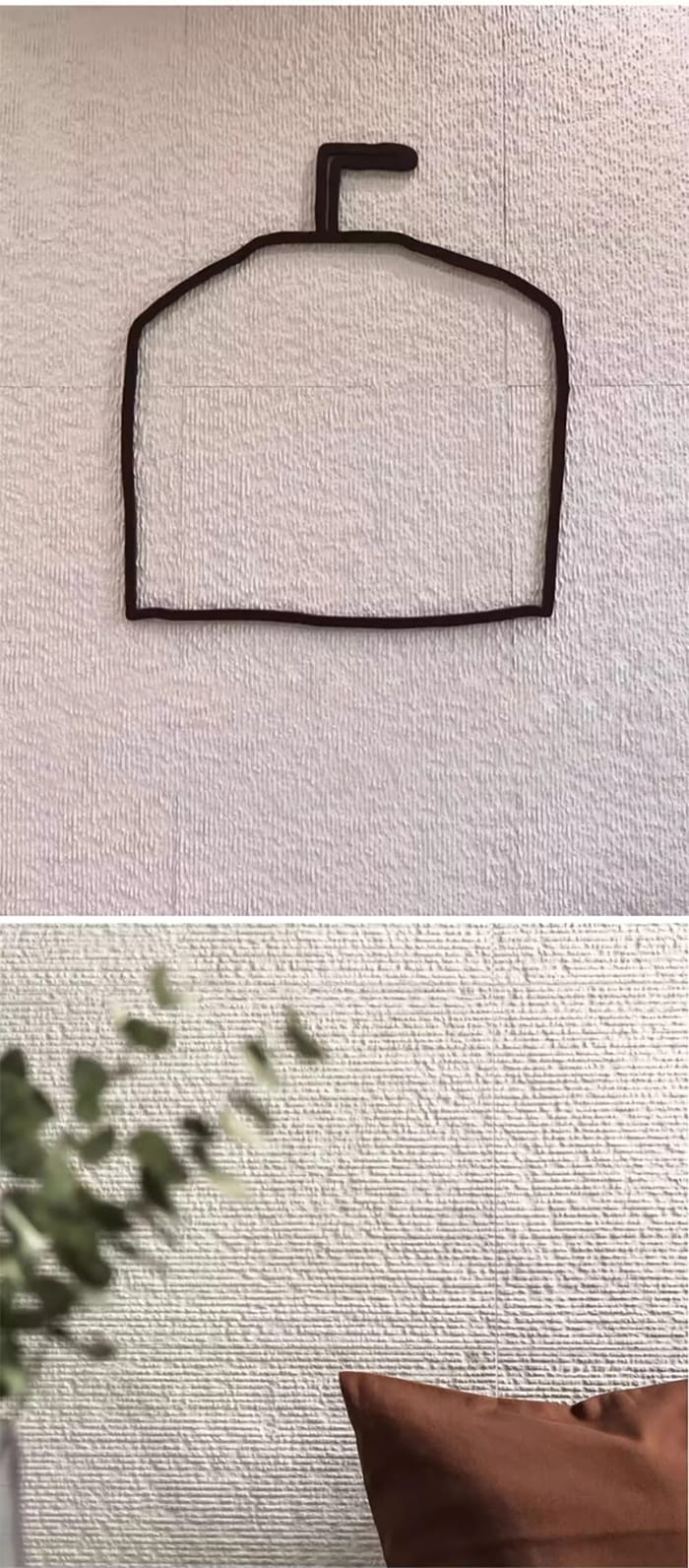

Curved/special-shaped structure : It can wrap 20cm diameter cylinders, arched columns, etc., and is suitable for minimalist, wabi-sabi and other design styles.

Old house renovationRenovation Project : No need to remove the original base surface (paint/tiles), direct wet-paste coverage, shortening the construction period by 50%.

Public Facilities

Hospital/Laboratory Antibacterial and mildew-proof (antibacterial rate ≥ 95%), chemical corrosion resistance (pH value 1-14).

Subway station/Airport : A1 fire protection + sound absorption and noise reduction (NRC ≥ 0.4), in line with public place safety standards.

Special scenarios

External wall insulation system : Composite insulation layer (thermal conductivity ≤ 0.045W/m·K), with significant energy-saving effect.

Pool/SPA Area: Water and alkali resistant (acid and alkali immersion resistant), adaptable to humid environment.

Ultra-thin and flexible

The thickness is only 3-15mm, and the bending radius can reach 20cm, which is suitable for curved walls and special-shaped structures.

Environmental safety

The inorganic raw materials are formaldehyde-free, radiation-free, meet ENF grade standards, and are 100% recyclable.

Imitation stone realistic

Replicate the texture of natural stone (such as travertine, star-moon stone, and cloth-grained stone), and the texture is no different from real stone.

Fire and moisture resistance

A1 grade non-flammable (some models are B1 grade), water absorption rate ≤0.5%, suitable for extreme climates.

Convenient construction

Direct wet pasting or gluing, no need for dry hanging keel, construction period is shortened by 50% and loss rate is low.

Durable and anti-aging

Freeze-thaw resistant (no powdering after 100 cycles), UV resistant (yellowing index ΔE≤1.5), with a service life of more than 30 years.

Economical The cost is only 30%-50% of natural stone, and the maintenance cost is low (no paint required, pollution-resistant).

Raw material preparation

Substrate Mixing : Stone powder (80-95%) + environmentally friendly resin/mesh cloth (5-20%), adding flame retardant (aluminum hydroxide) to improve the fire resistance level.

Surface coating : UV curing coating (film thickness ≥ 20μm) or antique glaze to enhance wear resistance and decorativeness.

Molding process

Compression Molding Special-shaped structures are pressed out by high temperature and high pressure (180-220℃), with an accuracy of ±0.5mm.

Composite structure : Surface layer (2-3mm soft stone) + base layer (5-10mm lightweight cement base material), hot-pressed into one piece.

Surface treatmentAntique treatment : Pickling, burning, litchi surface and other processes to simulate the weathering effect of natural stone.

Wood grain transfer : Laser engraved texture, clarity up to 1200dpi, adhesion ≥ grade 1 (ASTM D3359).

Quality Inspection

Fire test : Grade A1 (GB 8624 standard), flame spread time ≥ 60 minutes.

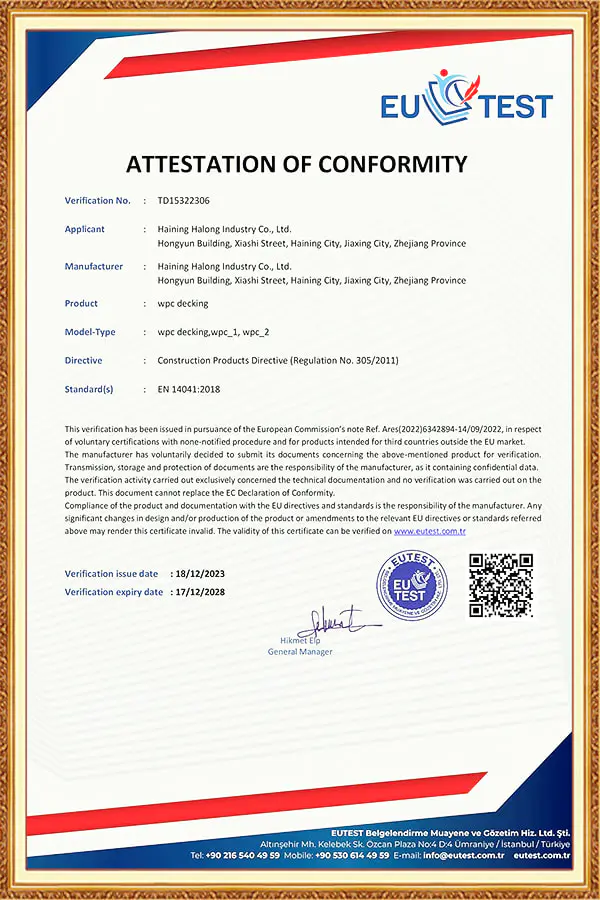

Environmental certification : Passed GREENGUARD Gold, FSC certification, CE certification (EU).

Physical properties :Impact strength ≥50kJ/m² (GB/T 1732 standard).

Construction technology

Grassroots processing Apply interface agent to ensure flatness error ≤3mm/2m.

Paving method : Use the dot-frame method to apply a special adhesive (water-powder ratio 1:4), leaving a gap of 6-8mm.

Special shape cutting: Use a utility knife or laser cutter, minimum thickness 3mm.

Established in 2005, our factory started with producing PVC Ceiling and Wall Panels, and has grown to be a professional China PVC ceiling panels manufacturer and a wholesale PVC panels factory, committed to providing our customers with high-quality products and services. After 20 years of development, we now own 5 large factories: Haining Halong PVC Ceiling Factory, Haining Longtime Film Factory, Guangxi PVC Wall Panel Factory, Indonesia PVC Wall Panel Factory, and Vietnam PVC Wall Panel Factory.

Our main products include: PVC Ceiling Panels, PVC Wall Panels, WPC Wall Panels, Hot Stamping Foil, PVC Lamination Film, SPC Flooring, WPC Decking, and other related products. Our annual sales can reach up to 35 million USD.

Industry Background and Application Importance In modern commercial and residential interior construction, wall panel systems are increasingly evaluated not only on aesthetics, but...

View MoreIndustry Background and Application Importance Decorative surface materials play a critical role in modern construction, interior systems, and modular building solutions. Tradition...

View MoreIndustry Background and Application Significance In modern construction, the choice of materials significantly impacts the durability, performance, and maintenance costs of a build...

View MoreRemoving PVC Self-Adhesive Wall Sticker from glass surfaces can be a challenging task if not approached correctly. The process requires understanding the adhesive properties, the t...

View More