Product name: PVC carbon crystal board (bamboo charcoal co-extruded decorative panel)

Specifications: Width: 1220mm;

Length: 2440mm/2600mm/2800mm/3000mm/3200mm/3500mm;

Height can be customized to 4m Thickness: 5mm, 8mm, 9mm, 20mm (customizable)

Density: 200~320kg/m³ (lightweight and high strength) Fire rating: B1

Flame-retardant standard: Waterproof and moisture-proof, non-absorbent, mildew-proof and moth-proof

Environmental performance: No formaldehyde added, in line with environmental protection standards

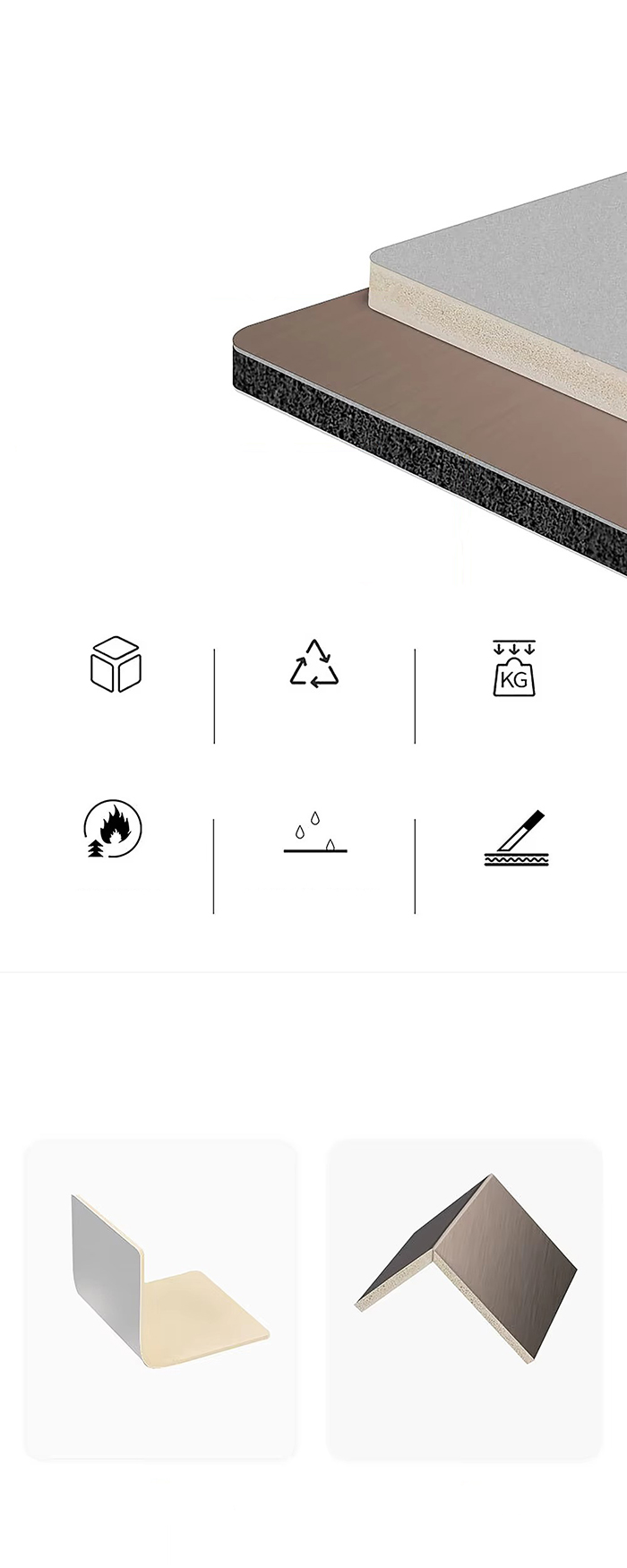

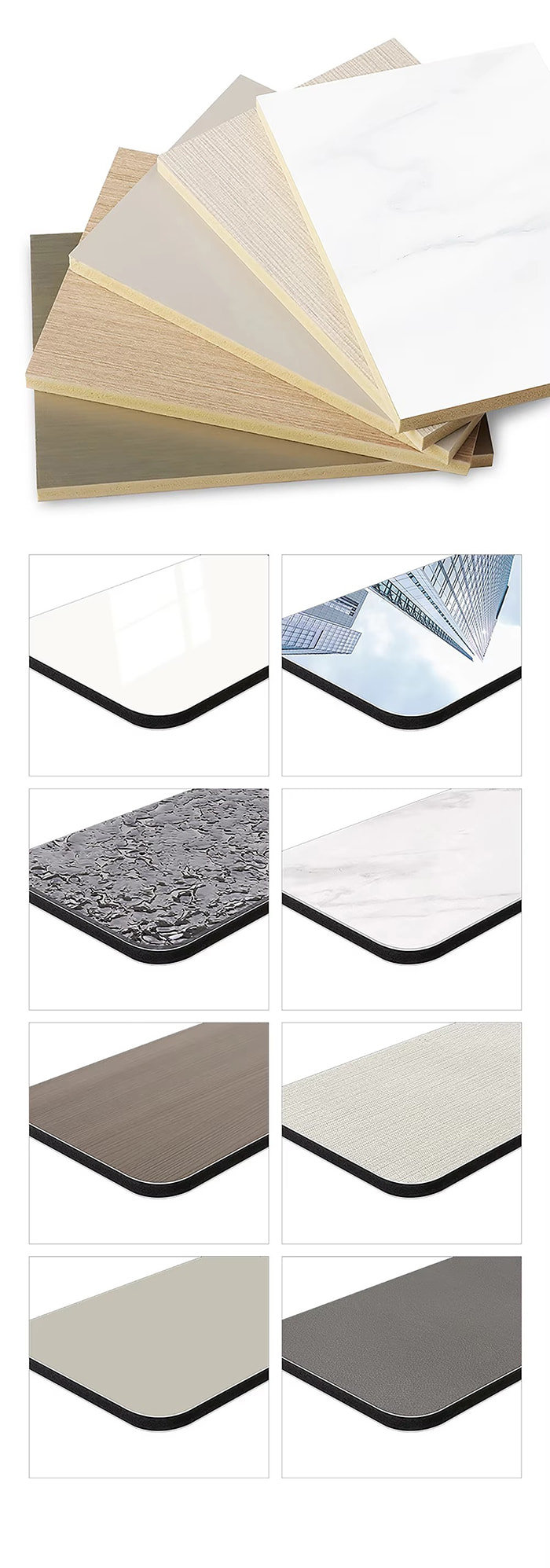

PVC carbon crystal board (scientific name "bamboo charcoal co-extruded decorative panel") is a wood-plastic composite material made by high-temperature extrusion process. The main raw materials include PVC resin, bamboo charcoal powder, calcium powder and additives. Its structure adopts multi-layer co-extrusion technology, usually including a protective layer, a decorative film layer, a light-cured layer, a PP co-extruded layer and a carbon crystal core layer. It has the characteristics of high hardness, wear resistance, moisture resistance, fire resistance, and environmental protection. Base material: PVC and bamboo charcoal powder are co-extruded to form a stable structure and not easy to deform. Surface treatment: It can be covered with a variety of decorative films such as wood grain, stone grain, and metal brushed to enhance the appearance. Environmental protection: It does not contain formaldehyde, there is no pollution during the production process, and it meets the standards of modern green building materials.

Application scenarios and scope of application

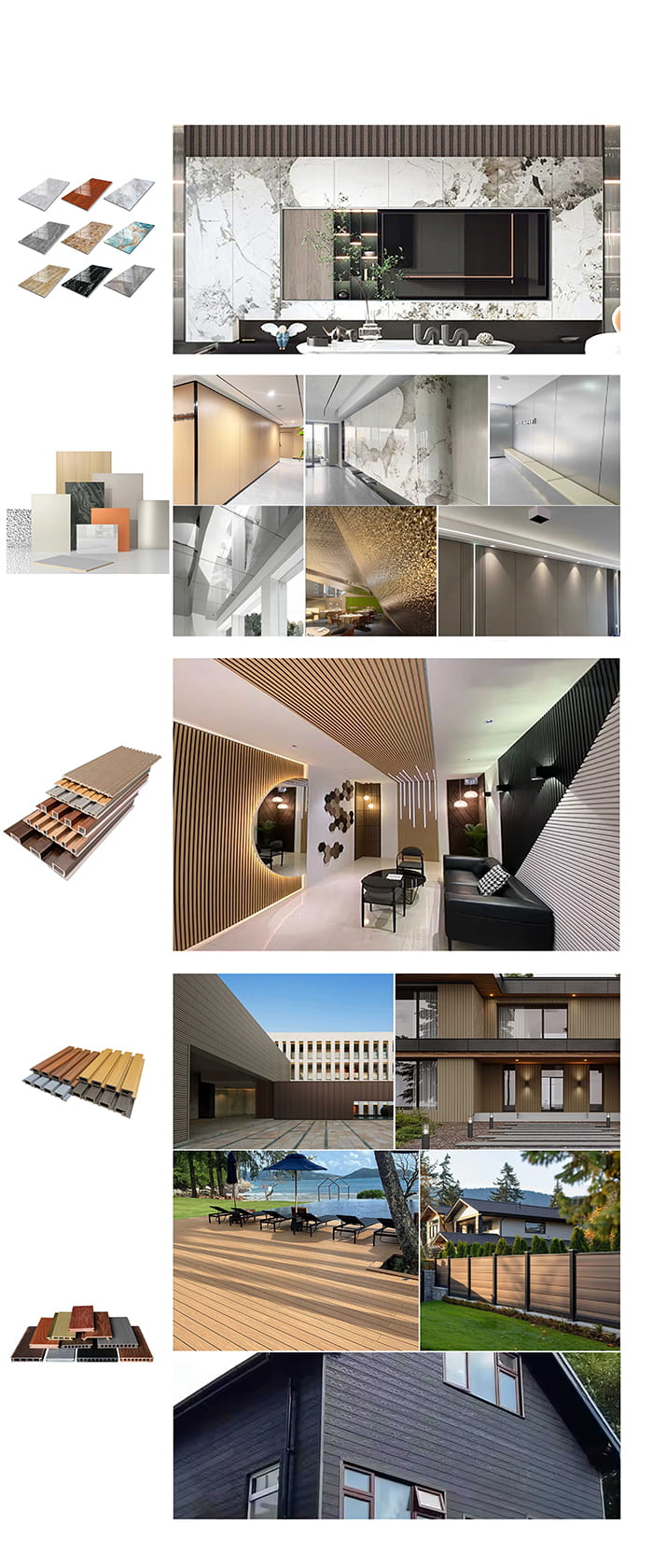

PVC carbon crystal panels are widely used in home, commercial space, public buildings and other fields, including:

(1) Home decoration wall decoration: replace traditional wallpaper and latex paint, used in living rooms, bedrooms, kitchens, bathrooms, etc. Wall panel: moisture-proof and mildew-proof, suitable for humid environments (such as bathrooms and basements). Ceiling: lightweight and fireproof, suitable for living rooms, corridors and other areas.

(2) Commercial space hotels and offices: modular installation, short construction period, and customizable high-end decorative effects. Shopping malls and exhibition halls: wear-resistant and scratch-resistant, suitable for high-traffic areas.

(3) Public buildings hospitals and schools: fire retardant (B1 grade), in line with safety standards. Subway stations and airports: strong weather resistance, suitable for large space decoration.

Product Features/Advantages

Features

Advantages

Description

Environmentally friendly and formaldehyde-free

No formaldehyde-containing adhesives are used in the production process, which meets the standards for healthy homes.

Fire retardancy meets the B1 flame retardant standard and is suitable for places with strict fire protection requirements.

Moisture-proof, mildew-proof and non-absorbent, suitable for humid environments such as bathrooms and basements.

High hardness and wear-resistant surface with high hardness, scratch resistance and long service life.

Easy to installModular gusset design, fast construction, can be directly installed on the rough wall.

Rich colors and patterns can be customized with a variety of finishes such as wood grain, stone grain, and metal brushing to meet different style requirements.

Light weight and earthquake-resistantThe weight is only 1/10 of that of traditional building materials, suitable for high-rise buildings and steel structure factories

Technology and process

(1) Production process Co-extrusion: Using a twin-screw extruder (such as SJZ80/156), PVC, bamboo charcoal powder, calcium powder and other raw materials are melted at high temperature and extruded through a mold16. Film coating technology: The surface is coated with PUR hot melt adhesive to ensure that the film layer is firmly attached and not easy to fall off.

(2) Key equipment Extruder: Conical twin-screw extruder (such as SJZ80/156) to ensure high output (450kg/h)6. Shaping and cooling: Using a water-cooled shaping table + vacuum adsorption to ensure the flatness of the board. Cutting and material collection: Automatic cutting machine + robot unloading to improve production efficiency.

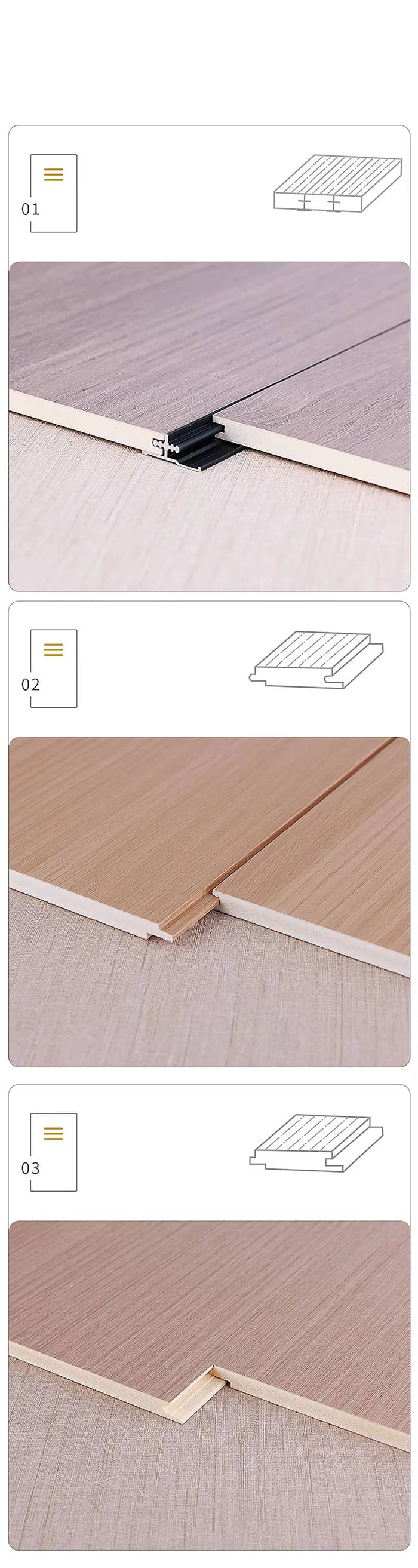

(3) Construction process Wall treatment: Leveling is required, and wooden keels or direct gluing can be used for installation. Splicing method: Use mother-and-child grooves and metal closing strips for seamless splicing. Closing treatment: The internal and external corners can be curved or profile closing strips can be used to optimize the aesthetics8.

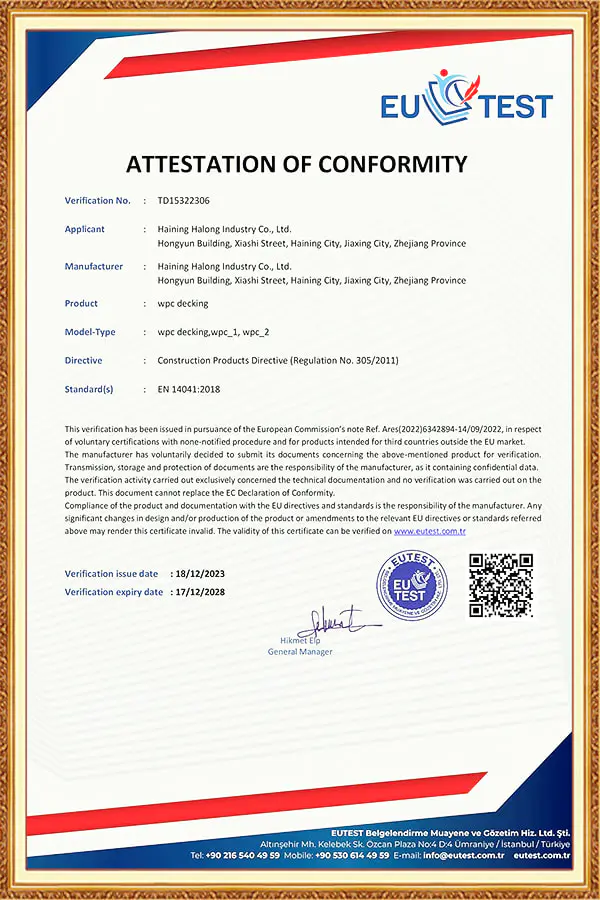

Established in 2005, our factory started with producing PVC Ceiling and Wall Panels, and has grown to be a professional China PVC ceiling panels manufacturer and a wholesale PVC panels factory, committed to providing our customers with high-quality products and services. After 20 years of development, we now own 5 large factories: Haining Halong PVC Ceiling Factory, Haining Longtime Film Factory, Guangxi PVC Wall Panel Factory, Indonesia PVC Wall Panel Factory, and Vietnam PVC Wall Panel Factory.

Our main products include: PVC Ceiling Panels, PVC Wall Panels, WPC Wall Panels, Hot Stamping Foil, PVC Lamination Film, SPC Flooring, WPC Decking, and other related products. Our annual sales can reach up to 35 million USD.

Industry Background and Application Importance In modern commercial and residential interior construction, wall panel systems are increasingly evaluated not only on aesthetics, but...

View MoreIndustry Background and Application Importance Decorative surface materials play a critical role in modern construction, interior systems, and modular building solutions. Tradition...

View MoreIndustry Background and Application Significance In modern construction, the choice of materials significantly impacts the durability, performance, and maintenance costs of a build...

View MoreRemoving PVC Self-Adhesive Wall Sticker from glass surfaces can be a challenging task if not approached correctly. The process requires understanding the adhesive properties, the t...

View More