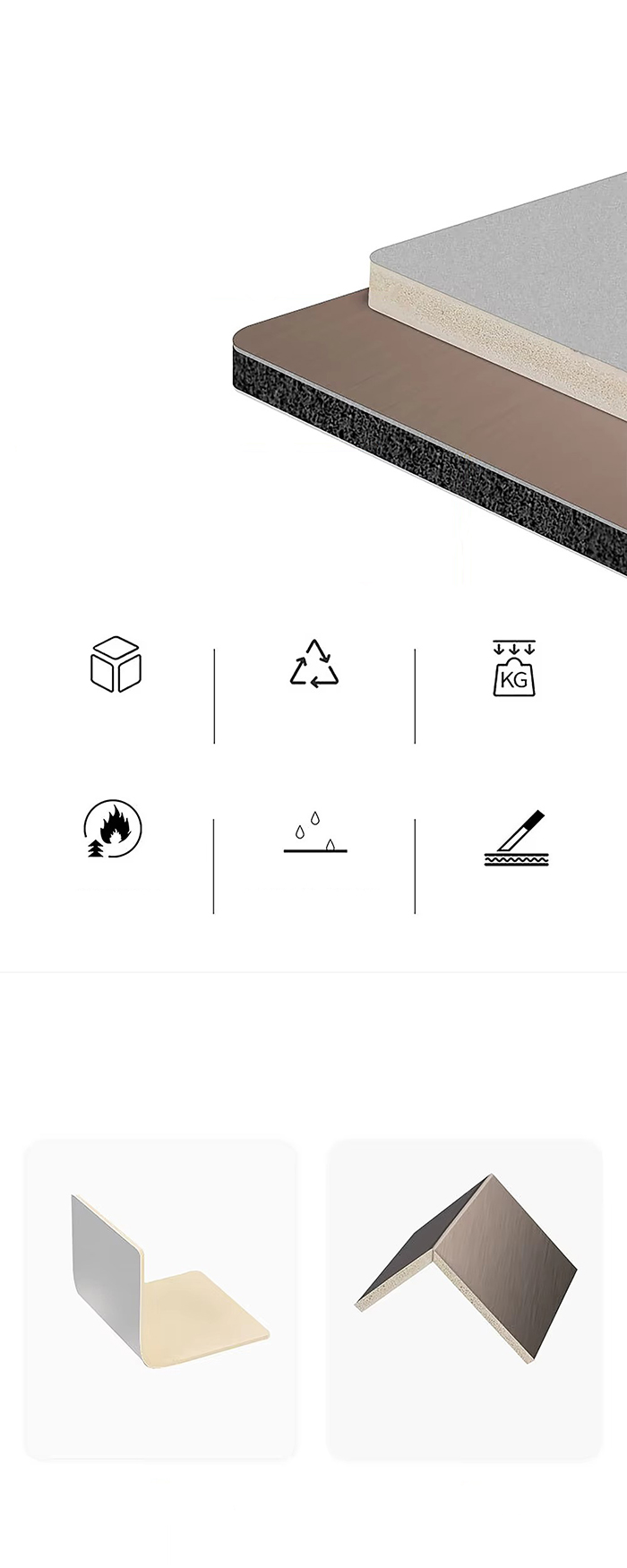

Material

High-density PVC substrate + wood grain/stone grain/skin-feel film surface coating

Size

Standard specifications: 1220mm×2440mm (support customized width ≤1220mm, length ≤3000mm) thickness 3mm-20mm (conventional thickness: 3mm, 5mm, 8mm)

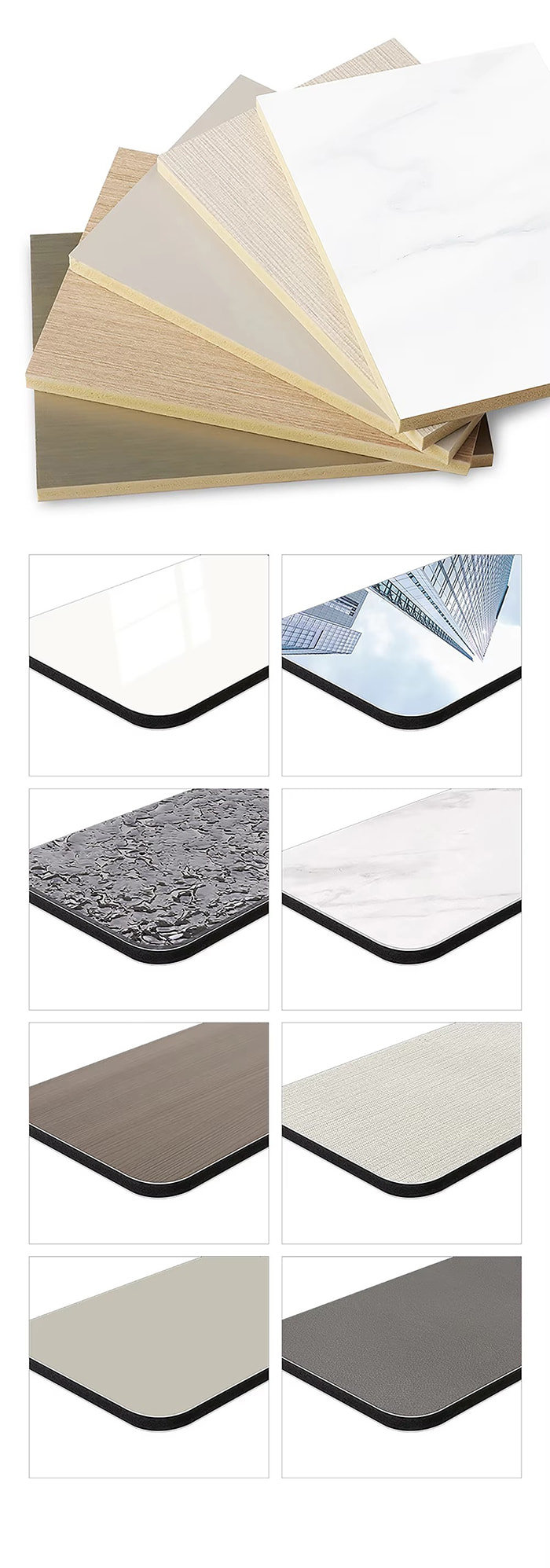

Surface texture High-definition wood grain (oak, walnut, maple, etc.), stone grain, cloth grain, skin-feel imitation wood, etc. (supports high-definition customization)

Color

Natural wood color (such as cherry wood color, teak color), customized color (Pantone color number is required)Surface hardness

Pencil hardness ≥1H (ASTM D3363 standard), scratch resistance

Moisture resistance Water absorption rate <0.3% (ASTM D570 standard), suitable for humid environment

Environmental standards Comply with CARB certification, FSC forest certification, formaldehyde emission ≤ 0.05mg/m³ (EN 717-1 standard)Fire rating B1 flame retardant (GB 8624 standard)

PVC wood veneer is a decorative material that uses high-density PVC as the base material and reproduces natural wood grain, stone grain and other textures on the surface through hot pressing lamination or digital printing technology. Its surface adopts environmentally friendly UV coating or PET lamination, which combines the natural texture of solid wood with the waterproof and moisture-proof properties of PVC. It can be directly installed without painting. It is suitable for indoor and outdoor walls, furniture, cabinets and other scenes, and is a cost-effective choice to replace traditional solid wood panels.

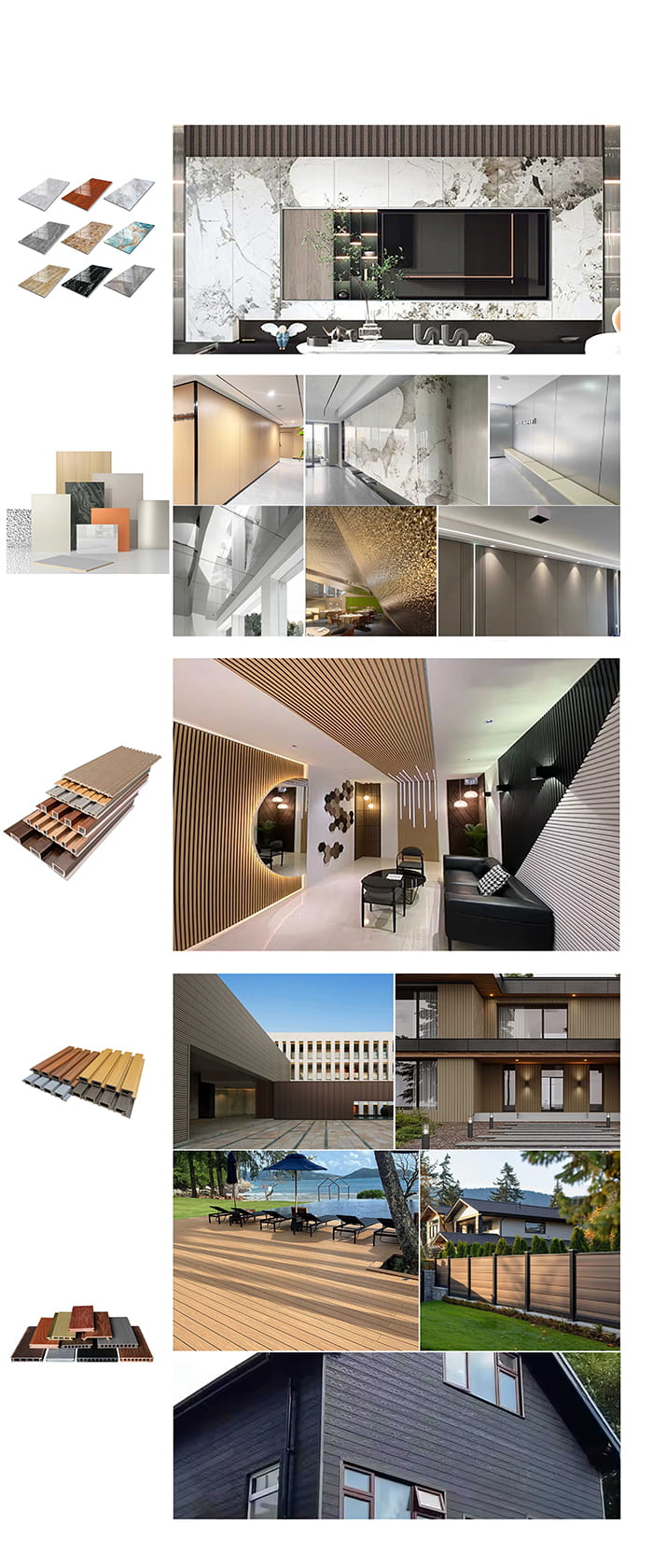

Application scenarios and scope of applicationInterior decoration

Wall/ceiling : Imitation wood veneer background wall in living room, bedroom and hotel lobby.

Cabinets/Wardrobe : Moisture-proof and stain-resistant, maintenance-free, suitable for humid areas such as kitchens and bathrooms.

Children's Room Furniture : Environmentally friendly, formaldehyde-free, rounded corner anti-collision design, high safety.

Advantages : Zero formaldehyde, easy to clean, moisture-resistant and mildew-proof.

Commercial SpaceShopping mall/showroom : Imitation wood grain walls enhance the texture of the space and are lightweight and easy to install.

Chain Stores : Standardized production, supports quick replacement, and adapts to a variety of decoration styles.

Advantages : Wear-resistant and scratch-resistant, long-lasting color, support customized LOGO printing.

Public FacilitiesHospital/School : Antibacterial and mildew-proof surface, antibacterial rate ≥ 99% (GB/T 21551.2 standard).

Subway station/Airport : Fireproof and moisture-proof, suitable for high traffic areas.

Advantages : Strong weather resistance, impact resistance and long service life.

Outdoor sceneSun room/terrace : Anti-UV coating, weather resistance for more than 5 years (ASTM G154 standard).

Landscape : Imitation wood railings and flower stands, lightweight and maintenance-free.

AdvantagesHigh and low temperature resistance (-20℃ to 60℃), anti-aging.

Product Features/Advantages

Realistic wood effect The high-definition wood grain resolution reaches 1200dpi, and the texture level is consistent with real wood, with no color difference.

Environmental safety It is formaldehyde-free and heavy metal-free, complies with international environmental standards (CARB/FSC), and is suitable for children's rooms and hospitals.Moisture and stain resistant The surface coating is waterproof, acid and alkali resistant (pH 3-11), and can be cleaned by wiping with a damp cloth.

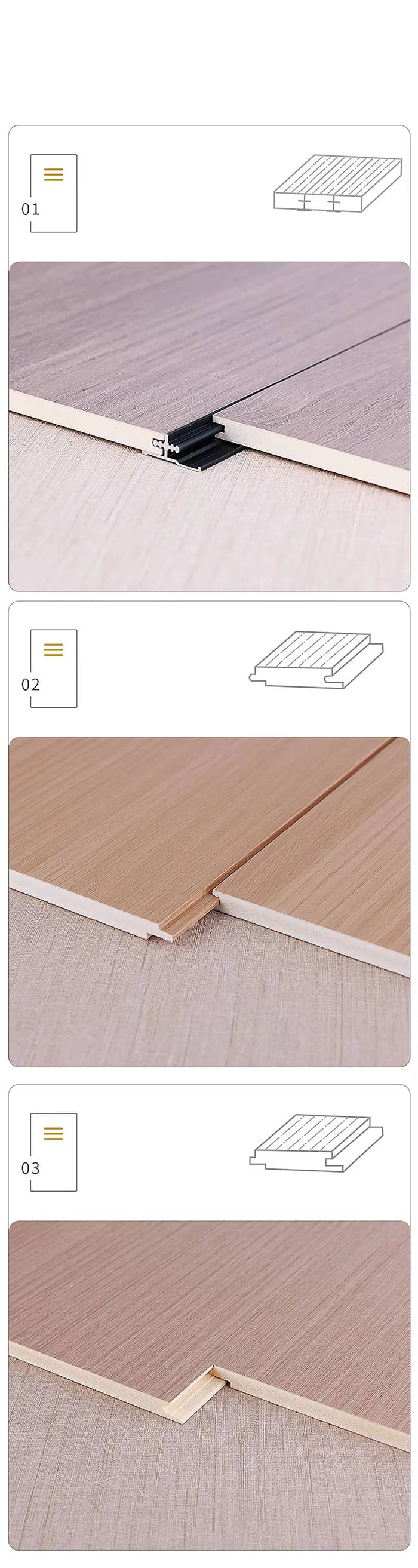

Easy installation Lock-and-lock splicing or nail-free glue installation, no keel required, saving labor costs.

Diversified Design Supports special-shaped cutting (laser cutting accuracy ±0.1mm), suitable for curved walls and furniture corners.High cost performance

The cost is only 1/3 of that of solid wood, the service life can reach more than 10 years, and the maintenance cost is low

Technology and craftsmanship

Substrate treatmentIt uses high-density PVC foam board (XPE/IXPE) with internal closed-cell structure to enhance impact resistance.

Surface coating processHot pressing lamination : The PET wood grain film is bonded to the substrate under high temperature and high pressure, and the surface wear resistance is increased by 50%.

Digital Printing : UV inkjet technology achieves high-definition texture and supports small batch customization.

Environmentally friendly coating technology The surface is coated with nano-scale UV-curable resin, which is scratch-resistant and yellowing-resistant (QUV aging test ≥ 500 hours).

Edge Processing Laser edge banding or PUR edge banding technology prevents glue from overflowing and ensures smooth edges to prevent debonding.

Customized service Support customized texture, color and size according to drawings and samples, and fast proofing within 7-15 days.

Established in 2005, our factory started with producing PVC Ceiling and Wall Panels, and has grown to be a professional China PVC ceiling panels manufacturer and a wholesale PVC panels factory, committed to providing our customers with high-quality products and services. After 20 years of development, we now own 5 large factories: Haining Halong PVC Ceiling Factory, Haining Longtime Film Factory, Guangxi PVC Wall Panel Factory, Indonesia PVC Wall Panel Factory, and Vietnam PVC Wall Panel Factory.

Our main products include: PVC Ceiling Panels, PVC Wall Panels, WPC Wall Panels, Hot Stamping Foil, PVC Lamination Film, SPC Flooring, WPC Decking, and other related products. Our annual sales can reach up to 35 million USD.

Introduction to Core Construction in wpc fence panels When selecting materials for a fencing project, professionals and wholesalers must make informed decisions based on a deep und...

View MoreWhen selecting materials for a construction or renovation project, professionals and homeowners alike delve into the specifications that define a product’s quality and suitability....

View MoreIn today’s construction and interior design market, efficiency, durability, and cost-effectiveness are critical factors when selecting wall materials. Among the many solutions avai...

View MoreFrom first handshake to final contract, these smiles built our best Canton Fair ever. Swipe to see the faces that will cover 1 million m2 next year. Grateful. Growing. Global. #Cus...

View More