MaterialInorganic mineral powder, etc.

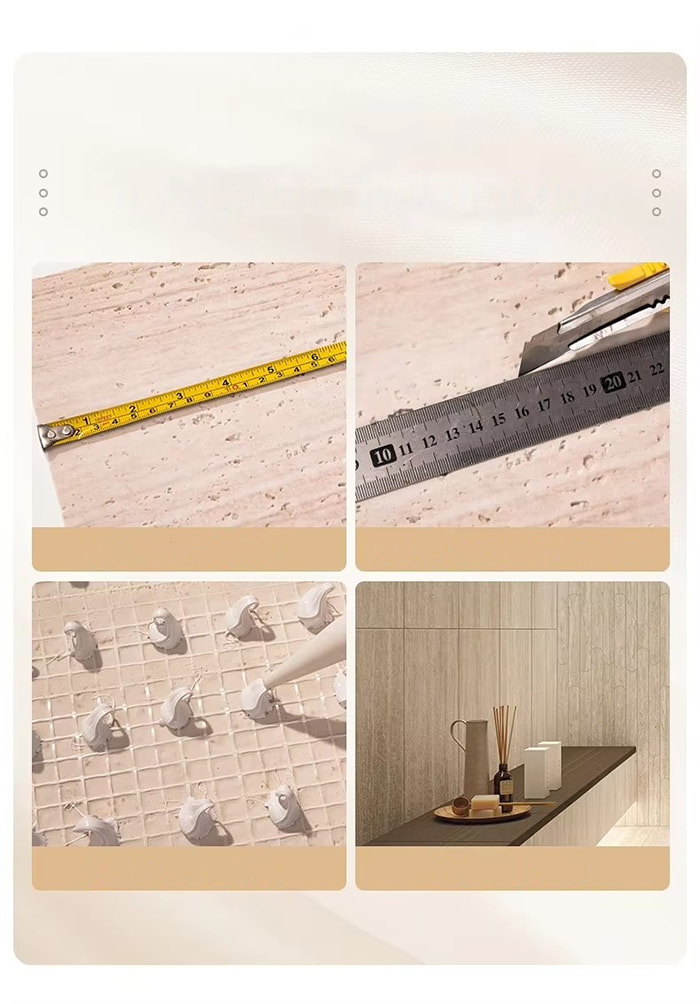

Thickness2-10mm

Size can be customized, common sizes are 1200×600mm, 600×300mm, 600×1200mm, etc.

Colors

Gray, black, maroon, white, yellow, off-white, dark gray, light gray, medium gray, brick red, etc., can also be customized

Surface treatment

Can present a variety of textures and textures such as wood grain, stone, weaving, split bricks

Fireproof performance

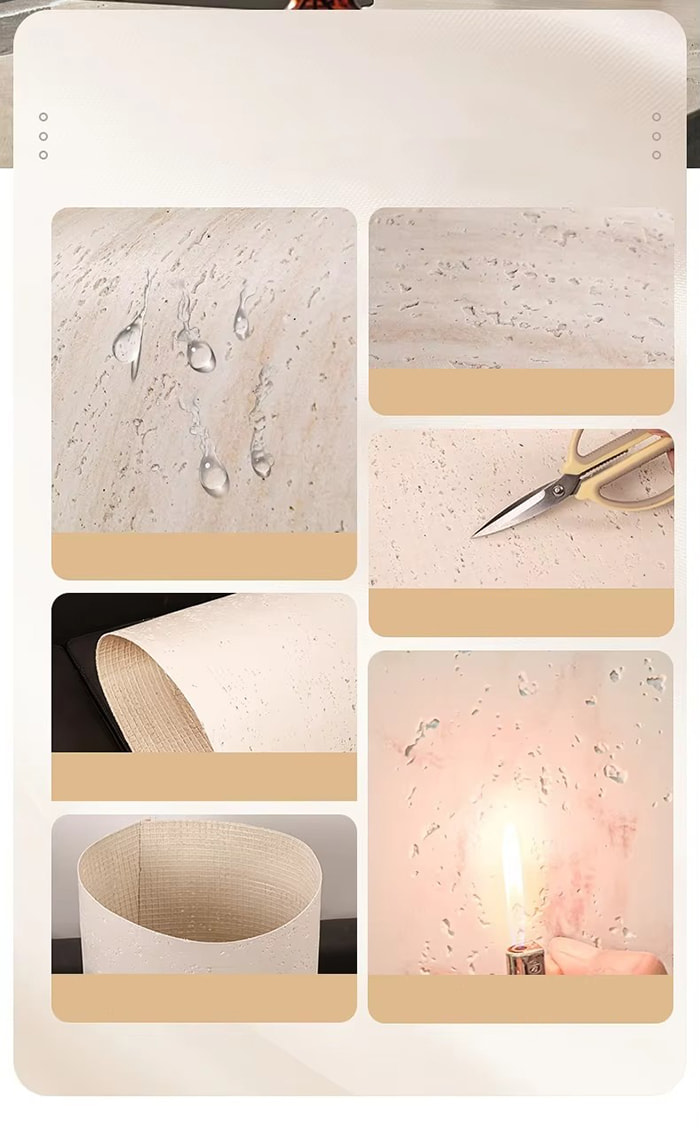

A-level fireproof standard

Waterproof performance

Waterproof, breathableImpact resistance

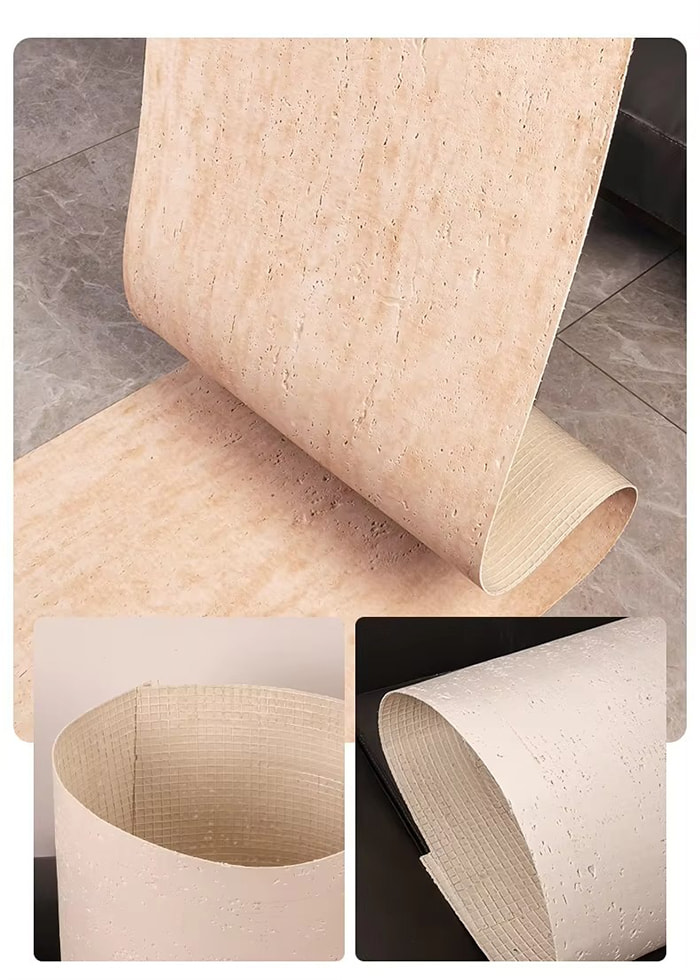

With a certain degree of flexibility, bendable, strong ductility

Formaldehyde release

Odorless, non-toxic, no radiation

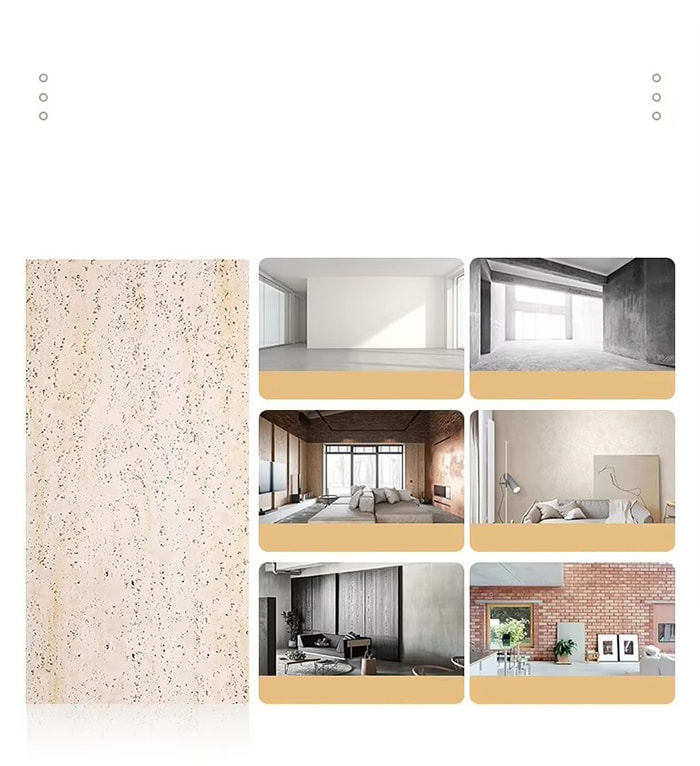

ApplicationIndoor and outdoor walls, floors, old wall renovation, thermal insulation wall finishing decoration, etc.

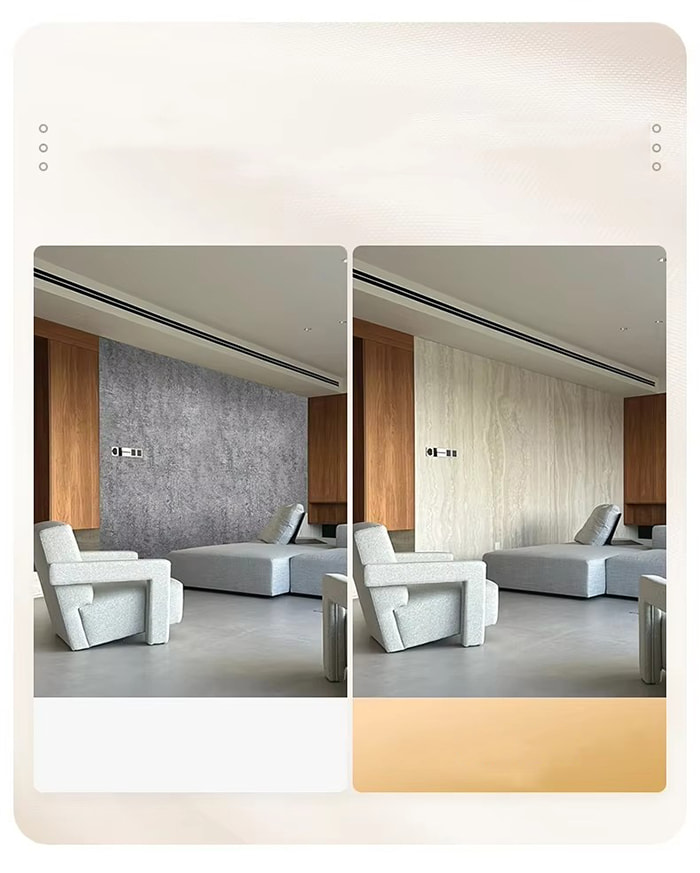

Soft stone wall panels are a new type of flexible imitation stone material, with inorganic materials as the base material, added with environmentally friendly water-soluble architectural coatings, and made through processes such as irradiation cross-linking and baking molding. It has the characteristics of being ultra-thin and bendable, and can present a realistic stone effect. At the same time, the color is long-lasting and will not fade, bulge, fall off, or powder due to ultraviolet radiation or other external natural conditions. It has excellent durability. Soft stone wall panels can not only realistically show the color and texture of existing materials such as stone, wood, leather, and weaving, but also create personalized textures according to design requirements to meet the design needs of various special-shaped buildings.

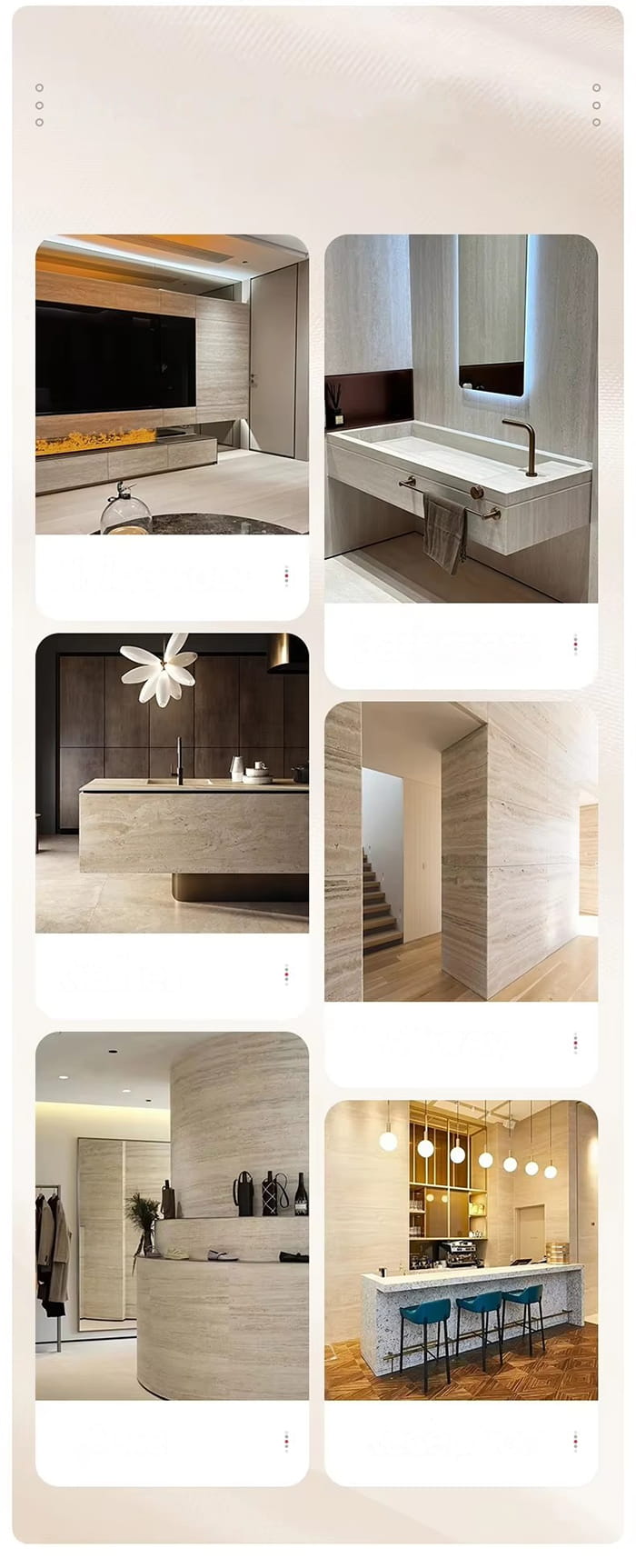

Building exterior walls: Suitable for exterior finishing projects of high-rise buildings, exterior wall materials for urban renovation, finishing layers of external insulation systems, and finishing projects of special-shaped buildings such as curved walls and arched columns.

Building interior walls: Can be used for interior wall decoration of residences, offices, hotels, shopping malls, schools, hospitals, office buildings, villas, high-end communities, etc., such as background walls, kitchens, bathrooms and other spaces.

Floor and old wall renovation: Can be used for floor decoration and old wall renovation, without knocking off the old base surface, easy construction, no garbage output, short construction period, saving construction costs.

Performance advantages: Lightweight and high strength: thin thickness, weighing only 3.5-4kg per square meter, saving space and cement, easy to transport and install. Fireproof and moisture-proof: meets Class A fireproof standards, waterproof and breathable.

Strong weather resistance: acid and alkali resistance, freeze-thaw resistance, UV resistance, and can withstand the test of severe weather.

Earthquake and crack resistance: has good flexibility and can withstand thermal stress deformation of building structures and different insulation bases.

Decorative advantages:

Rich texture: can present a variety of textures and textures such as wood grain, stone, weaving, split bricks, etc., and can also customize personalized textures according to design requirements.

Lasting color: the color comes from the material itself, and pure natural colors are more durable.

Easy to clean: the surface of the product has super hydrophilicity, and it can quickly form a water film when encountering rain, making it difficult for dirt to adhere and be washed away with rain.

Cost-effectiveness advantage:

Convenient construction: easy installation, firm pasting, convenient cutting, no need for professional equipment.

Controllable cost: the price is relatively low, and the construction period is short, which can greatly save labor costs.

Green and environmentally friendly: using natural modified mineral powder as raw material, there is no need to blast mountains and split rocks, reducing the pollution of industrial waste to the environment, and there is no dust, noise and other pollution during construction.

Production process: Inorganic mineral powder is used as the main raw material, and it is made through irradiation cross-linking, baking and molding under a dynamic temperature curve.

Surface treatment process: Various surface treatments can be performed, such as spraying, engraving, etc., to present different textures and textures to meet different decorative needs.

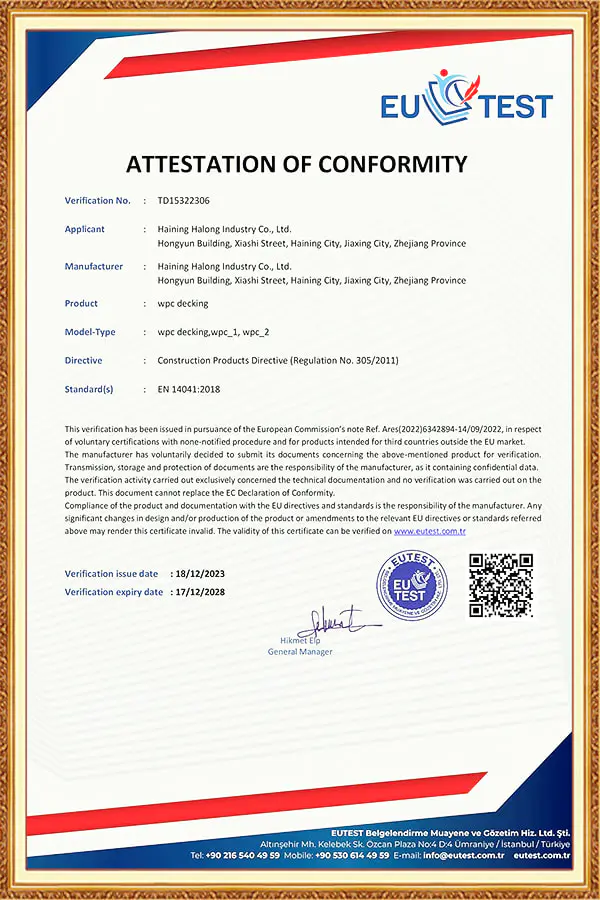

Established in 2005, our factory started with producing PVC Ceiling and Wall Panels, and has grown to be a professional China PVC ceiling panels manufacturer and a wholesale PVC panels factory, committed to providing our customers with high-quality products and services. After 20 years of development, we now own 5 large factories: Haining Halong PVC Ceiling Factory, Haining Longtime Film Factory, Guangxi PVC Wall Panel Factory, Indonesia PVC Wall Panel Factory, and Vietnam PVC Wall Panel Factory.

Our main products include: PVC Ceiling Panels, PVC Wall Panels, WPC Wall Panels, Hot Stamping Foil, PVC Lamination Film, SPC Flooring, WPC Decking, and other related products. Our annual sales can reach up to 35 million USD.

Industry Background and Application Importance In modern commercial and residential interior construction, wall panel systems are increasingly evaluated not only on aesthetics, but...

View MoreIndustry Background and Application Importance Decorative surface materials play a critical role in modern construction, interior systems, and modular building solutions. Tradition...

View MoreIndustry Background and Application Significance In modern construction, the choice of materials significantly impacts the durability, performance, and maintenance costs of a build...

View MoreRemoving PVC Self-Adhesive Wall Sticker from glass surfaces can be a challenging task if not approached correctly. The process requires understanding the adhesive properties, the t...

View More