Material: Polyvinyl chloride (PVC) Thickness: 100 microns, 120 microns, 18 microns (base film thickness)

Size:

Width: 30.5cm, 61cm; Length: 25m, etc.

Color: Various colors are available, such as white Surface treatment: scratch-resistant coating, antibacterial coating; matte effect

Transfer temperature: 150-160℃

Transfer pressure: 0.2kgf/cm²

Transfer time: 5-10 seconds

Shelf life: 2 years

Storage conditions:

Temperature: -5℃~40℃,

humidity: 20%~85%, ventilation, avoid light, away from heat sources

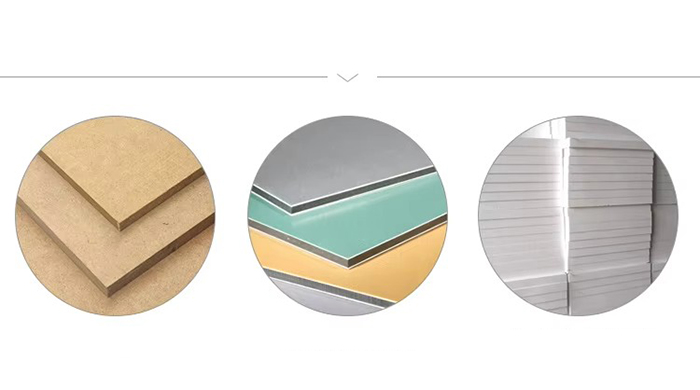

PVC transfer film is a medium material used in thermal transfer process. It is made of polyvinyl chloride (PVC) and has good flexibility and elasticity. It usually consists of a multi-layer structure, including a base film, a decorative layer, a protective layer, a base color layer, a release layer and a hot melt adhesive layer. This material can transfer the pattern to the surface of various substrates by heat pressing to form a surface layer with decorative effect.

Apparel: Suitable for customizing T-shirts, hoodies, sweatshirts, canvas bags, pillowcases, hats, etc.

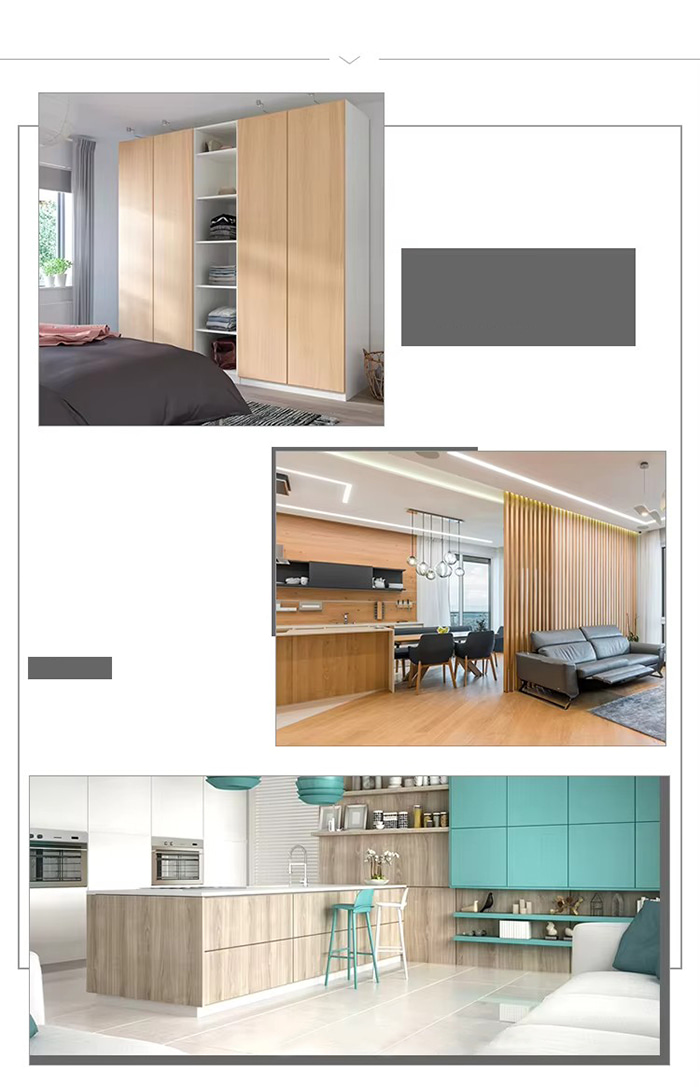

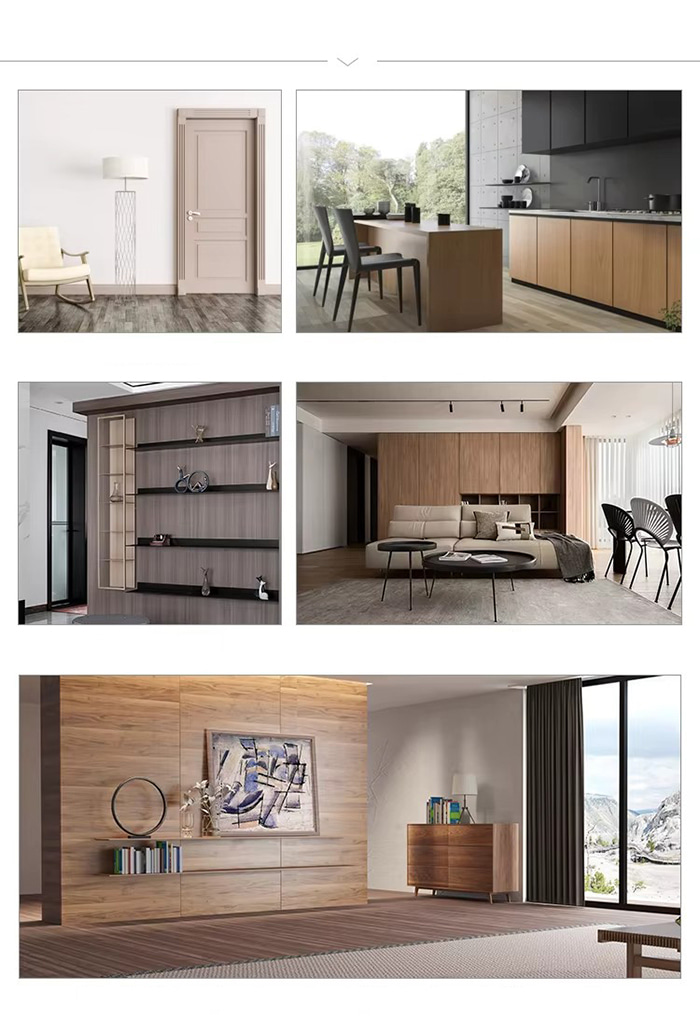

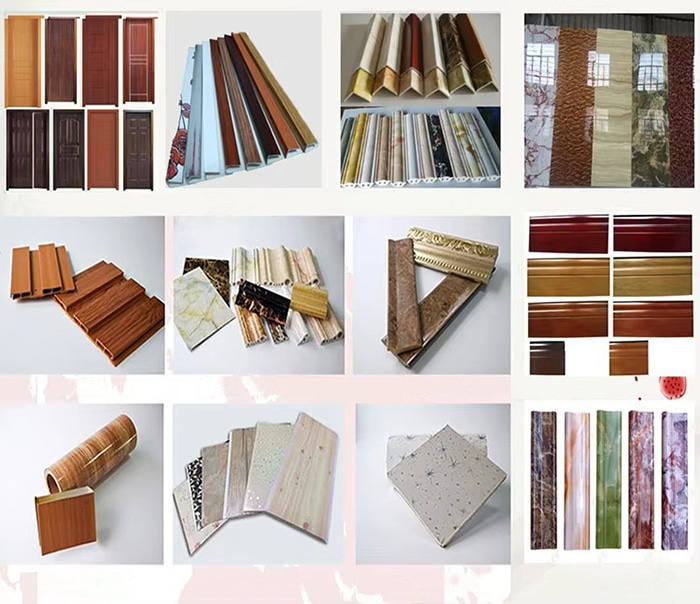

Home decoration: Can be used for surface decoration of furniture, cabinets, wooden doors, etc.

Medical field: Such as PVC infusion soft bag thermal transfer film, supporting the field of large medical infusion, suitable for PVC film information identification, can meet the ultra-long time high temperature sterilization production process.

Advertising logo: Can be used to make advertising logos, labels, etc.

Other fields: Can also be used in toys, wire sheaths, adhesive films, etc.

Performance advantages:

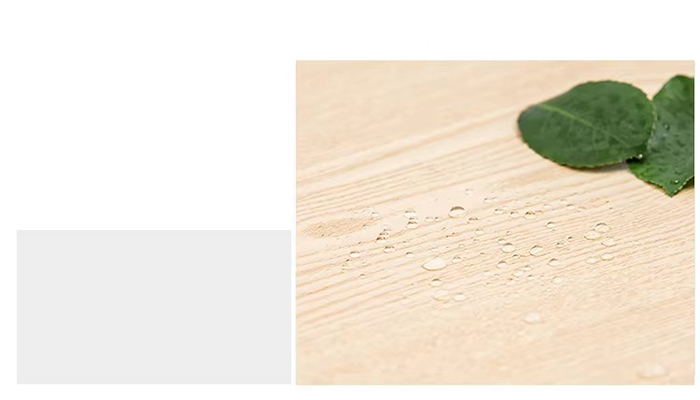

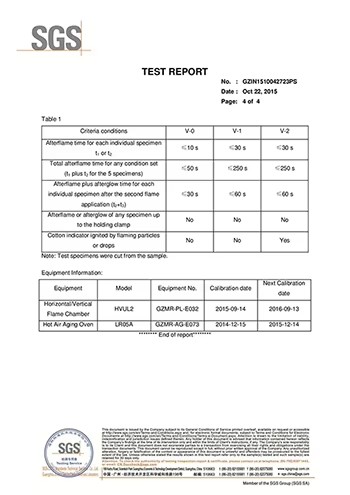

Friction resistance: The print has strong friction resistance, and the number of times it is rubbed ≥ 200 times.

Boiling resistance: After 90 minutes of boiling at 121℃, there is no secondary transfer of the print.

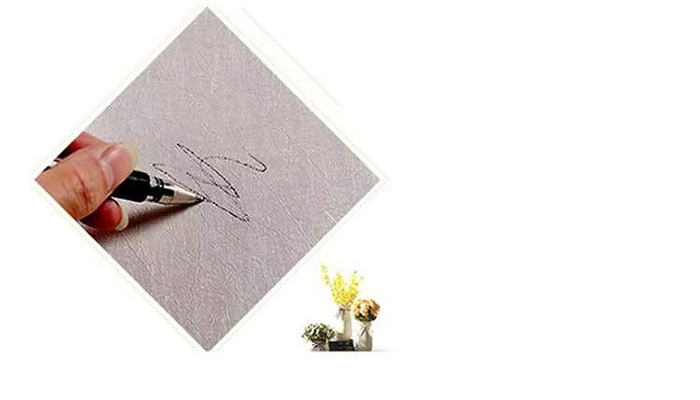

Ethanol resistance: After soaking in 75% medical alcohol for 30 minutes, the print lines are clearly defined, without missing pens or broken strokes, burrs, ink clumps, or hollows.

Anti-adhesion: During continuous printing, the printed film and the substrate are separated by themselves during visual inspection.

Decorative advantages:

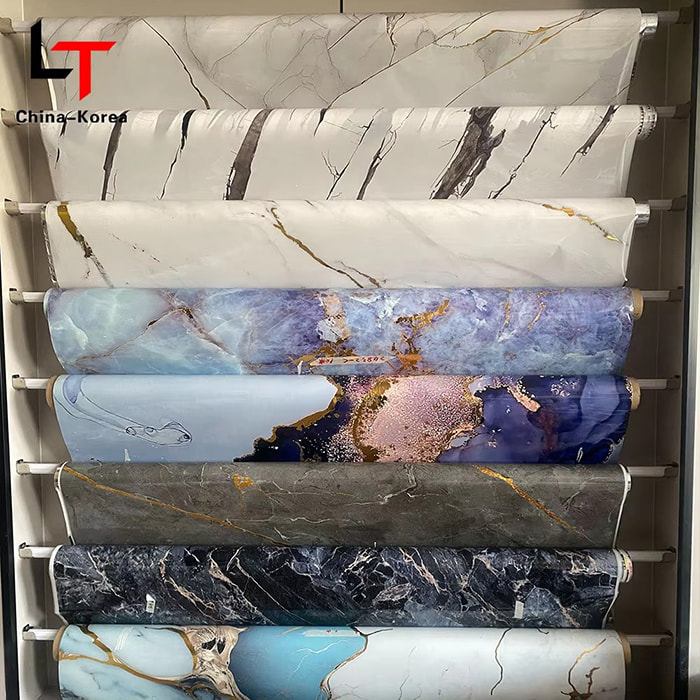

Rich colors: Various patterns can be printed, such as wood grain, stone grain, etc., with realistic decorative effects.

Diverse colors: There are a variety of colors to choose from.

Cost-effectiveness advantage:

Affordable price: Compared with other materials, PVC transfer film is cheaper.

Simple process: The thermal transfer process is simple and efficient.

Production process:

The production of PVC transfer film usually includes base film preparation, coating printing, hot pressing and other steps.

The decorative layer, protective layer, etc. are separated from the base film and transferred to the target substrate surface by hot pressing.

Surface treatment process: The surface is usually treated with scratch resistance, antibacterial and other treatments to improve the wear resistance and service life of the product.

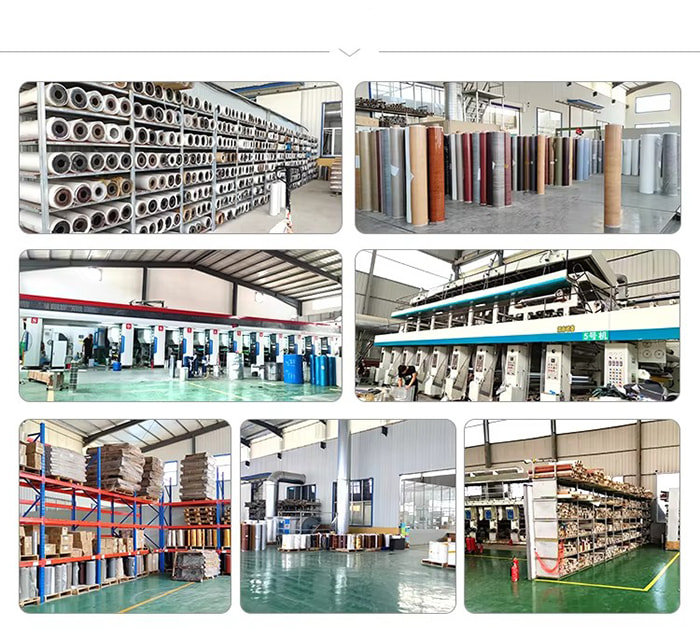

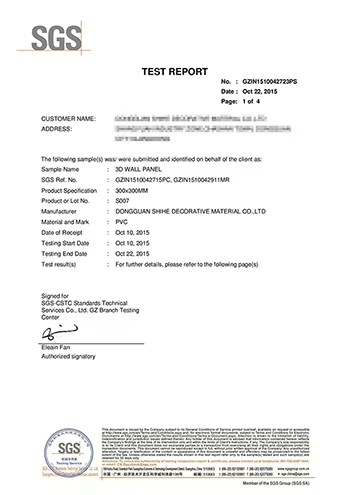

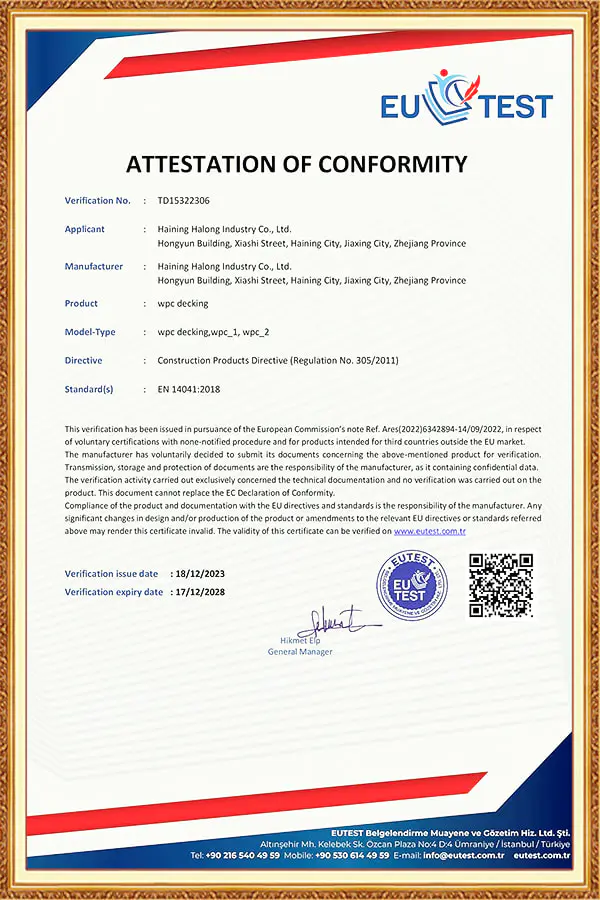

Established in 2005, our factory started with producing PVC Ceiling and Wall Panels, and has grown to be a professional China PVC ceiling panels manufacturer and a wholesale PVC panels factory, committed to providing our customers with high-quality products and services. After 20 years of development, we now own 5 large factories: Haining Halong PVC Ceiling Factory, Haining Longtime Film Factory, Guangxi PVC Wall Panel Factory, Indonesia PVC Wall Panel Factory, and Vietnam PVC Wall Panel Factory.

Our main products include: PVC Ceiling Panels, PVC Wall Panels, WPC Wall Panels, Hot Stamping Foil, PVC Lamination Film, SPC Flooring, WPC Decking, and other related products. Our annual sales can reach up to 35 million USD.

Industry Background and Application Importance Decorative surface materials play a critical role in modern construction, interior systems, and modular building solutions. Tradition...

View MoreIndustry Background and Application Significance In modern construction, the choice of materials significantly impacts the durability, performance, and maintenance costs of a build...

View MoreRemoving PVC Self-Adhesive Wall Sticker from glass surfaces can be a challenging task if not approached correctly. The process requires understanding the adhesive properties, the t...

View MoreThe flooring industry has witnessed significant advancements in recent years, with new materials offering improved durability, aesthetics, and ease of installation. Among these inn...

View More