Material Polyvinyl chloride (PVC) base film + transfer ink layer + protective coating (UV/matte/gloss)

Size

Standard width: 1220mm / 1530mm;

length: 50m/roll (support customized width ≤1530mm, length ≤1000m)

Thickness 0.08mm-0.5mm (conventional thickness: 0.12mm, 0.2mm, 0.3mm)

Printing resolution Up to 1200dpi (laser engraving accuracy up to 0.01mm)color

Transparent, porcelain white, wood grain, stone grain, metallic color, gradient effect (support Pantone color customization)

Wear resistance ≥5000 revolutions (Taber wear test, CS-10 wheel, load 1kg)

Temperature resistance -30℃ to 80℃ (no warping or fading during long-term use)

Tensile strength ≥18MPa (longitudinal) / ≥12MPa (transverse) (GB/T 1040 standard)

Peel strength ≥15N/cm (bonding force between PET substrate and transfer layer, ASTM D3359)

Environmental standards Compliant with RoHS, REACH, EN71-3 (heavy metal ≤ 0.01mg/kg)

PVC transfer film is a decorative material that uses polyvinyl chloride (PVC) film as the substrate, transfers the pattern layer to the substrate surface through high-precision printing, vacuum transfer or laser engraving technology, and then covers it with UV coating or protective film. Its core features include high-precision pattern restoration, wear resistance and weather resistance, environmental protection and non-toxicity. It is suitable for surface decoration of furniture, building materials, electronic products, etc., replacing traditional spraying and sticker processes.

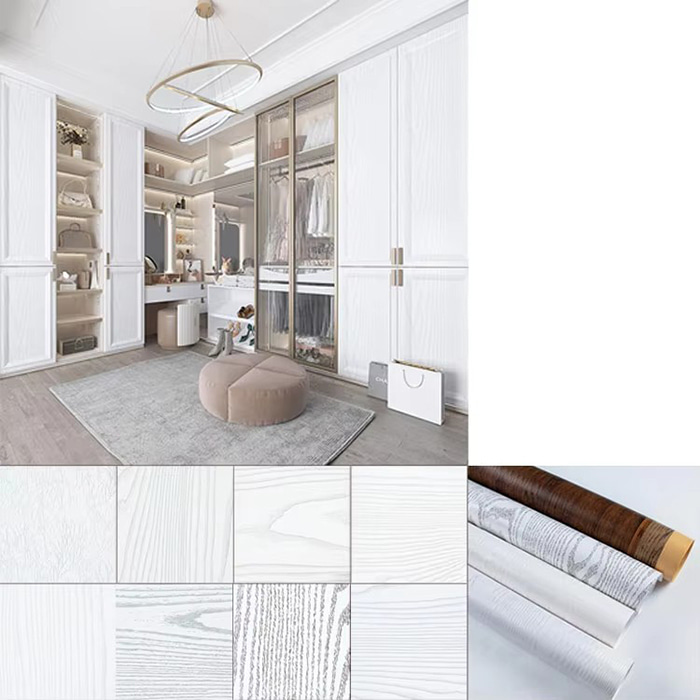

Furniture Industry

Panel furniture : Imitation wood grain and stone grain veneer (such as oak, walnut, marble texture) to enhance product added value.

Custom Home : Curved surface fitting (radius ≥ 10cm), suitable for special-shaped cabinets, door panels, and desktops.

Architectural DecorationInterior wall/ceiling : Waterproof and moisture-proof (water absorption ≤ 0.3%), directly adhered to the surface of cement and gypsum board.

Floor/Cabinet : The wear-resistant layer is scratch-resistant (≥5000 revolutions), suitable for high-humidity environments such as kitchens and bathrooms.

Cars and Transportation

Car interior : Instrument panel, door panel covering (high temperature resistant to 80℃), UV resistance (yellowing index ΔE≤1.5).

Ship/High-speed Rail : Fire protection grade B1 (UL94 V-0), salt spray corrosion resistance (500 hours without blistering).

ElectronicsHome appliance housing : Metal brushing and gradient effects enhance the aesthetics of products (such as air conditioning panels and small appliance housings).

3C accessories : Anti-scratch coating protects the screen and buttons (pencil hardness ≥ 2H).

Advertising displayLight Box/Display Stand : Light transmittance ≥85%, built-in LED light source to achieve three-dimensional luminous effect.

Signage: Reflective coating (retroreflection coefficient ≥ 500cd/lx/m²), suitable for outdoor advertising.

High-precision pattern restoration1200dpi printing resolution, texture clarity reaches micron level, supports photo-level effect image transfer.

Super wear-resistant and weather-resistant The surface wear-resistant layer has a rotation life of ≥5000 and a weather resistance of Grade 5 (no powdering after 500 hours of QUV aging test).

Environmental safety No formaldehyde, no heavy metals, complies with EN71-3 children's toy safety standards, and is recyclable and degradable.

Diversified Design Supports more than 1,000 patterns including wood grain, stone grain, brushed metal, gradient, etc., and can customize dynamic grating effects.

Convenient construction Comes with self-adhesive or cold-stick installation, no glue required, adaptable to curved surfaces and special-shaped substrates (minimum radius 10cm).

Cost-effective The cost is only 1/3 of that of solid wood veneer, and the service life is over 5 years (traffic ≥ 3000 times/day).

Versatility Antistatic treatment (surface resistance ≤1×10⁶Ω), antibacterial (nano silver ion coating, antibacterial rate ≥ 99%).

Substrate treatment

PVC film preparation : Polyvinyl chloride resin (S-70) + plasticizer (DOP) + stabilizer (Ca-Zn), formed by calendering process, thickness error ≤±0.02mm.

Printing Technology

Four-color gravure printing :Ink adhesion reaches 4B level (ASTM D3359), color difference ΔE≤0.5.

Laser Engraving:CO₂ Laser engraving machine (power ≥ 100W), minimum line width 0.01mm, depth 0.05mm.

Transfer process

Vacuum transfer : High temperature (180-220℃) and high pressure (≥0.8MPa) transfer, pattern transfer rate ≥99%.

UV Curing :UV coating film thickness ≥15μm, curing energy ≥800mJ/cm², hardness ≥3H.Post-processing technologySurface hydrophobic treatment : Nano-silica coating, contact angle ≥110°, waterproof and anti-fouling.

Anti-scratch treatment Diamond-like carbon (DLC) coating, pencil hardness ≥ 4H.

Quality Inspection

Wear test : Taber has no exposed bottom after 5000 turns (CS-10 wheel, load 1kg).

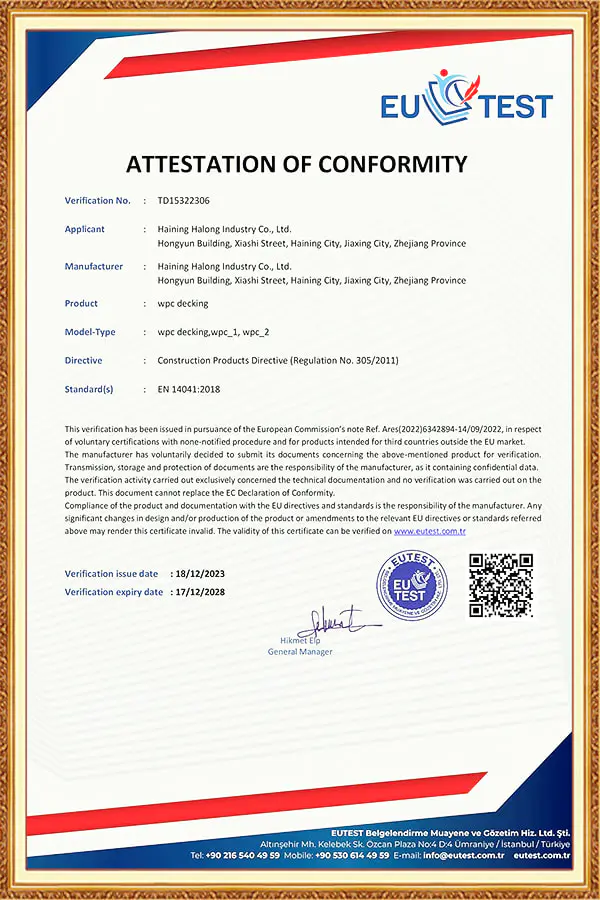

Environmental certification : Certified by SGS, Intertek and CARB.

Special Process

Metal Texture : Vacuum electroplated aluminum layer (thickness ≥ 2μm), reflectivity ≥ 85%.

3D relief : Electric carving mold pressing (depth 0.1-0.3mm), real touch.

Established in 2005, our factory started with producing PVC Ceiling and Wall Panels, and has grown to be a professional China PVC ceiling panels manufacturer and a wholesale PVC panels factory, committed to providing our customers with high-quality products and services. After 20 years of development, we now own 5 large factories: Haining Halong PVC Ceiling Factory, Haining Longtime Film Factory, Guangxi PVC Wall Panel Factory, Indonesia PVC Wall Panel Factory, and Vietnam PVC Wall Panel Factory.

Our main products include: PVC Ceiling Panels, PVC Wall Panels, WPC Wall Panels, Hot Stamping Foil, PVC Lamination Film, SPC Flooring, WPC Decking, and other related products. Our annual sales can reach up to 35 million USD.

Industry Background and Application Importance Decorative surface materials play a critical role in modern construction, interior systems, and modular building solutions. Tradition...

View MoreIndustry Background and Application Significance In modern construction, the choice of materials significantly impacts the durability, performance, and maintenance costs of a build...

View MoreRemoving PVC Self-Adhesive Wall Sticker from glass surfaces can be a challenging task if not approached correctly. The process requires understanding the adhesive properties, the t...

View MoreThe flooring industry has witnessed significant advancements in recent years, with new materials offering improved durability, aesthetics, and ease of installation. Among these inn...

View More