Specifications: 300mm×300mm, 600mm×600mm, 1200mm×600mm, etc.

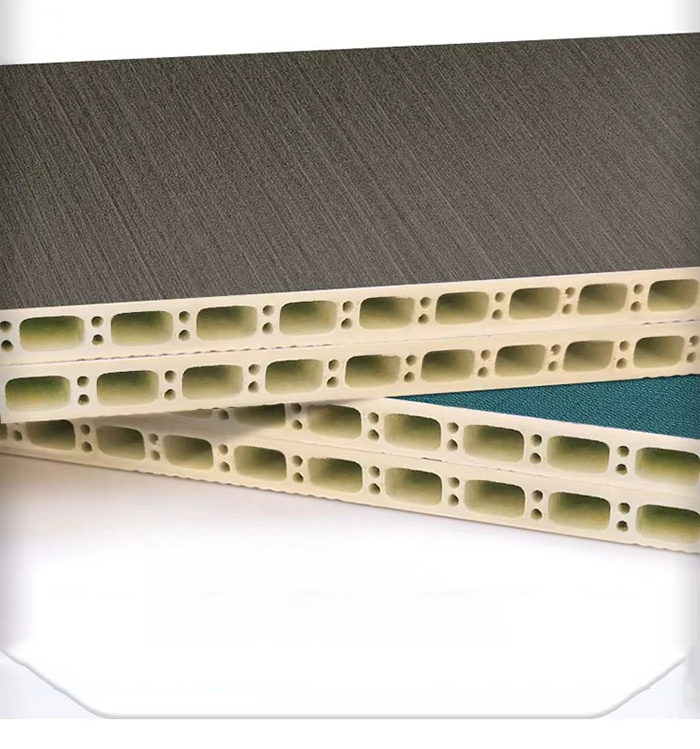

Thickness: 7mm, 8mm, 9mm Strength: Breaking load > 150N

Moisture content <1%

Allowable size difference: Length ≤±2.0mm; Width ≤±2.0mm;

Thickness ≤±0.5mm Weight <6.5kg/m²

Fire rating: B1, in accordance with GB8624-1997

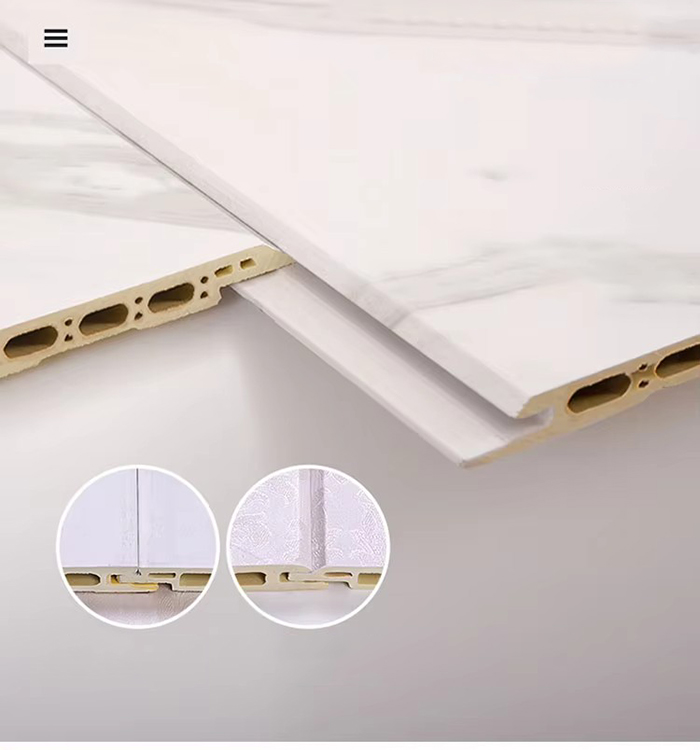

PVC ceiling is a lightweight building decoration material made of polyvinyl chloride as the main raw material through extrusion, molding or lamination. It is waterproof and moisture-proof, easy to clean, easy to install, and affordable, making it an important substitute for traditional gypsum boards and metal gussets. PVC ceiling products are rich in variety, covering a variety of styles such as flat panels, strip panels, hollow carved panels, etc., and are constantly innovating in color, texture, glossiness, etc. to meet the needs of diverse decoration styles.

Application scenarios and scope of application

Residential space: suitable for living room, bedroom, kitchen, bathroom, corridor, etc., especially suitable for high humidity areas such as kitchen and bathroom.

Commercial space: can be used for interior decoration of offices, shops, cafes, restaurants, bars and other places.

Public buildings: such as hospitals, schools, libraries and other public buildings indoor ceiling decoration, meet the requirements of fire prevention and moisture resistance.

Product Features/Advantages

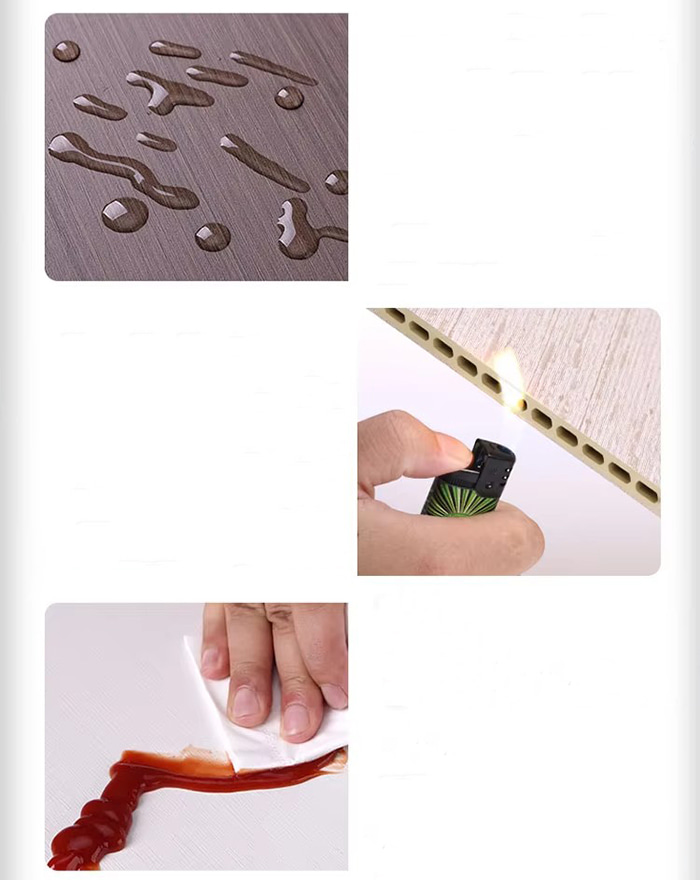

Waterproof and moisture-proof: It has good waterproof and moisture-proof properties and is suitable for humid environments.

Fireproof and flame retardant: The fireproof grade reaches B1, which is a flame-retardant material and can effectively prevent the spread of fire.

Wear-resistant and scratch-resistant: The surface is wear-resistant and can withstand daily friction and wear, keeping it beautiful and durable.

Sound insulation and heat insulation: It has certain sound insulation and heat insulation properties, which can reduce external noise and reduce indoor heat loss.

Environmental protection and health: It does not contain toxic substances such as asbestos, methanol, ammonia, etc., is harmless to food and human body, and meets environmental protection standards.

Easy to install: It is light in weight and can be sawed, planed, nailed, and drilled. There are various installation methods, saving time and cost. Easy to clean and maintain: The surface is smooth, not easy to be stained with dirt, and it is easy to clean. Just wipe it with a damp cloth.

Beautiful and diverse: The surface texture and color are rich, and it can present the appearance of a variety of natural materials to meet different decoration needs.

Technology and process

Ratio and mixing of raw materials: accurately proportion polyvinyl chloride resin, plasticizer, stabilizer and other raw materials, and fully mix them through a high-speed mixer to ensure uniform distribution of raw materials.

Extrusion molding: after the mixed raw materials are heated and melted by an extruder, they are extruded through a mold to form a PVC substrate with a certain thickness and width. Parameters such as temperature, pressure and speed are strictly controlled during the extrusion process.

Cooling and shaping: the extruded substrate needs to be cooled by a cooling and shaping device to make it solidify quickly and maintain a stable shape and size. The cooling method usually adopts air cooling or water cooling.

Surface treatment: the surface treatment of the substrate after cooling and shaping is carried out. Common treatment methods include lamination, printing, etc. Lamination can enhance the wear resistance and waterproofness of the ceiling, and printing can give the ceiling a variety of different patterns and textures.

Quality inspection: during the production process, the PVC ceiling is strictly inspected for quality, including dimensional accuracy, flatness, density, fire resistance, environmental protection performance and other aspects to ensure that the product meets relevant standards and quality requirements.

Established in 2005, our factory started with producing PVC Ceiling and Wall Panels, and has grown to be a professional China PVC ceiling panels manufacturer and a wholesale PVC panels factory, committed to providing our customers with high-quality products and services. After 20 years of development, we now own 5 large factories: Haining Halong PVC Ceiling Factory, Haining Longtime Film Factory, Guangxi PVC Wall Panel Factory, Indonesia PVC Wall Panel Factory, and Vietnam PVC Wall Panel Factory.

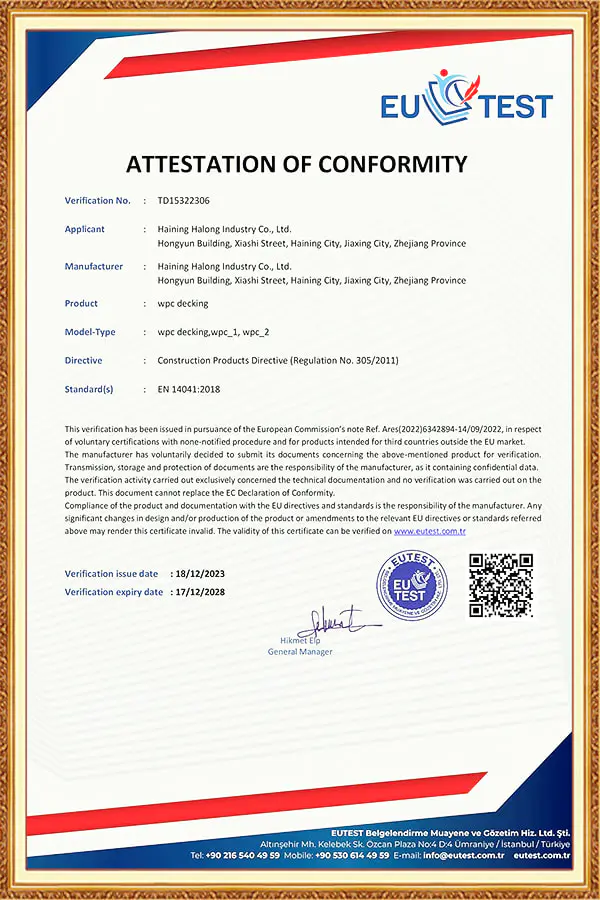

Our main products include: PVC Ceiling Panels, PVC Wall Panels, WPC Wall Panels, Hot Stamping Foil, PVC Lamination Film, SPC Flooring, WPC Decking, and other related products. Our annual sales can reach up to 35 million USD.

Industry Background and Application Importance In modern commercial and residential interior construction, wall panel systems are increasingly evaluated not only on aesthetics, but...

View MoreIndustry Background and Application Importance Decorative surface materials play a critical role in modern construction, interior systems, and modular building solutions. Tradition...

View MoreIndustry Background and Application Significance In modern construction, the choice of materials significantly impacts the durability, performance, and maintenance costs of a build...

View MoreRemoving PVC Self-Adhesive Wall Sticker from glass surfaces can be a challenging task if not approached correctly. The process requires understanding the adhesive properties, the t...

View More