Material: Polyvinyl chloride (PVC) Thickness: 0.035mm-0.12mm

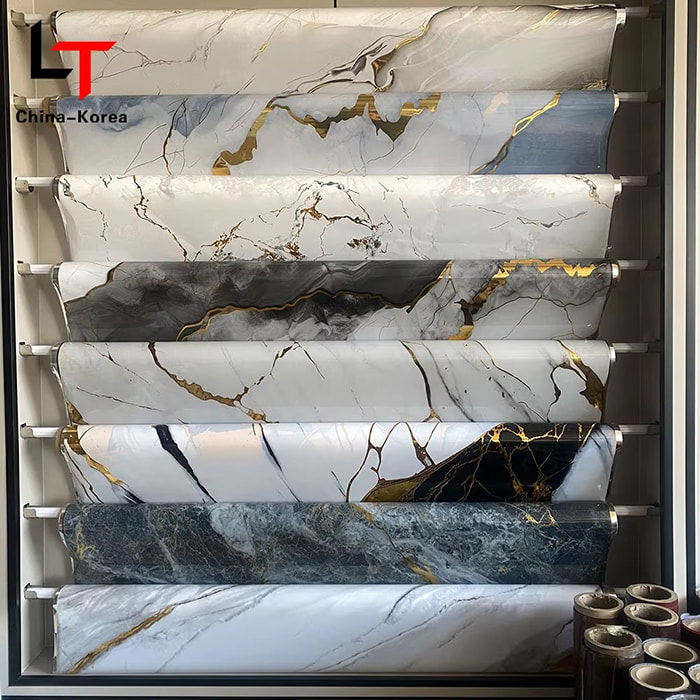

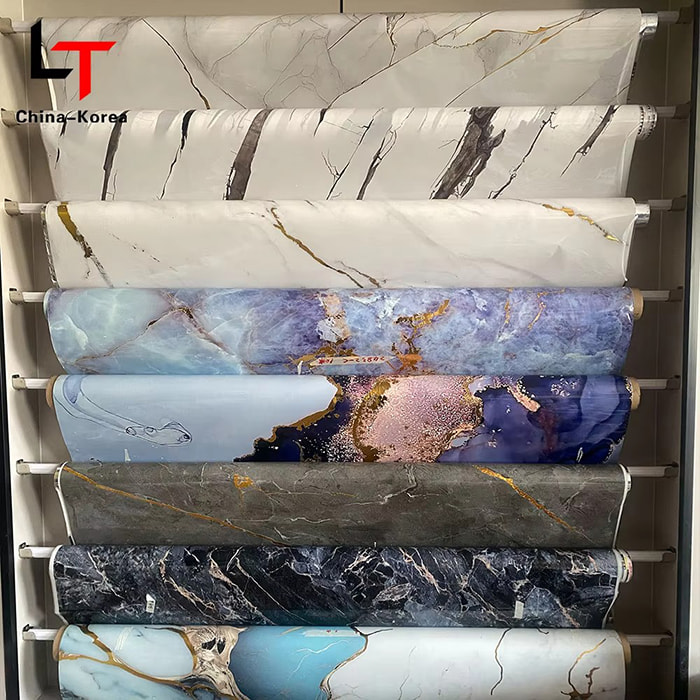

Width: 1000-2470mm Color: Transparent, purple, light blue, etc.

Surface treatment: Anti-ultraviolet, chemical corrosion resistant

Printing method: Screen printing

Features: Waterproof, fireproof, wear-resistant, scratch-resistant, stain-resistant, corrosion-resistant

Printed PVC film is a plastic film with polyvinyl chloride (PVC) as the main component. It has good wear resistance, scratch resistance, water resistance and oil resistance, and can resist the erosion of various chemical substances. It is widely used in packaging, building materials, medicine, electrical and other fields. The surface gloss of PVC film is good, and the ink adhesion is better than PE and PP film. Generally, corona treatment is not required before printing. According to the amount of plasticizer, it can be divided into three types of films: soft, semi-soft and hard.

Packaging: used for packaging of food, beverages, daily necessities, etc., such as shrink film, label film, etc.

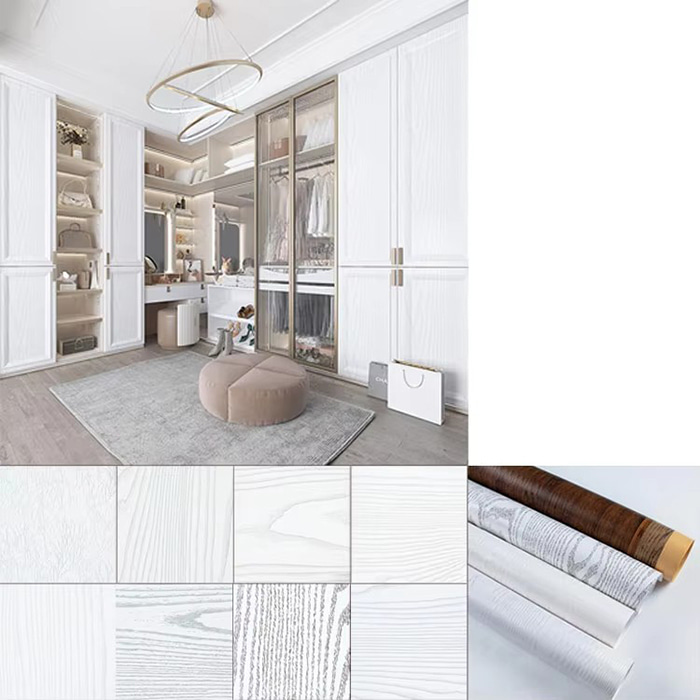

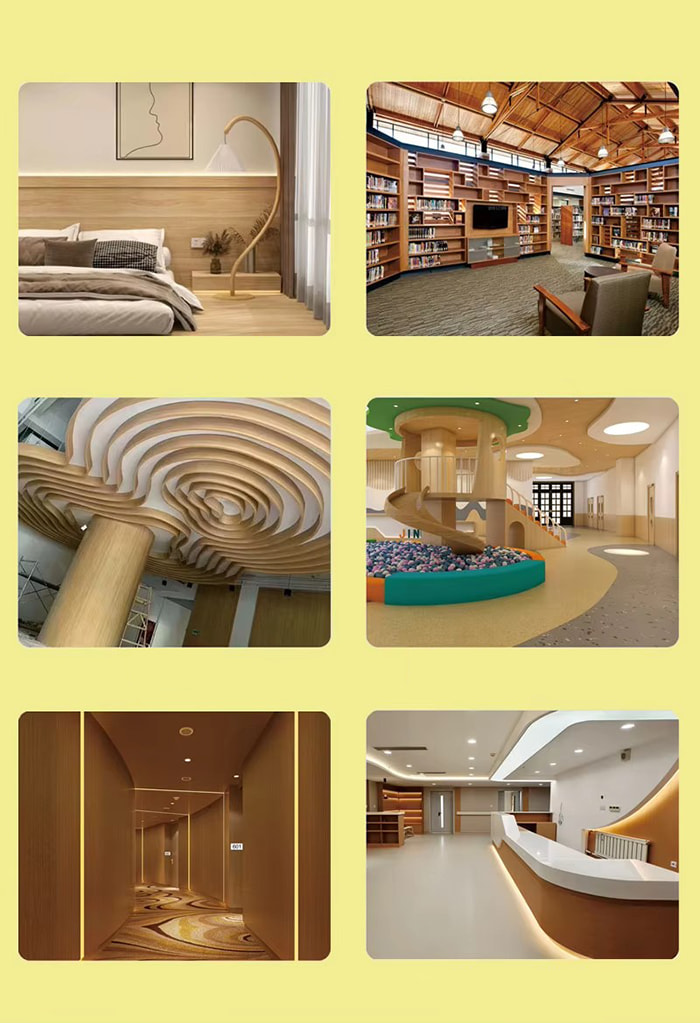

Building materials: used for doors, furniture, wardrobes, cabinets, interior wall decoration, ceiling decoration, etc.

Medicine: used for medicinal PVC boards, with functions such as heat insulation, moisture resistance, heat preservation, and anti-static.

Electrical: used for insulation protection of electrical equipment.

Advertising: used for making billboards, promotional posters, etc.

Performance advantages:

Chemical resistance: Resistant to oil, salt solution and water.

High impact resistance: It has high impact strength.

Flame retardant: It is not flammable and suitable for applications that require fire protection.

Printing advantages: High precision: Combined with screen printing technology, the printed products have reached a high level in color, clarity, durability, etc.

Diverse patterns: A variety of patterns can be printed, eight colors, beautiful and high-end.

Cost advantages: Affordable price: PVC film has high output and affordable price.

Reusable: Unused materials can be recycled and reused.

Production process: PVC film is manufactured through an extrusion molding process, where the granular raw materials are melted at high temperature and then formed by a press.

Printing process: Screen printing is an important technology in the application of PVC film. Through high-precision visual recognition and positioning technology, the pattern is accurately matched with the position of the PVC film surface to ensure that every printing is accurate.

Post-processing: After printing, PVC film products can be surface treated by sandpaper polishing, chemical treatment, etc. to improve their appearance and performance.

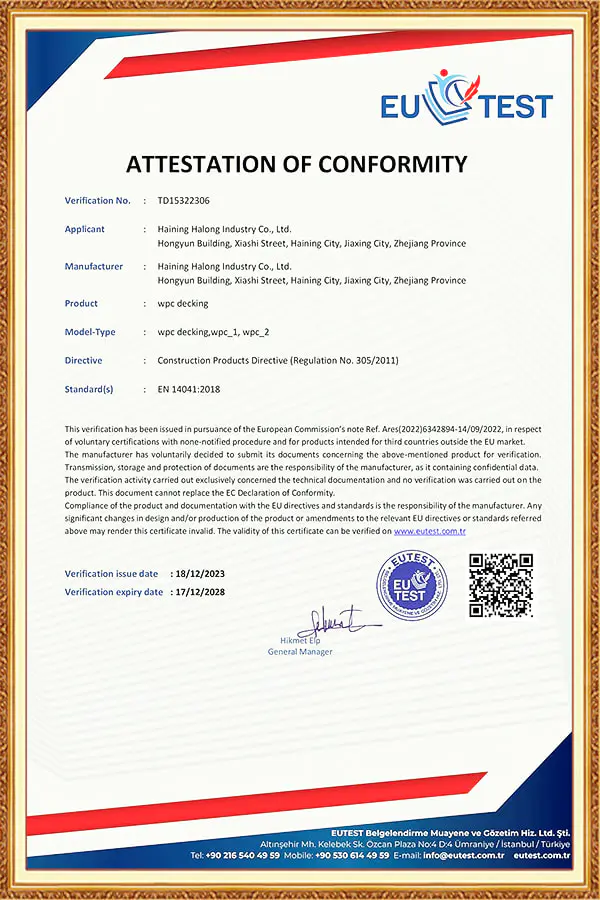

Established in 2005, our factory started with producing PVC Ceiling and Wall Panels, and has grown to be a professional China PVC ceiling panels manufacturer and a wholesale PVC panels factory, committed to providing our customers with high-quality products and services. After 20 years of development, we now own 5 large factories: Haining Halong PVC Ceiling Factory, Haining Longtime Film Factory, Guangxi PVC Wall Panel Factory, Indonesia PVC Wall Panel Factory, and Vietnam PVC Wall Panel Factory.

Our main products include: PVC Ceiling Panels, PVC Wall Panels, WPC Wall Panels, Hot Stamping Foil, PVC Lamination Film, SPC Flooring, WPC Decking, and other related products. Our annual sales can reach up to 35 million USD.

Industry Background and Application Importance Decorative surface materials play a critical role in modern construction, interior systems, and modular building solutions. Tradition...

View MoreIndustry Background and Application Significance In modern construction, the choice of materials significantly impacts the durability, performance, and maintenance costs of a build...

View MoreRemoving PVC Self-Adhesive Wall Sticker from glass surfaces can be a challenging task if not approached correctly. The process requires understanding the adhesive properties, the t...

View MoreThe flooring industry has witnessed significant advancements in recent years, with new materials offering improved durability, aesthetics, and ease of installation. Among these inn...

View More