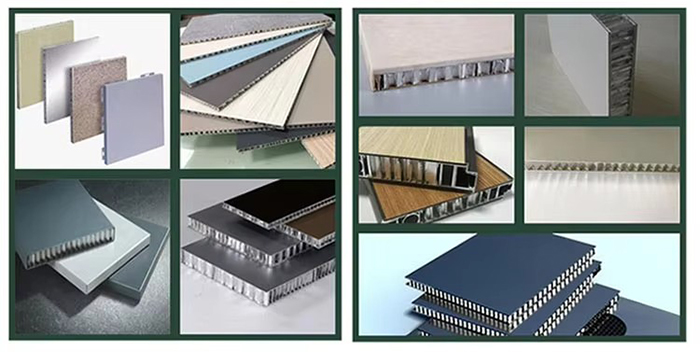

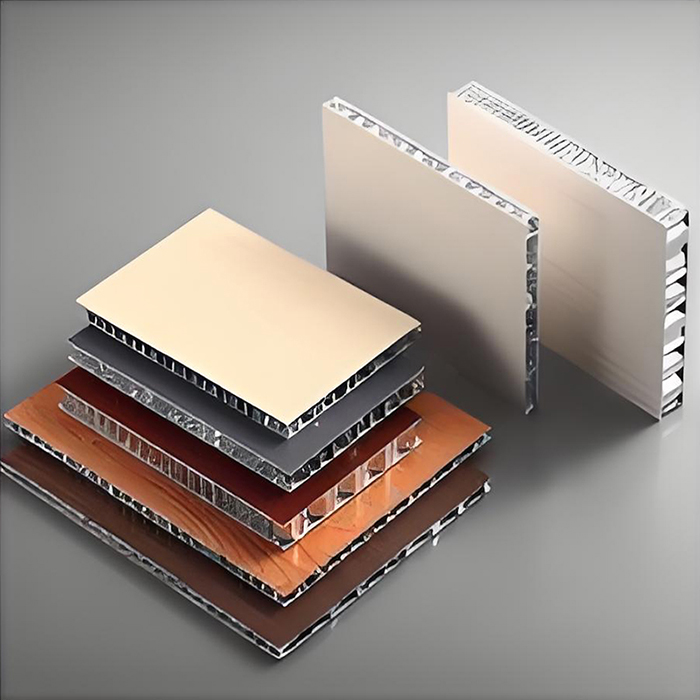

Panel material: high-quality 3003H24 alloy aluminum plate or 5052AH14 high manganese alloy aluminum plate

Panel thickness: 0.8~1.5mm Bottom plate thickness: 0.6~1.0mm

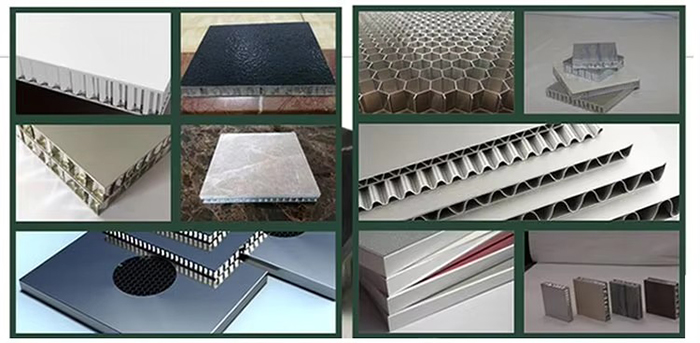

Honeycomb core material: 3003 aluminum foil, thickness: 0.04~0.06mm

Honeycomb core side length: 5~6mm

Total thickness: 5mm to 200mm

Width: 1000mm to 2000mm

Length can be customized to 12m or even longer

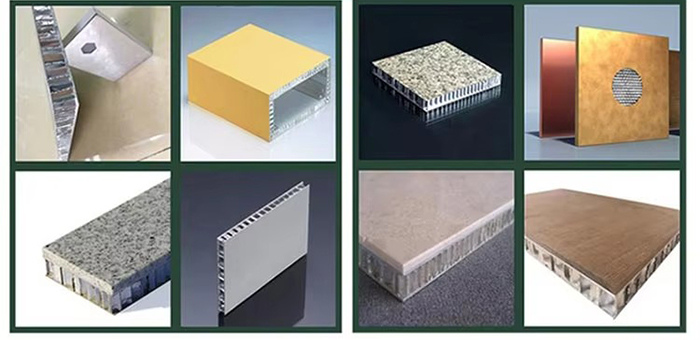

Surface treatment: fluorocarbon roller coating, anodizing

Aluminum honeycomb wall panel is a sandwich structure, consisting of two layers of aluminum and a honeycomb core. The panel is mainly made of high-quality 3003H24 alloy aluminum plate or 5052AH14 high manganese alloy aluminum plate as the base material, with a panel thickness of 0.8~1.5mm and a bottom plate thickness of 0.6~1.0mm. The honeycomb core is made of very thin 3003 aluminum foil with a thickness of 0.04~0.06mm and a side length of 5~6mm. It has a hexagonal honeycomb hole structure with holes connected to each other. The entire processing process is completed in a modern factory using hot pressing technology.

Building field: Building curtain wall: Suitable for high-rise buildings, commercial centers, airports and other occasions. Its light weight, high strength, good sound insulation and heat insulation properties make aluminum honeycomb panels an ideal choice for modern building curtain walls.

Ceiling: In building decoration, aluminum honeycomb panels are also commonly used for ceilings. Its high tensile strength characteristics can reduce the need for ceiling structure reinforcement, while ensuring the flatness and smoothness of the ceiling, showing a good decorative effect.

Building roof: Aluminum honeycomb panels can also be used for building roofs, providing a variety of panel materials, shapes, colors and finishes to meet different design needs.

Partition walls: In indoor spaces, aluminum honeycomb panels can be used as partition walls, which are both decorative and have good sound insulation and heat insulation properties.

Furniture manufacturing: Aluminum honeycomb panels are also widely used in the field of furniture manufacturing, such as wardrobe doors, cabinet doors, TV background walls, etc. Its advantages such as light weight, high strength and corrosion resistance can extend the service life of furniture and improve the overall quality of furniture.

Transportation: Aluminum honeycomb panels are also widely used in transportation, including the siding of van trucks, doors and compartment panels of subways and high-speed trains. Its lightweight properties help reduce the vehicle's weight and improve fuel efficiency; at the same time, good sound insulation and heat insulation properties also improve passenger comfort.

Other fields: Elevator decoration: Aluminum honeycomb panels can be used in the walls, floors, ceilings and other parts of elevator cars, providing beautiful and practical decorative effects.

Industrial machinery: In the field of industrial machinery, aluminum honeycomb panels can be used as anti-vibration tables, automatic drawing boards and other components to meet specific functional requirements.

Product features/advantages

Lightweight and high strength: low density and light weight, which is 1/5 of the weight of wood boards of the same thickness and area, 1/6 of glass, and 1/7 of aluminum, greatly reducing the building load and cost. At the same time, it has high strength and rigidity, can withstand high-intensity pressure and shear force, and is not easy to deform. Heat insulation and sound insulation: Because the middle interlayer contains a lot of air, it can be soundproof (air sound insulation can reach 30dB), heat insulation (thermal resistance can reach 0.02(㎡·K/W)).

Fireproof and environmentally friendly: Aluminum plate is a non-combustible material. Honeycomb panels are pure aluminum products, do not volatilize any harmful gases to the human body, are non-radioactive and can be completely recycled, and are 100% environmentally friendly products.

Good weather resistance: The surface has excellent weather resistance after being treated with fluorocarbon resin with strong corrosion resistance. Following nature, product innovation often imitates the structure and form of nature. Human inventions and creations are all inspired by nature and adapt to the requirements of nature.

High flatness: The surface has extremely high flatness, and even if the grid size of the honeycomb panel is large, it can achieve extremely high flatness.

Easy to install: It is installed on both sides without mechanical damage. The sliding mounting buckle system allows thermal expansion and contraction, and the anti-slip buckle at the bottom of the board will control the expansion direction of the board.

Technology and Process

Rolling Forming Technology: In the process of making the panel and back panel, ten rollers are used to gradually fold the edge of the panel to the preset angle. The gradual forming ensures the release of internal stress and minimizes the damage to the metal itself.

Continuous Pre-Rolling Technology: The coating color is attached to the aluminum coil when it is formed. The coating has strong adhesion, good durability, uniform color, and basically no color difference in the same batch of products.

Honeycomb Composite Technology: Derived from the scientific and technological achievements of modern aviation, it uses high-temperature composite and panel hot pressing technology to ensure the integrity, strength and flatness of the panel.

Adhesive Selection: Aluminum honeycomb panels produced by continuous composite process of polyurethane, epoxy resin reactive curing adhesive or thermoplastic film.

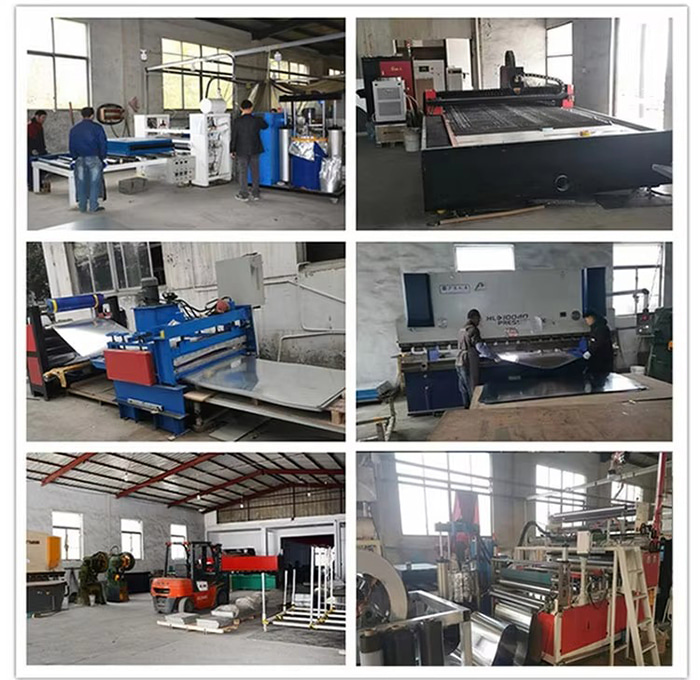

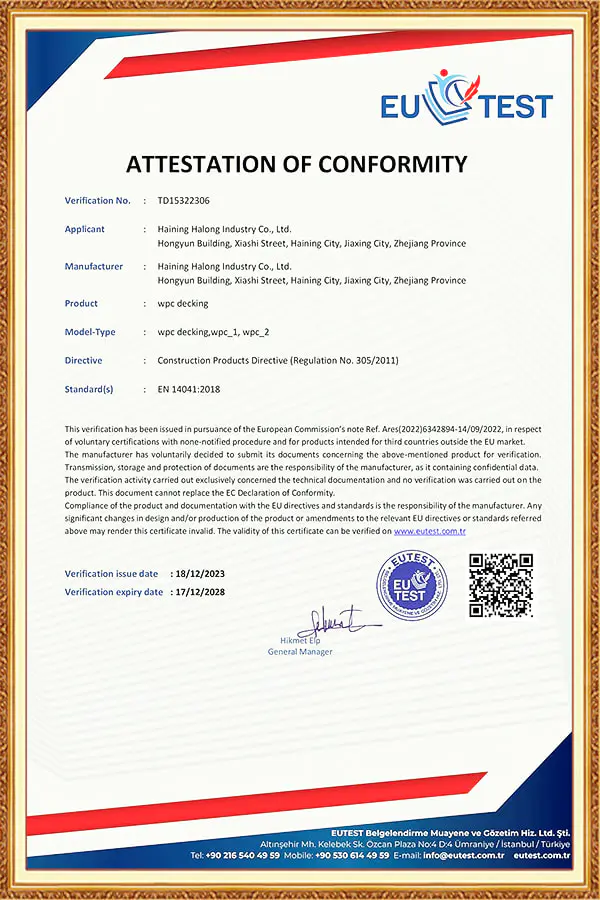

Established in 2005, our factory started with producing PVC Ceiling and Wall Panels, and has grown to be a professional China PVC ceiling panels manufacturer and a wholesale PVC panels factory, committed to providing our customers with high-quality products and services. After 20 years of development, we now own 5 large factories: Haining Halong PVC Ceiling Factory, Haining Longtime Film Factory, Guangxi PVC Wall Panel Factory, Indonesia PVC Wall Panel Factory, and Vietnam PVC Wall Panel Factory.

Our main products include: PVC Ceiling Panels, PVC Wall Panels, WPC Wall Panels, Hot Stamping Foil, PVC Lamination Film, SPC Flooring, WPC Decking, and other related products. Our annual sales can reach up to 35 million USD.

Industry Background and Application Importance In modern commercial and residential interior construction, wall panel systems are increasingly evaluated not only on aesthetics, but...

View MoreIndustry Background and Application Importance Decorative surface materials play a critical role in modern construction, interior systems, and modular building solutions. Tradition...

View MoreIndustry Background and Application Significance In modern construction, the choice of materials significantly impacts the durability, performance, and maintenance costs of a build...

View MoreRemoving PVC Self-Adhesive Wall Sticker from glass surfaces can be a challenging task if not approached correctly. The process requires understanding the adhesive properties, the t...

View More