Material Polyvinyl chloride (PVC resin) + wood fiber/bamboo fiber + calcium carbonate powder + anti-ultraviolet additives

Size

Standard specifications: height 1.8m-2.5m, length 2.44m/3m (support customized height ≤3m, length ≤6m)

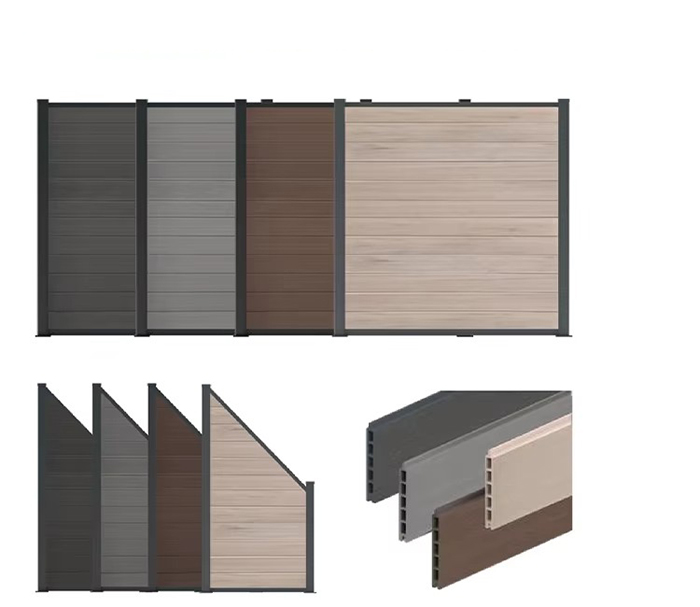

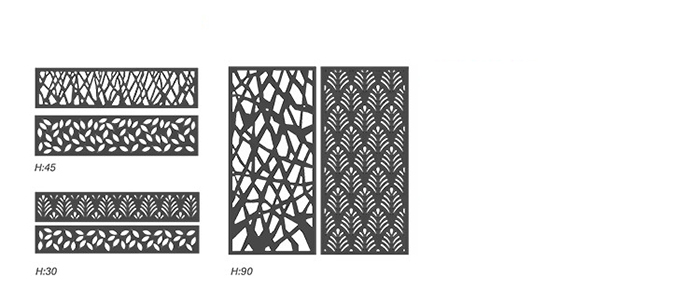

Board width 100mm-300mm (imitation wood grain/stone grain panel)

thickness 30mm-50mm (including frame structure)

Bending strength ≥80MPa (GB/T 6892 standard)

Impact resistance ≥10kJ/m² (GB/T 1043.1 standard)

Fire rating B1 flame retardant (GB 8624 standard)

Moisture resistance

Water absorption expansion rate ≤ 0.5% (GB/T 17657 standard, 24-hour water immersion test)

Weather resistance Ultraviolet accelerated aging test ≥5000 hours (ΔE≤5.0)

Environmental standards Compliant with RoHS, EN 717-1 (formaldehyde ≤ 0.05mg/m³), CARB certification

Density 1.8-2.5g/cm³ (composite structure of wood powder and PVC)

Weight About 45kg/m² (taking a height of 2m and a thickness of 30mm as an example, which is 1/3 of the galvanized steel fence)

Temperature resistance-40℃ to 70℃ (no deformation during long-term use)

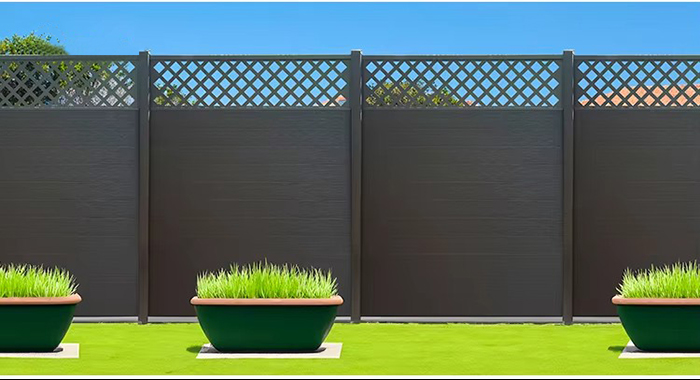

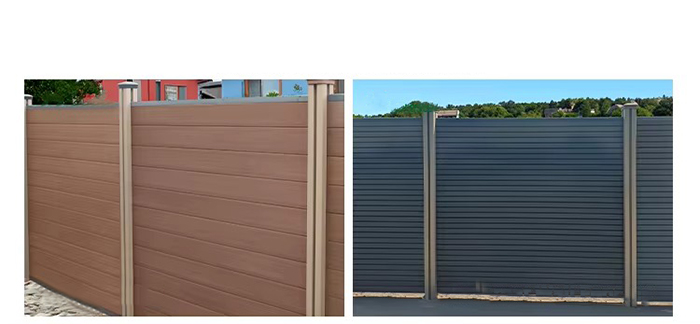

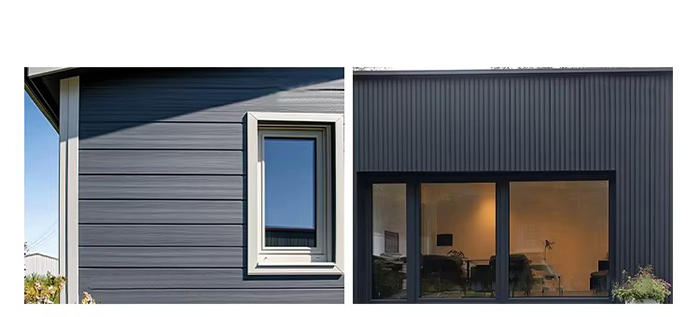

WPC fence is an outdoor protective material made of wood fiber or bamboo fiber as the core raw material, compounded with PVC resin, calcium carbonate powder and anti-ultraviolet additives through high temperature and high pressure process. The surface adopts imitation wood grain, stone grain or solid color coating, which combines the texture of natural wood with the corrosion resistance of plastic, and has the characteristics of waterproof and moisture-proof, mildew-proof and antibacterial, light weight and high strength. It is suitable for scenes such as residential courtyards, garden landscapes, highway isolation, etc., and is an environmentally friendly upgraded alternative to traditional wooden fences and metal fences.

Residential scene

Courtyard/Garden : The imitation wood grain appearance is natural and beautiful, and no regular painting maintenance is required.

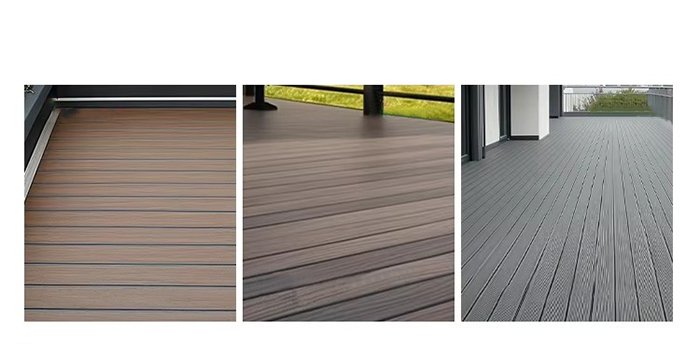

Balcony/terrace : Anti-slip surface (friction coefficient ≥ 0.6), suitable for humid environments.

Commercial and public facilitiesScenic spots/parks : Modular splicing design supports quick installation and scene switching.

Highway/Divider Strong impact resistance (impact resistance ≥ 10kJ/m²), excellent weather resistance.

Special Environment

Coastal Areas : Salt spray corrosion resistance (salt spray test ≥ 1000 hours), anti-rust.

High-altitude areas: Resistant to low temperature cracking (no brittleness at -40℃), suitable for the severe cold climate in the north.

Natural Aesthetics

It supports 10+ surface effects including imitation wood grain, stone grain, solid color, etc., with a texture clarity of up to 1200dpi, comparable to natural materials.

Superior performance

Fireproof B1 (flame spread time ≥ 30 minutes), anti-ultraviolet aging (ΔE ≤ 5.0), service life ≥ 15 years.

Impact resistance is twice that of ordinary PVC fence (≥ 10kJ/m²), bending strength ≥ 80MPa.

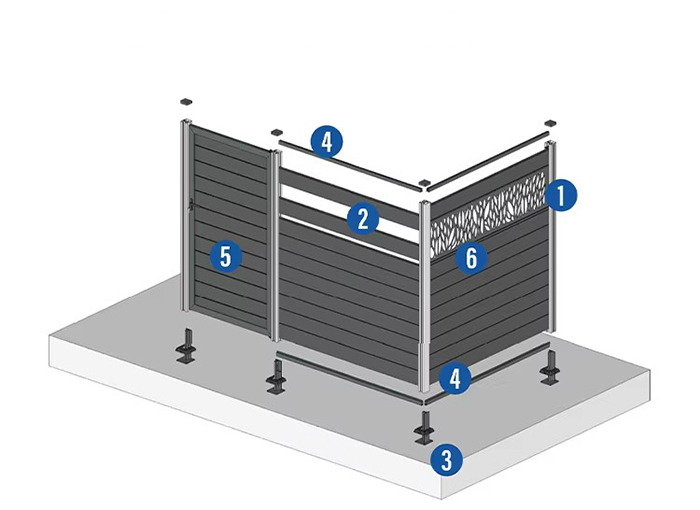

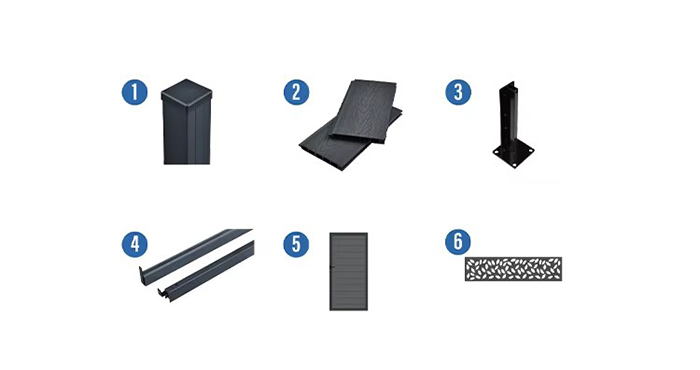

Easy installation

Snap-on/mortise and tenon installation (no welding required), modular assembly, shortening construction period by 60%.

Economic and environmental protection

The overall cost is lower than that of galvanized steel fencing (about 1/2 the price), the material is 100% recyclable, and there is no construction waste.

Low maintenance

No need to repaint, only need to rinse with water, and the maintenance cost is reduced by 80%.

Safety protection

Rounded corner anti-collision design (R angle ≥ 5mm), non-slip surface, suitable for children and elderly activity areas.

Raw material handling

Wood fiber modification :The wood powder is carbonized and dried (water content ≤ 8%) to enhance its compatibility with PVC.

Anti-aging formula : Add hindered amine light stabilizer (HALS) and UV absorber (UV-Absorber) to improve weather resistance.

Extrusion

Co-extrusion process : PVC substrate and wood fiber are co-extruded at 180℃-220℃, and the thickness error is ≤±0.3mm.

Imitation wood grain

Technology : Vacuum thermal transfer technology, texture clarity up to 1200dpi, adhesion ≥ level 1 (ASTM D3359).

Surface treatment

UV coating : Three-coat-one-bake process, film thickness ≥30μm, wear resistance up to 5000 revolutions (Taber test).

Hydrophobic coating : Nano-silica coating, contact angle ≥110°, waterproof and anti-fouling.

Quality Inspection

Fire test : GB 8624 standard, B1 flame retardant.

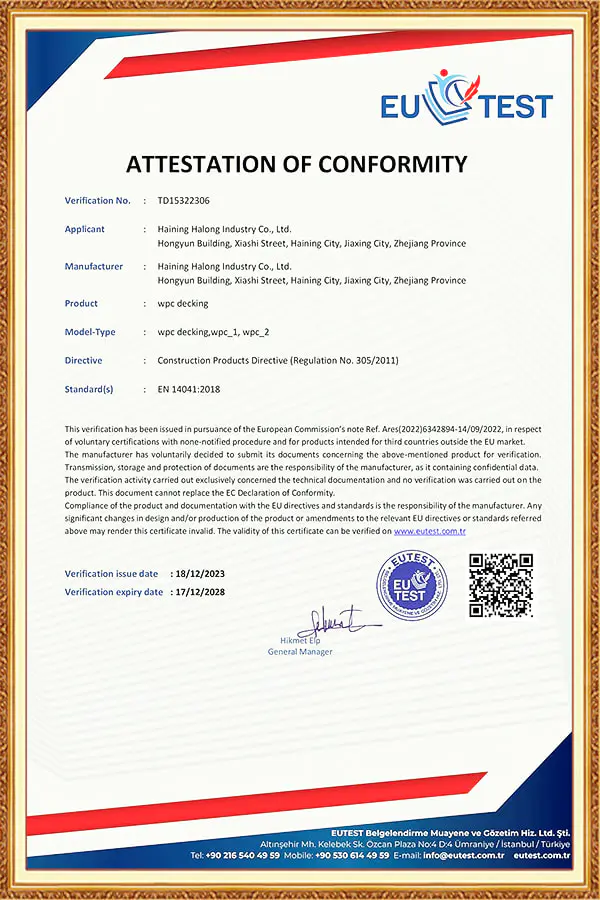

Environmental certification : Passed CARB certification, CE certification (EU), China Environmental Labeling (Ten-Ring Certification).

Special ProcessEdge sealing : Ultrasonic welding technology prevents moisture from penetrating and prolongs service life.

Lightning protection design:The metal frame is grounded (grounding resistance ≤ 4Ω), suitable for areas prone to lightning.

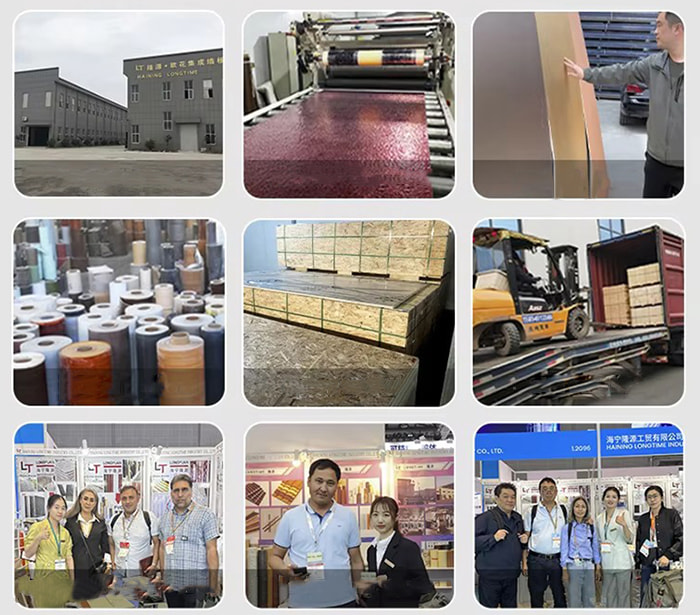

Established in 2005, our factory started with producing PVC Ceiling and Wall Panels, and has grown to be a professional China PVC ceiling panels manufacturer and a wholesale PVC panels factory, committed to providing our customers with high-quality products and services. After 20 years of development, we now own 5 large factories: Haining Halong PVC Ceiling Factory, Haining Longtime Film Factory, Guangxi PVC Wall Panel Factory, Indonesia PVC Wall Panel Factory, and Vietnam PVC Wall Panel Factory.

Our main products include: PVC Ceiling Panels, PVC Wall Panels, WPC Wall Panels, Hot Stamping Foil, PVC Lamination Film, SPC Flooring, WPC Decking, and other related products. Our annual sales can reach up to 35 million USD.

Industry Background and Application Importance In modern commercial and residential interior construction, wall panel systems are increasingly evaluated not only on aesthetics, but...

View MoreIndustry Background and Application Importance Decorative surface materials play a critical role in modern construction, interior systems, and modular building solutions. Tradition...

View MoreIndustry Background and Application Significance In modern construction, the choice of materials significantly impacts the durability, performance, and maintenance costs of a build...

View MoreRemoving PVC Self-Adhesive Wall Sticker from glass surfaces can be a challenging task if not approached correctly. The process requires understanding the adhesive properties, the t...

View More