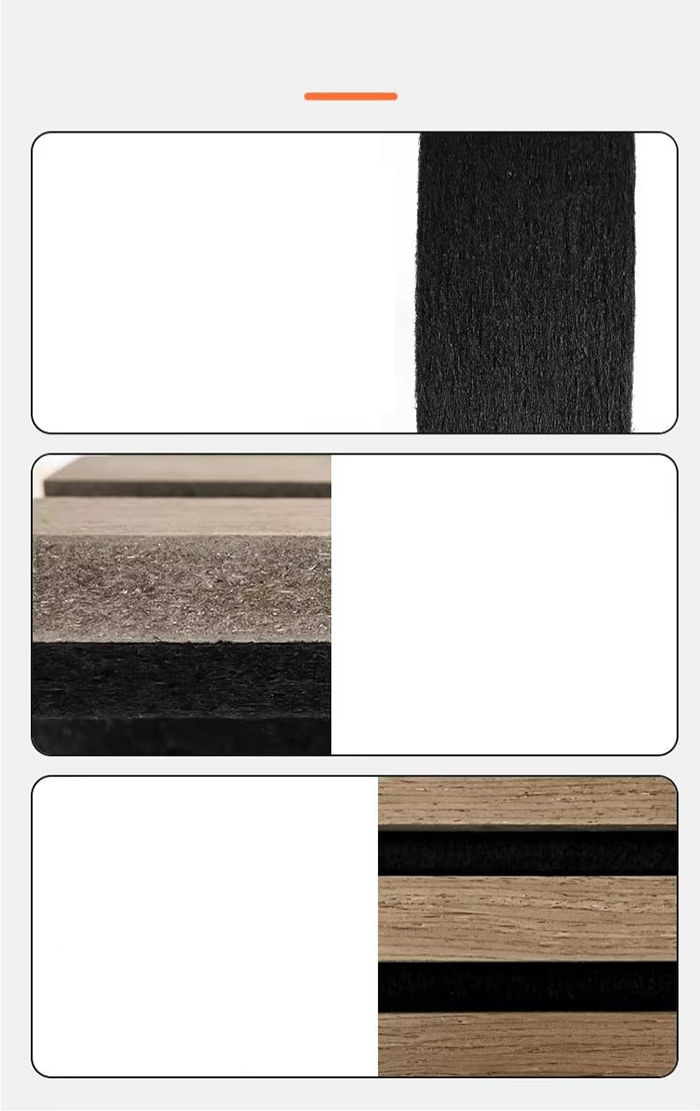

Material Polyvinyl chloride (PVC resin) + wood fiber/bamboo fiber + sound-absorbing cotton/porous structure + antistatic coating

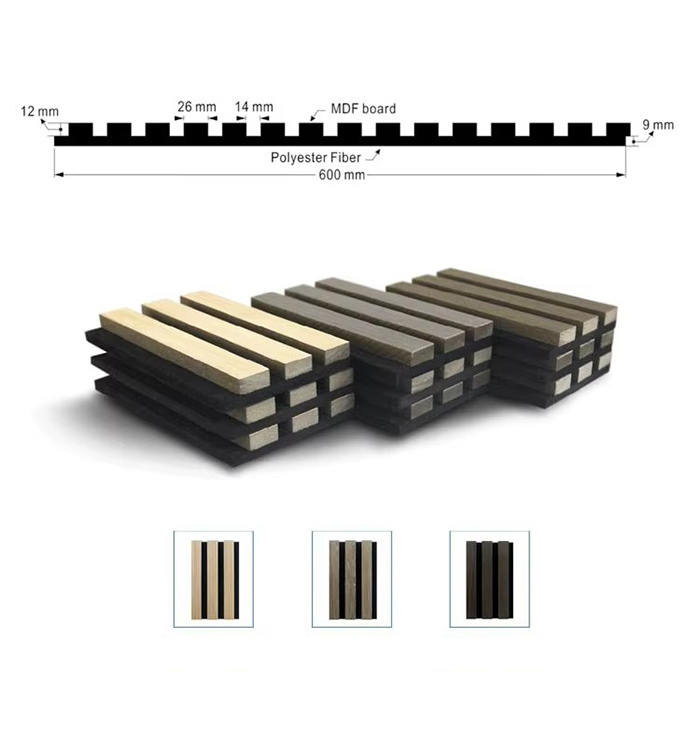

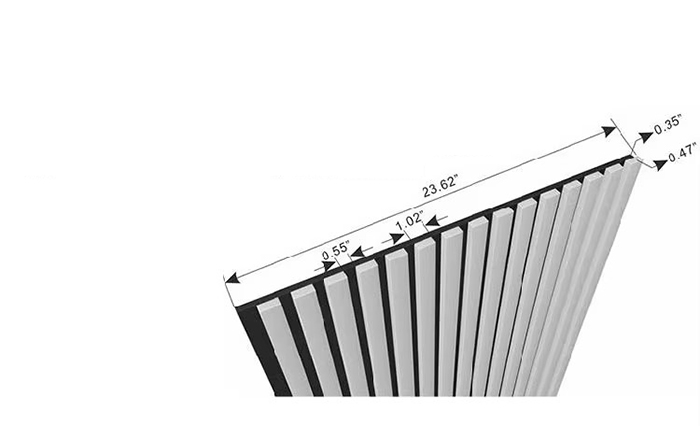

Size

Standard specifications: 1220mm×2440mm/1200mm×600mm (support customized width ≤1220mm, length ≤3m)

thickness 10mm-30mm (conventional thickness: 15mm, 18mm, 20mm)

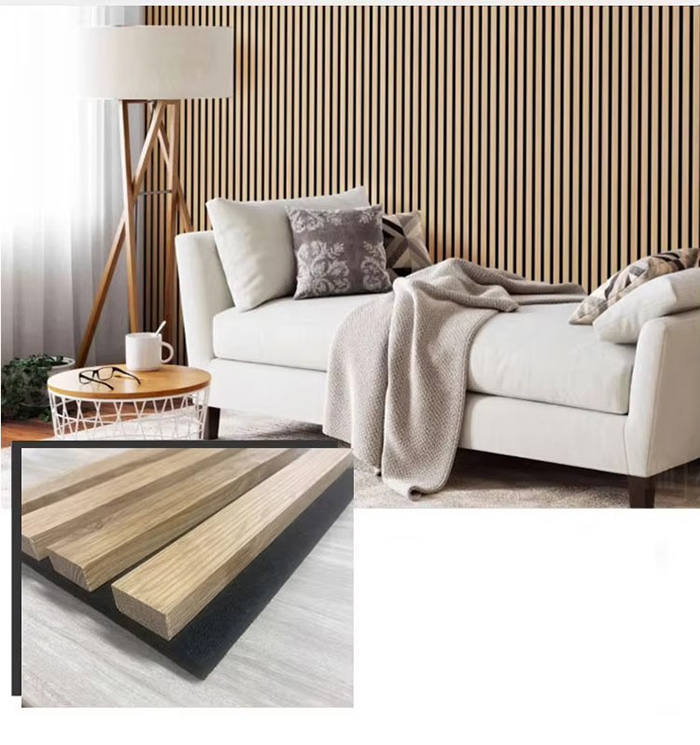

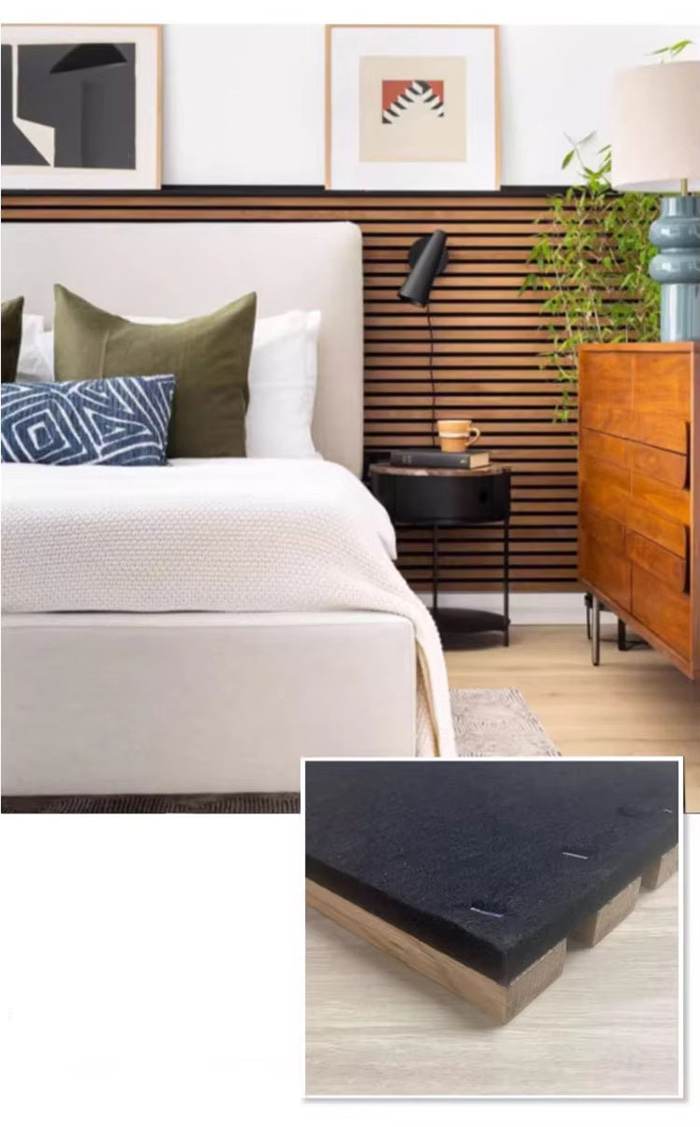

Surface treatment Grooved wood grain, honeycomb holes, wavy patterns, fabric textures (porous structures enhance sound absorption)

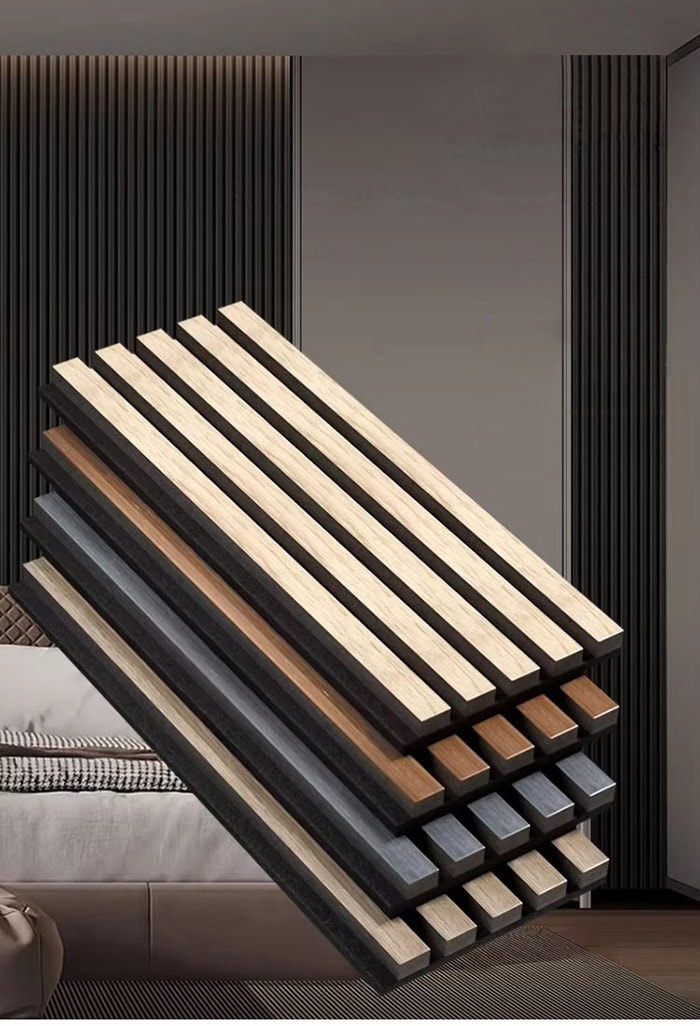

Color

Natural wood color, stone color, solid color (support Pantone color customization)

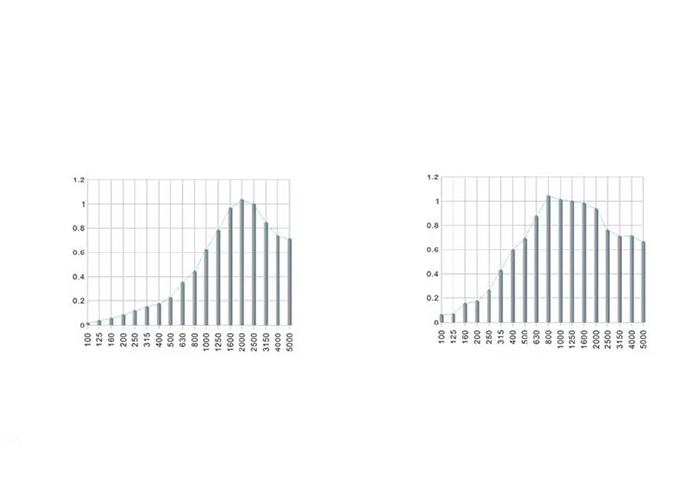

Noise Reduction Coefficient (NRC) ≥0.8 (GB/T 16731 standard)Sound insulation performance

Weighted sound insulation Rw ≥ 35dB (GB/T 19889 standard, 15mm thickness)

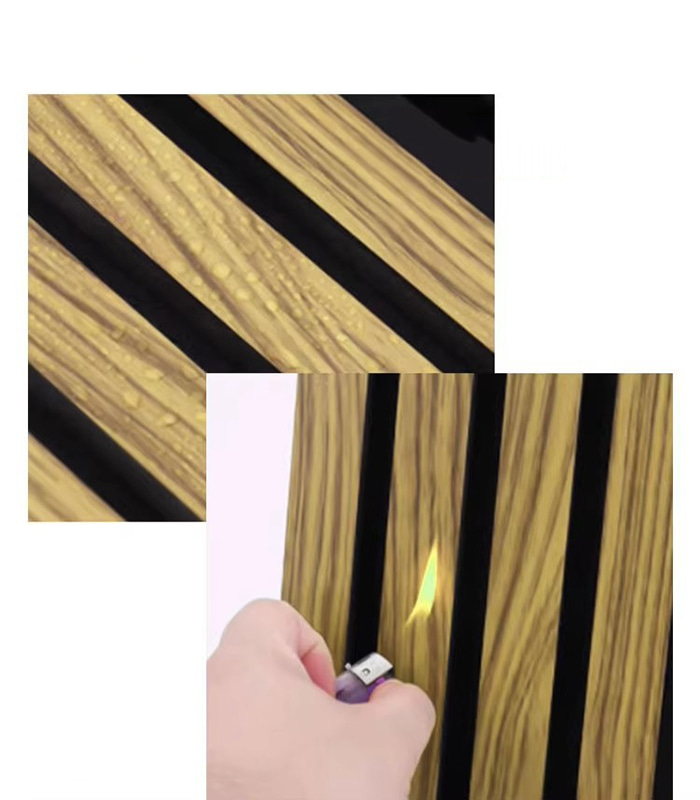

Fire rating B1 flame retardant (GB 8624 standard)

Environmental standards Compliant with RoHS, EN 717-1 (formaldehyde ≤ 0.05mg/m³), ASTM C423 acoustic certification

Density 2.0-2.8g/cm³ (porous structure + PVC reinforcement layer)

Weight About 3.5kg/m² (taking 15mm thickness as an example, which is 1/2 of traditional sound-absorbing cotton)

Temperature resistance-20℃ to 70℃ (no deformation during long-term use)

WPC sound-absorbing board is a composite functional board with wood fiber or bamboo fiber as the core sound-absorbing medium, combined with PVC resin, sound-absorbing cotton and antistatic coating. Through the high-density porous structure design (porosity ≥30%), it effectively absorbs medium and high-frequency sound waves (500Hz-4000Hz sound absorption rate ≥85%), and has moisture-proof, fire-proof and environmentally friendly characteristics. It is suitable for scenes with high acoustic requirements such as recording studios, theaters, and conference rooms. It is an upgraded substitute for traditional sound-absorbing cotton and mineral wool boards.

Professional acoustic venues

Recording Studio/Theater : Porous structure + honeycomb design reduces reverberation time (T60≤0.8s) and improves sound clarity.

Concert Hall/Cinema : Surface texture can adjust sound wave diffusion (diffusion coefficient ≥ 0.6) and optimize sound field distribution.

Commercial SpaceHotel/Restaurant : Sound absorption and noise reduction (NRC ≥ 0.8), reducing environmental noise interference (background noise ≤ 45dB).

Office/Meeting Room : Anti-echo design (Speech Transmission Index STI ≥ 0.65) to improve speech clarity.

Public Facilities

Stadium/Airport : Fire protection level B1 + sound absorption and noise reduction (weighted sound insulation Rw ≥ 35dB), in line with public safety standards.

School/Library : Antibacterial and mildew-proof (antibacterial rate ≥ 99%), suitable for high-traffic environments.

Family scene

Children's room/study room: Rounded corner anti-collision design + low formaldehyde emission (≤0.03mg/m³), safe and environmentally friendly.

Highly efficient sound absorption

Porous structure (porosity ≥ 30%) + honeycomb layer design, mid-high frequency sound absorption rate ≥ 85%, NRC ≥ 0.8.

Surface texture can adjust the sound wave reflection angle and reduce echo interference (language clarity improved by 30%).

Multifunctional integrationFireproof B1 (flame spread time ≥ 30 minutes) + moisture-proof (water absorption expansion rate ≤ 0.3%), adaptable to complex environments.

Antistatic coating (surface resistance ≤ 1×10⁶ Ω), reducing dust absorption.

Diversified Design It supports more than 10 surface effects including grooved wood grain, fabric texture, wavy grain, etc., taking into account both acoustic performance and decorativeness.

Easy installation Clip-on/keel installation (no glue required), modular assembly, shortening construction time by 70%.

Environmentally friendly and durable

The material is 100% recyclable, the surface wear resistance reaches 10,000 revolutions (Taber test), and the service life is ≥15 years.

Intelligent Adaptation Sensors or LED light strips can be integrated to achieve sound and light linkage (customized circuit required).

Sound-absorbing structure design

Porous layer : Wood fiber and sound-absorbing cotton are composited, with a porosity of ≥30% and a pore size distribution of 0.5-2mm to optimize sound wave absorption.

Damping layer Add rubber particles (particle size 1-3mm) to improve low-frequency noise absorption (100Hz-500Hz sound absorption rate ≥75%).

Material Composite Process

Co-extrusion : The PVC surface layer and the sound-absorbing core material are co-extruded at 180℃-220℃, and the thickness error is ≤±0.2mm.

Surface Grooving : Laser cutting process, groove depth 1-3mm, groove spacing 5mm, enhanced sound wave diffusion.

Surface treatment technology

Fabric Texture : Non-woven fabric lamination + hot pressing molding, air permeability increased by 20%, sound absorption efficiency increased by 15%.

Antistatic coating:Nano silicon dioxide coating, surface resistance ≤1×10⁶ Ω, dustproof and anti-static.

Quality InspectionAcoustic testing :ASTM C423 standard, NRC≥0.8, Rw≥35dB.

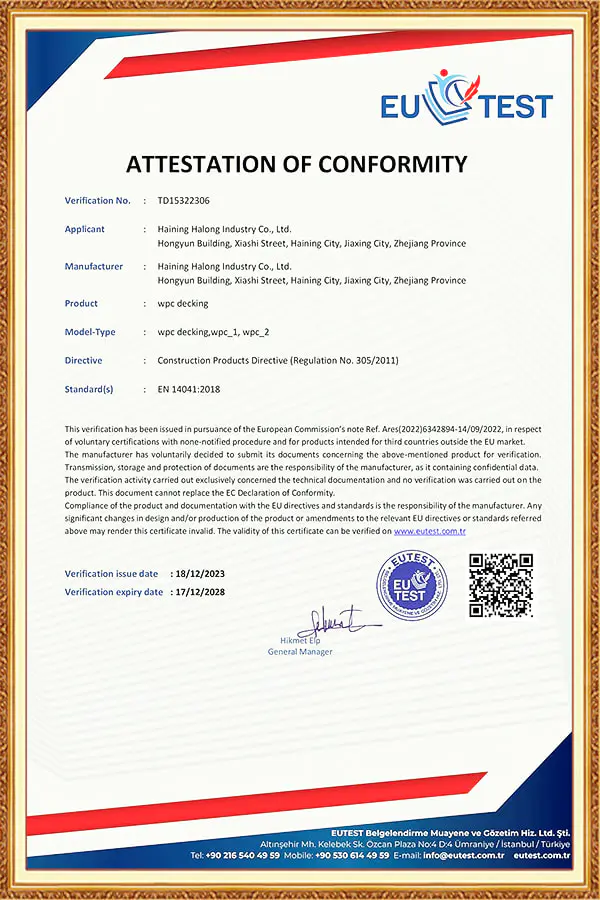

Environmental certification Passed CARB certification, CE certification (EU), China Environmental Labeling (Ten-Ring Certification).

Special ProcessEdge sealing : Ultrasonic welding technology prevents the sound bridge effect and improves the overall sound insulation performance.

Anti-mildew treatment : Nano silver ion coating, antibacterial rate ≥ 99%, suitable for humid environment.

Established in 2005, our factory started with producing PVC Ceiling and Wall Panels, and has grown to be a professional China PVC ceiling panels manufacturer and a wholesale PVC panels factory, committed to providing our customers with high-quality products and services. After 20 years of development, we now own 5 large factories: Haining Halong PVC Ceiling Factory, Haining Longtime Film Factory, Guangxi PVC Wall Panel Factory, Indonesia PVC Wall Panel Factory, and Vietnam PVC Wall Panel Factory.

Our main products include: PVC Ceiling Panels, PVC Wall Panels, WPC Wall Panels, Hot Stamping Foil, PVC Lamination Film, SPC Flooring, WPC Decking, and other related products. Our annual sales can reach up to 35 million USD.

Industry Background and Application Importance In modern commercial and residential interior construction, wall panel systems are increasingly evaluated not only on aesthetics, but...

View MoreIndustry Background and Application Importance Decorative surface materials play a critical role in modern construction, interior systems, and modular building solutions. Tradition...

View MoreIndustry Background and Application Significance In modern construction, the choice of materials significantly impacts the durability, performance, and maintenance costs of a build...

View MoreRemoving PVC Self-Adhesive Wall Sticker from glass surfaces can be a challenging task if not approached correctly. The process requires understanding the adhesive properties, the t...

View More