Material SPC (stone powder + PVC resin + stabilizer) composite board

Size

Standard specifications: 1220mm×2440mm (support customized width ≤1220mm, length ≤3000mm)thickness 6mm-25mm (conventional thickness: 8mm, 10mm, 12mm)

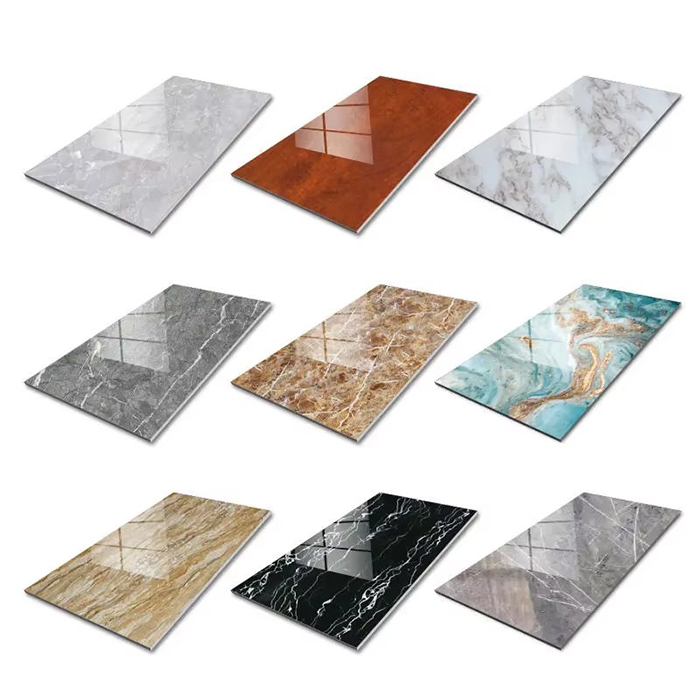

Surface treatment UV paint, wood grain transfer, stone grain imitation, solid color (matte/gloss)

Color

Natural wood color, stone color, solid color (support Pantone color customization)

Impact resistance No cracks after dropping the ball at a height of 50cm (ASTM D2794 standard)

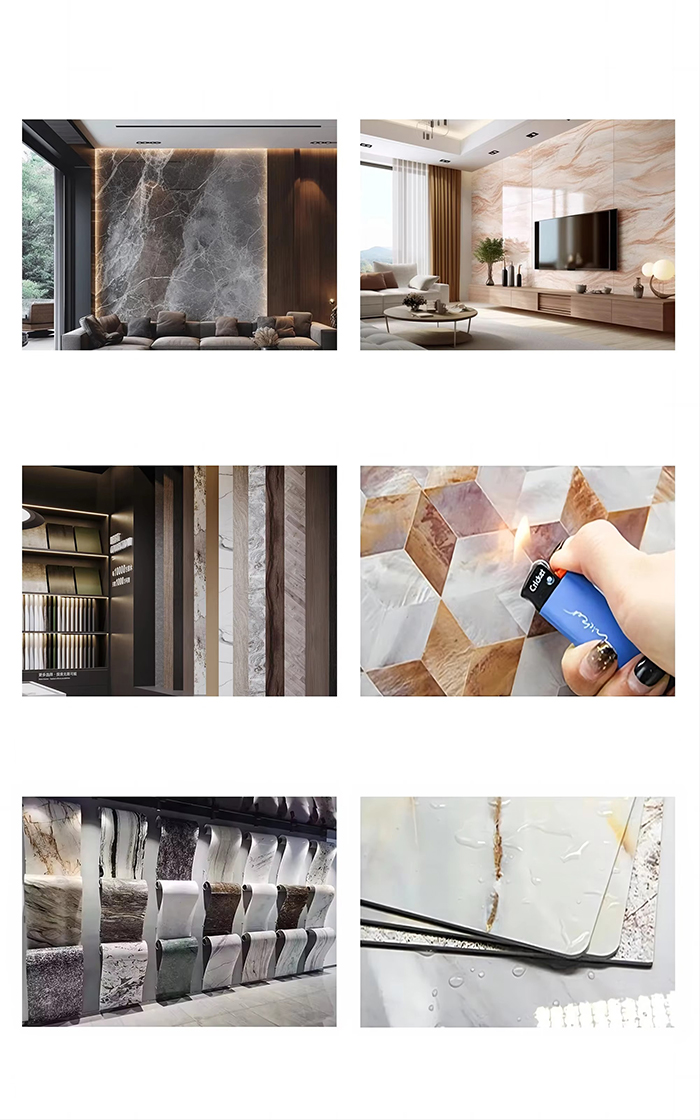

Moisture resistance Water absorption expansion rate ≤ 0.2% (GB/T 17657 standard, 24-hour water immersion test)

Fire rating B1 flame retardant (GB 8624 standard)

Formaldehyde emission≤0.05mg/m³ (EN 717-1 standard, E0 environmental protection level)

Density 1.2-1.5g/cm³ (SPC substrate + UV coating)

Weight About 3.0kg/m² (taking 12mm thickness as an example, which is 1/3 of solid wood board)

Temperature resistance -40℃ to 60℃ (no deformation during long-term use)

Service life ≥20 years (indoor environment)

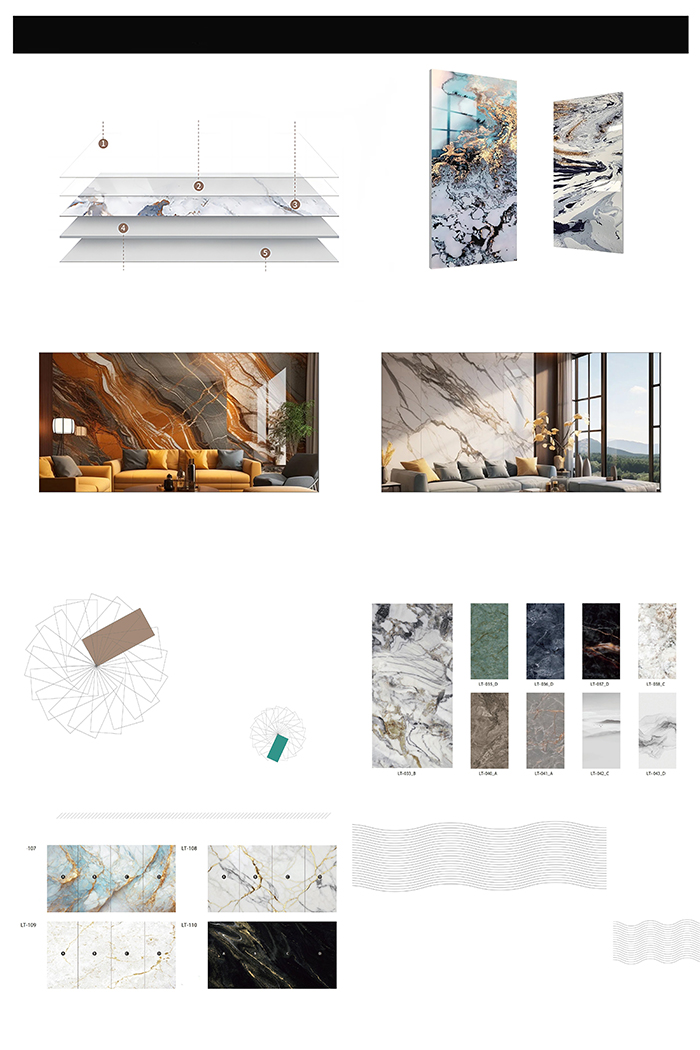

SPC wallboard, or Stone Plastic Composite wallboard, is a new type of building decoration material. It is mainly composed of raw materials such as stone powder (calcium carbonate) and polymer resin (PVC), and has a multi-layer structure, including UV coating, PVC film and PVC stone plastic composite material layer. This wallboard combines the durability of stone and the flexibility of plastic, and is designed for fast installation. It is usually installed with a snap-on system and steel clips, which is faster and more economical than the installation of traditional materials such as tiles or marble.

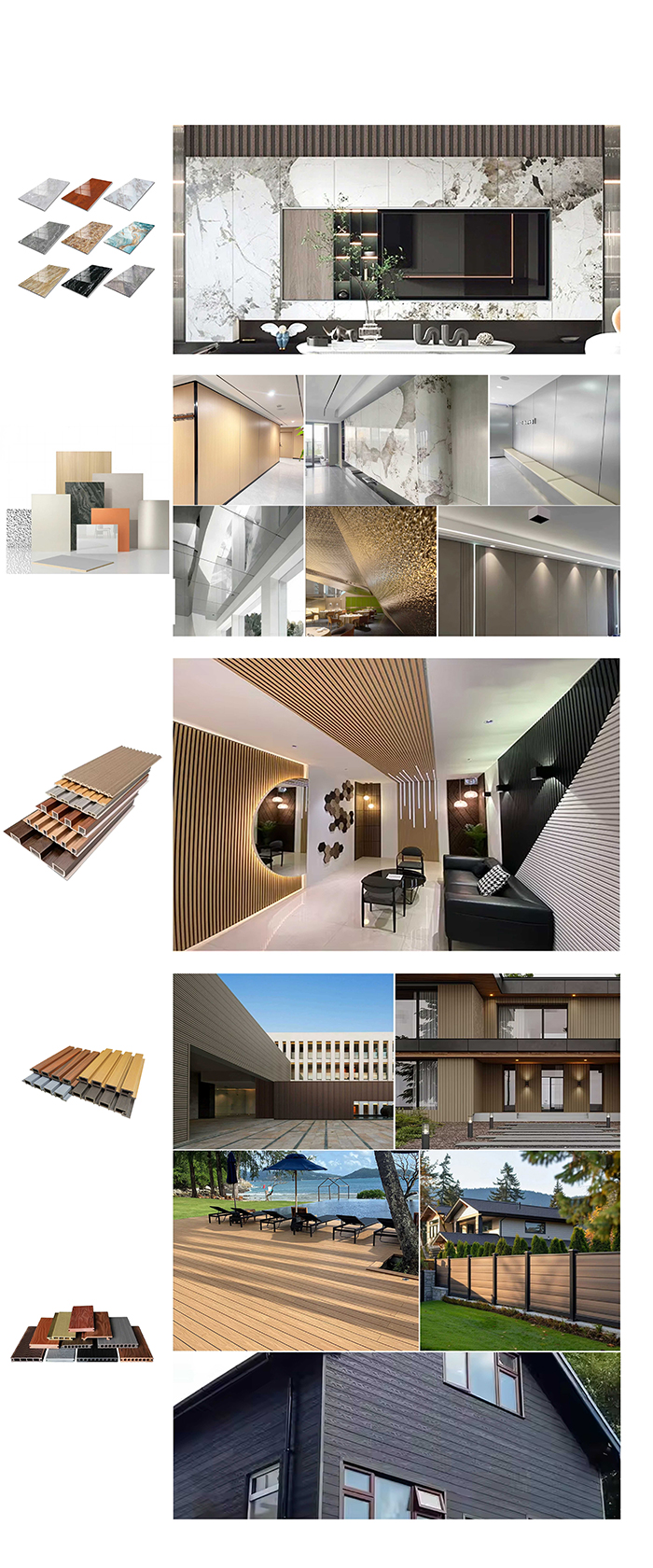

Application scenarios and scope of application

Residential decoration: It can be used for wall decoration in living rooms, bedrooms, kitchens, bathrooms, balconies, etc. It can imitate the texture of natural materials such as wood grain and stone grain, add natural beauty, and provide sound insulation.

Commercial space: It is suitable for wall and floor decoration in shopping malls, hotels, restaurants, offices, retail stores and other places to enhance the grade and image of the space and meet the use needs of high-traffic areas.

Public buildings: SPC wall panels are also commonly used in public buildings such as schools, hospitals, and libraries. Its environmental protection, fire resistance, wear resistance, and waterproof performance meet the safety and use requirements of public buildings.

Special areas: such as areas that need to be quickly renovated or renovated, and places with special requirements for fire resistance, waterproofness, moisture resistance, etc., such as basements.

Product Features/Advantages

Waterproof and moisture-proof: The main ingredients make it waterproof and moisture-proof, suitable for humid environments, and not easy to mold and deform.

Fireproof and flame retardant: The fireproof performance reaches B1 level, which is a flame-retardant material and can effectively prevent the spread of fire.

Wear-resistant and scratch-resistant: The wear-resistant layer on the surface makes it highly wear-resistant, can withstand daily friction and wear, and remain beautiful and durable.

Sound insulation and heat insulation: It has good sound insulation and heat insulation performance, can reduce external noise and reduce indoor heat loss.

Environmentally friendly and healthy: It uses environmentally friendly raw materials, does not contain harmful substances, meets national environmental protection standards, and can be recycled and reused.

Easy to install: There are various installation methods, such as snap-on, pasting, steel clips, etc., which are fast to install and save time and cost.

Easy to clean and maintain: The surface is smooth, not easy to be stained with dirt, and it is easy to clean. Just wipe it with a damp cloth.

Beautiful and diverse: The surface texture and color are rich, and it can present the appearance of a variety of natural materials to meet different decoration needs.

Technology and process

Raw material ratio and mixing: accurately ratio stone powder, PVC resin, stabilizer and other raw materials, fully mix them through a high-speed mixer to ensure uniform distribution of raw materials, and provide a basis for subsequent molding.

Extrusion molding: after the mixed raw materials are heated and melted by an extruder, they are extruded and molded through a mold to form an SPC substrate with a certain thickness and width.

During the extrusion process, parameters such as temperature, pressure and speed are strictly controlled to ensure the quality and performance of the substrate.

Cooling and shaping: the extruded substrate needs to be cooled by a cooling and shaping device to make it solidify quickly and maintain a stable shape and size.

The cooling method usually adopts air cooling or water cooling, and the appropriate cooling method is selected according to the thickness and material of the substrate.

Surface treatment: the surface treatment of the substrate after cooling and shaping is carried out. Common treatment methods include lamination, printing, etc.

Lamination can enhance the wear resistance and waterproofness of the wallboard, and printing can give the wallboard a variety of different patterns and textures to meet different decoration needs.

Quality inspection: during the production process, the SPC wallboard is strictly inspected for quality, including dimensional accuracy, flatness, density, fire resistance, environmental protection performance and other aspects to ensure that the product meets relevant standards and quality requirements.

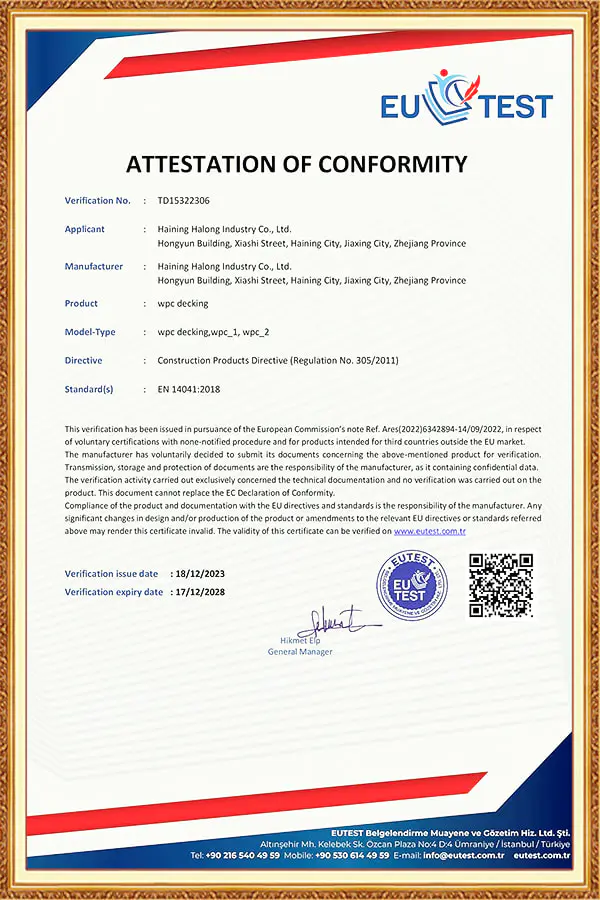

Established in 2005, our factory started with producing PVC Ceiling and Wall Panels, and has grown to be a professional China PVC ceiling panels manufacturer and a wholesale PVC panels factory, committed to providing our customers with high-quality products and services. After 20 years of development, we now own 5 large factories: Haining Halong PVC Ceiling Factory, Haining Longtime Film Factory, Guangxi PVC Wall Panel Factory, Indonesia PVC Wall Panel Factory, and Vietnam PVC Wall Panel Factory.

Our main products include: PVC Ceiling Panels, PVC Wall Panels, WPC Wall Panels, Hot Stamping Foil, PVC Lamination Film, SPC Flooring, WPC Decking, and other related products. Our annual sales can reach up to 35 million USD.

Industry Background and Application Importance In modern commercial and residential interior construction, wall panel systems are increasingly evaluated not only on aesthetics, but...

View MoreIndustry Background and Application Importance Decorative surface materials play a critical role in modern construction, interior systems, and modular building solutions. Tradition...

View MoreIndustry Background and Application Significance In modern construction, the choice of materials significantly impacts the durability, performance, and maintenance costs of a build...

View MoreRemoving PVC Self-Adhesive Wall Sticker from glass surfaces can be a challenging task if not approached correctly. The process requires understanding the adhesive properties, the t...

View More