Material Polyvinyl chloride (PVC) substrate + acrylic adhesive layer + protective film (release paper/silicone oil paper)size

Standard specifications: 1220mm×2440mm (support customized width ≤1220mm, length ≤3000mm)

Thickness 0.1mm-0.5mm (conventional thickness: 0.2mm, 0.3mm, 0.4mm)

Viscosity Initial adhesion ≥1.5N/25mm (rolling ball test), peel strength ≥15N/cm (ASTM D3359 standard)

Temperature resistance -20℃ to 60℃ (no debonding or warping during long-term use)

Waterproof Water absorption ≤0.2% (GB/T 17657 standard, 24-hour water immersion test)

Tensile strength ≥18MPa (longitudinal) / ≥12MPa (transverse) (GB/T 1040 standard)

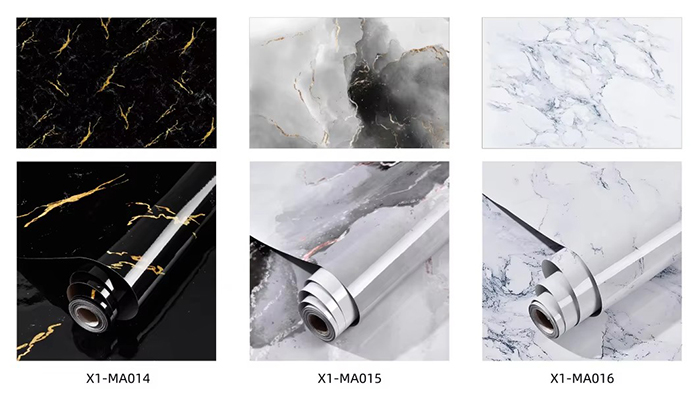

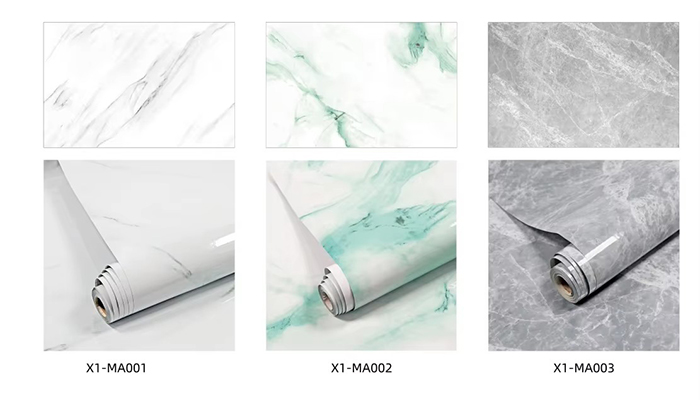

Environmental standards Compliant with RoHS, REACH, EN71-3 (heavy metal ≤ 0.01mg/kg)color Transparent, porcelain white, wood grain, stone grain, metallic color, gradient effect (support Pantone color customization)

Surface treatment UV coating (matte/glossy), scratch-resistant (pencil hardness ≥ 2H)

PVC adhesive wall stickers are self-adhesive decorative materials with polyvinyl chloride (PVC) film as the base material, a printed layer on the surface, and acrylic pressure-sensitive adhesive on the back. Its core features include high viscosity, zero formaldehyde, and removable and reusable. They are suitable for indoor and outdoor walls, furniture, glass and other scenes, replacing traditional wallpaper, paint and spray-painted advertisements.

Home Improvement

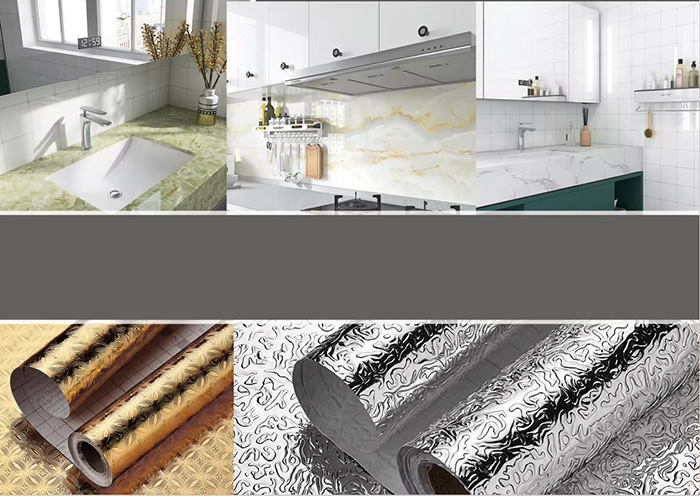

Wall decoration Imitation wood grain, stone grain, and metal brushed effects, suitable for living rooms, bedrooms, children's rooms, etc.

Furniture Refurbishment : Directly stick to the surface of cabinets, door panels, tables and chairs without sanding primer.

Commercial Space

Advertising display : Light transmittance ≥85% (transparent substrate), built-in LED light source to achieve three-dimensional luminous effect.

Shop Sign : Waterproof and UV-resistant (UPF 50+), suitable for outdoor windows and glass curtain walls.

Public Facilities

Hospital/School : Antibacterial rate ≥95% (nano silver ion coating), chemical corrosion resistance (pH 1-14).

Subway station/Airport : Fireproof grade B1 (UL94 V-0), anti-scratch (Taber 5000 turns without bottom exposure).

Special scenarios

Glass partition Strong adhesion (peel strength ≥ 15N/cm), suitable for smooth glass and acrylic surfaces.

Car interior: High temperature resistance of 80℃, anti-aging (QUV test for 500 hours without yellowing).

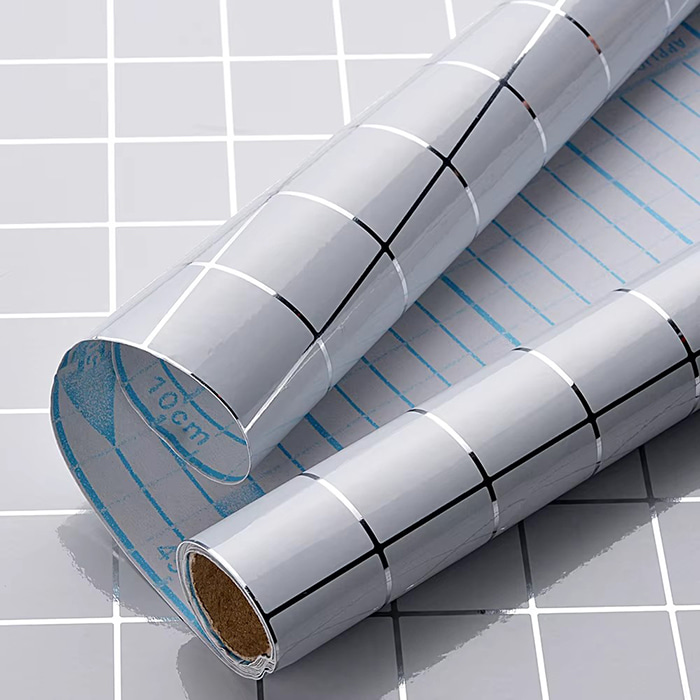

Stick and use

Comes with self-adhesive backing, no glue or keel required, can be directly pasted on a flat surface (ceramic tiles, glass, wood boards, etc.).

Environmental safety

No formaldehyde, no VOC emissions, meets ENF grade standards, and can be removed and reused (repeated pasting ≥5 times).

Diversified Design

Supports full-color printing (1200dpi resolution), gradient effect, and three-dimensional relief (electric engraving mold pressing).

Strong adhesion and durability

Adhesive peel strength ≥15N/cm, anti-aging (weather resistance up to level 5, QUV test 500 hours).

Waterproof and stain-resistant The surface UV coating is anti-penetration (water absorption rate ≤ 0.2%) and can be cleaned by wiping with alcohol or soapy water.

Cost-effective

The cost is only 1/3 of wallpaper, and the construction efficiency is increased by 70% (single person per day paving area ≥50㎡ ).

Flexible cutting

It can be cut directly with a utility knife, with a minimum size of 5cm×5cm, suitable for special-shaped spaces (such as curved walls).

Substrate preparation

PVC film forming : Polyvinyl chloride resin (S-70) + plasticizer (DOTP) + stabilizer (Ca-Zn), calendering process thickness error ≤±0.02mm.

Printing TechnologyGravure printing :Ink adhesion reaches 4B level (ASTM D3359), color difference ΔE≤0.5.

Digital Printing : Inkjet resolution 1200dpi, supports full-color gradient and photo-level patterns.

Adhesive backing

Acrylic pressure sensitive adhesive : Solid content ≥55%, coating thickness 0.05mm-0.1mm, initial adhesion ≥1.5N/25mm.

Release layer:The peeling force of silicone oil paper is ≤0.2N/25mm, anti-adhesion.

Surface treatment

UV Curing Coating :Film thickness ≥10μm, hardness ≥2H (pencil hardness), wear resistance ≥5000 turns.

Anti-scratch treatment : Diamond-like carbon (DLC) coating, pencil hardness ≥ 4H.

Quality Inspection

Adhesion test :Initial adhesion by rolling ball method ≥1.5N/25mm, peel strength ≥15N/cm (ASTM D3359).

Weather resistance : QUV aging test for 500 hours without chalking or fading (ΔE≤1.5).

Environmental testing : RoHS heavy metal detection (lead, cadmium, mercury, etc. ≤100ppm).

Special Process

3D relief : Electric carving mold pressing (depth 0.1-0.3mm), real touch.

Metal Texture Vacuum electroplated aluminum layer (thickness ≥ 2μm), reflectivity ≥ 85%.

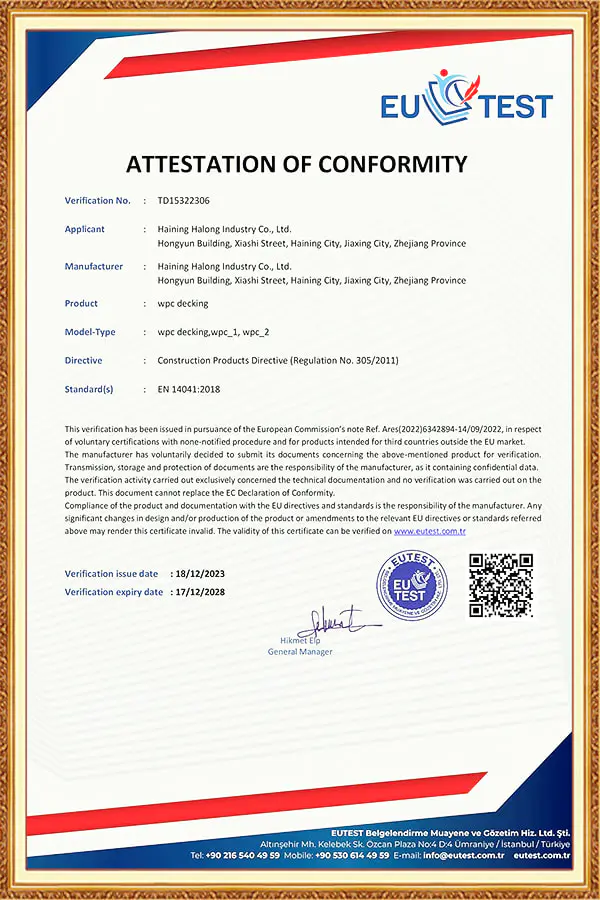

Established in 2005, our factory started with producing PVC Ceiling and Wall Panels, and has grown to be a professional China PVC ceiling panels manufacturer and a wholesale PVC panels factory, committed to providing our customers with high-quality products and services. After 20 years of development, we now own 5 large factories: Haining Halong PVC Ceiling Factory, Haining Longtime Film Factory, Guangxi PVC Wall Panel Factory, Indonesia PVC Wall Panel Factory, and Vietnam PVC Wall Panel Factory.

Our main products include: PVC Ceiling Panels, PVC Wall Panels, WPC Wall Panels, Hot Stamping Foil, PVC Lamination Film, SPC Flooring, WPC Decking, and other related products. Our annual sales can reach up to 35 million USD.

Industry Background and Application Importance Decorative surface materials play a critical role in modern construction, interior systems, and modular building solutions. Tradition...

View MoreIndustry Background and Application Significance In modern construction, the choice of materials significantly impacts the durability, performance, and maintenance costs of a build...

View MoreRemoving PVC Self-Adhesive Wall Sticker from glass surfaces can be a challenging task if not approached correctly. The process requires understanding the adhesive properties, the t...

View MoreThe flooring industry has witnessed significant advancements in recent years, with new materials offering improved durability, aesthetics, and ease of installation. Among these inn...

View More