Material Polyvinyl chloride (PVC resin) + wood fiber/bamboo fiber + calcium carbonate powder + stabilizer

Size

Standard specifications: 1220mm×2440mm (support customized width ≤1220mm, length ≤3000mm)thickness 6mm-25mm (conventional thickness: 8mm, 12mm, 15mm)

Surface treatment UV paint, wood grain transfer, stone grain imitation, solid color (matte/gloss)color Natural wood color, stone color, solid color (support Pantone color customization)

Bending strength ≥120MPa (GB/T 6892 standard)

Moisture resistance Water absorption expansion rate ≤ 0.3% (GB/T 17657 standard, 24-hour water immersion test)

Fire rating B1 flame retardant (GB 8624 standard)

Formaldehyde emission ≤0.05mg/m³ (EN 717-1 standard, E0 environmental protection level)

Density 1.2-1.8g/cm³ (composite structure of wood powder and PVC)

Weight About 2.5kg/m² (taking 12mm thickness as an example, which is 1/4 of the solid wood board)

Temperature resistance -20℃ to 60℃ (no deformation during long-term use)

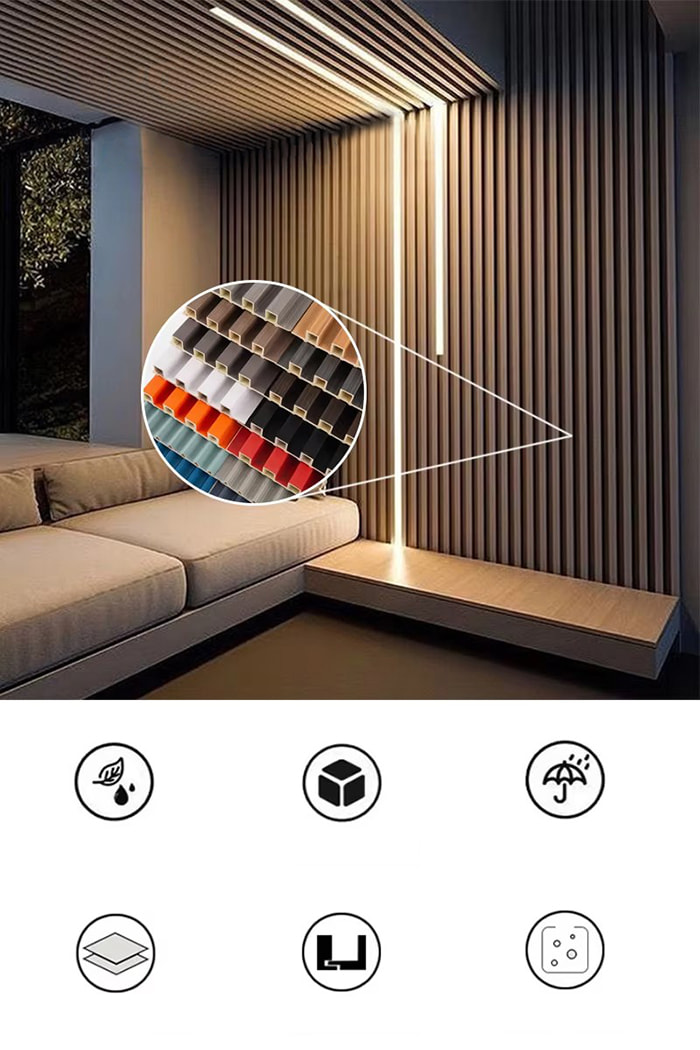

WPC indoor panels are new environmentally friendly decorative panels made of wood fiber or bamboo fiber as the core raw material, compounded with PVC resin, calcium carbonate powder and stabilizer through high temperature and high pressure process. The surface adopts UV coating or high-precision transfer technology to simulate the texture of natural wood and stone, and has the characteristics of waterproof and moisture-proof, mildew-proof and antibacterial, light weight and high strength. It is suitable for indoor walls, ceilings, background walls and other scenes, and is an ideal choice to replace traditional wood veneers and plastic gussets.

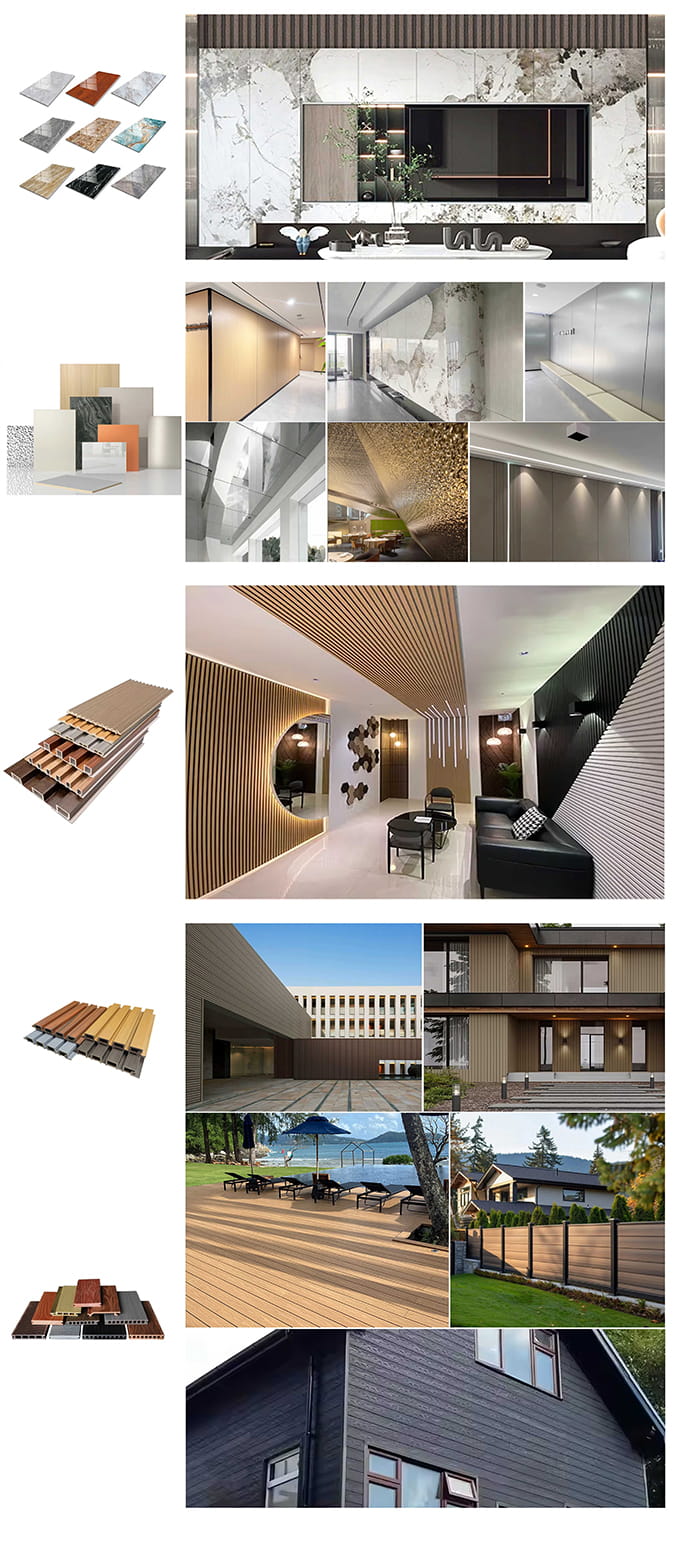

Residential Renovation

Living room/bedroom : Imitation wood grain and stone grain walls, natural, beautiful and easy to clean.Kitchen/Bathroom Excellent moisture-proof performance (water absorption ≤ 0.3%), can directly contact humid environment.

Commercial SpaceHotel/Shopping Mall :The wood grain/stone grain design enhances the texture of the space and supports quick disassembly and renovation (reuse rate ≥ 90%).

Showroom/Office : Sound absorption and noise reduction (noise reduction coefficient NRC ≥ 0.6), improving the acoustic environment.

Public FacilitiesHospital/School : Antibacterial and mildew-proof (antibacterial rate ≥ 99%), strong stain resistance (chemical resistance pH value 3-11).

Nursing home/kindergarten : Rounded corner anti-collision design + antibacterial surface (antibacterial rate ≥ 99%).

Special scenariosComputer room/laboratory:Antistatic treatment (surface resistance ≤1×10⁶Ω), adapted to the environment of precision equipment.

Environmental safety

The raw materials are formaldehyde-free, heavy metal-free, CARB/FSC-certified, and 100% recyclable.

Excellent performance The moisture resistance is better than that of ordinary wood veneer (water absorption expansion rate ≤ 0.3%), and the deformation resistance is outstanding.

It is scratch-resistant (pencil hardness 3H), and the service life is twice that of PVC gusset plate.

Diversified Design Supports more than 100 patterns including wood grain, stone grain, solid color, etc., and can customize gradient and artistic patterns.

Efficient installation Snap-on installation (no glue required), disassembly reuse rate ≥ 90%, construction period shortened by 60%.

Economical The overall cost is lower than that of solid wood panels (the price is about 1/4 of solid wood), and the maintenance cost is low (no need to paint or refresh).

Fire safety B1 grade flame retardant (flame spread time ≥ 30 minutes), in line with fire protection requirements for public places.

Raw material handling

Wood fiber extraction : The wood is carbonized and crushed into 40-60 mesh fibers, retaining the toughness of natural wood fibers.

PVC mixed with filler : PVC resin and calcium carbonate powder are mixed in proportion to enhance the rigidity of the board.

Composite process

Extrusion :High temperature (180℃-220℃) and high pressure (15kg/cm²) compounding, thickness error ≤±0.2mm.

Surface treatment

UV paint : Three-coat-one-bake process, film thickness ≥30μm, wear resistance up to 4000 revolutions (Taber test).

Wood grain transfer : Vacuum thermal transfer technology, texture clarity up to 1200dpi, adhesion ≥ level 1 (ASTM D3359).

Quality Inspection

Fire test : GB 8624 standard, B1 flame retardant.

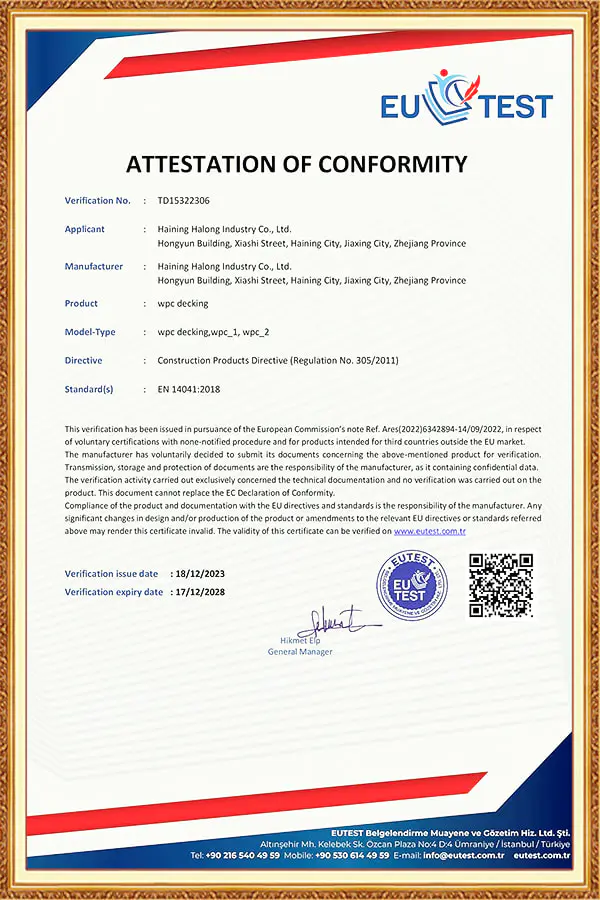

Environmental certification : Passed CARB certification, Ten-Ring certification, CE certification (EU).

Special Process

Anti-corrosion structure:Some products use carbon fiber anti-corrosion layer + hydrophobic hole design to improve corrosion resistance and elasticity.

Established in 2005, our factory started with producing PVC Ceiling and Wall Panels, and has grown to be a professional China PVC ceiling panels manufacturer and a wholesale PVC panels factory, committed to providing our customers with high-quality products and services. After 20 years of development, we now own 5 large factories: Haining Halong PVC Ceiling Factory, Haining Longtime Film Factory, Guangxi PVC Wall Panel Factory, Indonesia PVC Wall Panel Factory, and Vietnam PVC Wall Panel Factory.

Our main products include: PVC Ceiling Panels, PVC Wall Panels, WPC Wall Panels, Hot Stamping Foil, PVC Lamination Film, SPC Flooring, WPC Decking, and other related products. Our annual sales can reach up to 35 million USD.

Industry Background and Application Importance In modern commercial and residential interior construction, wall panel systems are increasingly evaluated not only on aesthetics, but...

View MoreIndustry Background and Application Importance Decorative surface materials play a critical role in modern construction, interior systems, and modular building solutions. Tradition...

View MoreIndustry Background and Application Significance In modern construction, the choice of materials significantly impacts the durability, performance, and maintenance costs of a build...

View MoreRemoving PVC Self-Adhesive Wall Sticker from glass surfaces can be a challenging task if not approached correctly. The process requires understanding the adhesive properties, the t...

View More