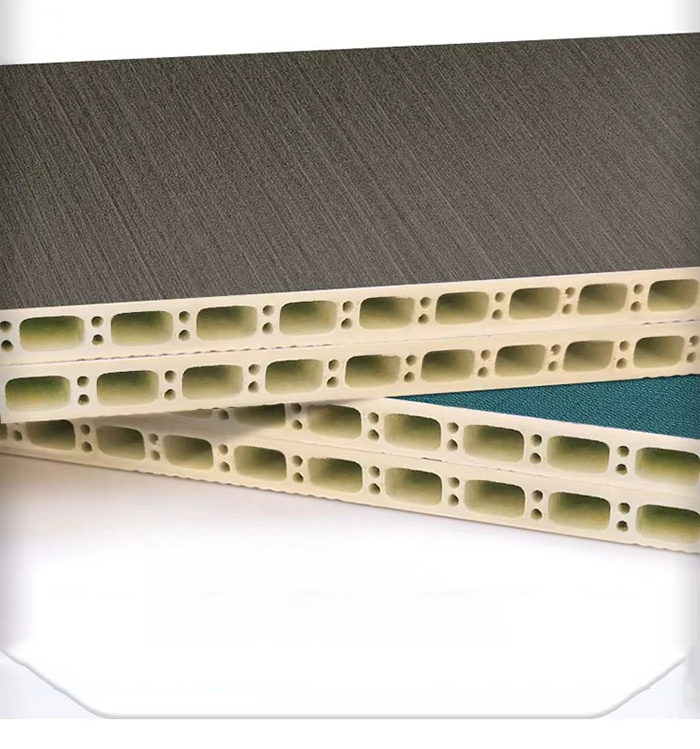

Raw materials: bamboo fiber, PVC resin, calcium powder, etc.

Density Generally, the higher the density, the better the strength and wear resistance.

Strength: good hardness and toughness, not easy to deform.

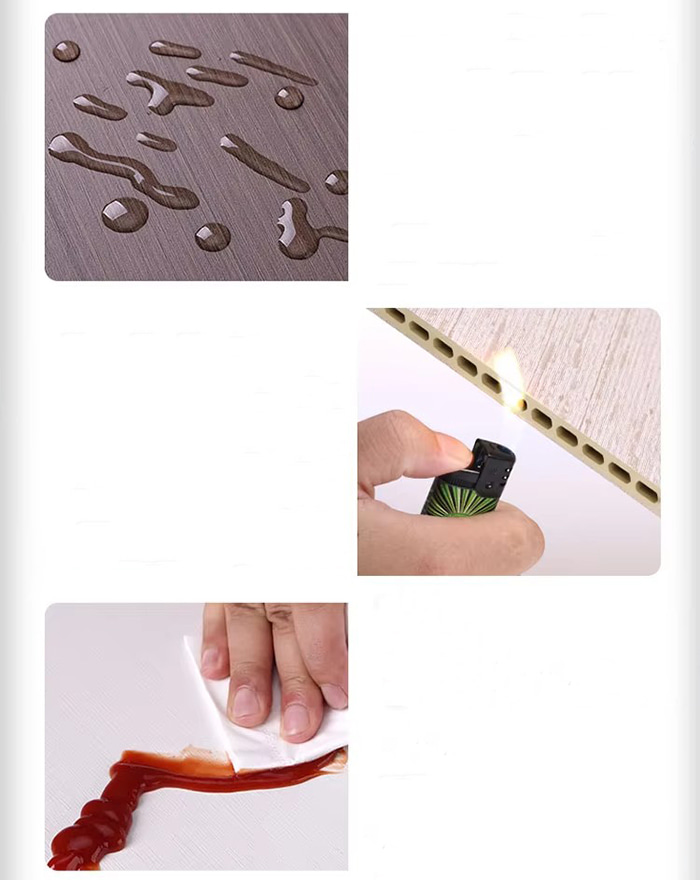

Waterproof: remarkable waterproof performance, suitable for humid environment.

Fireproof: a certain fireproof grade, can slow down the spread of fire.

Wear resistance: the surface has been specially treated, with good wear resistance.

Specifications: Length: generally 2.4-4 meters, width: 0.2-0.6 meters, thickness: 6-12 mm

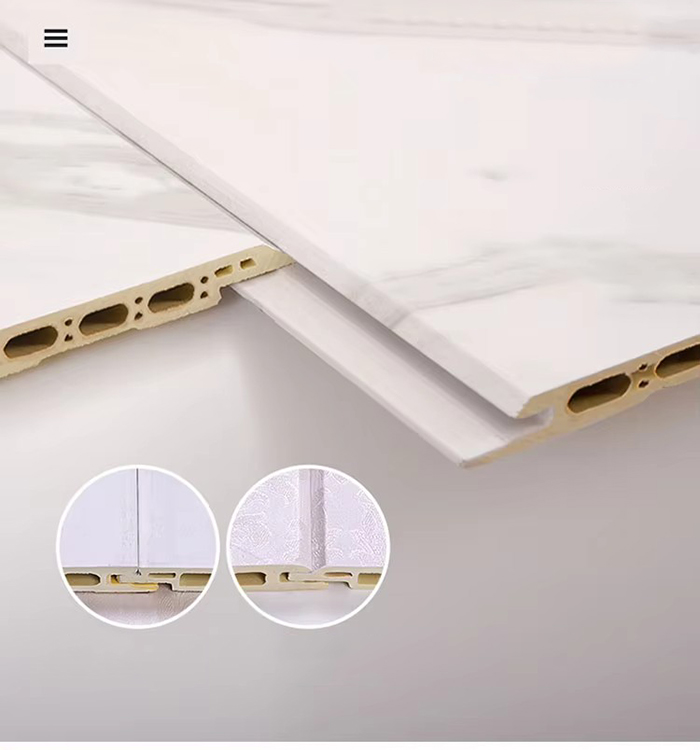

Bamboo fiber wallboard is a new type of environmentally friendly wall decoration material, made of bamboo fiber, PVC resin, calcium powder and other raw materials through high temperature and high pressure extrusion molding process. Its surface is usually covered with decorative film, providing a variety of beautiful textures and colors, such as imitation wood grain, bamboo grain, etc. This kind of wallboard has many advantages such as environmental protection, waterproof, moisture-proof, mildew-proof, fire-proof, sound insulation, heat preservation, etc., and it is easy to install and can be directly installed on the wall of the rough house without complicated pre-processing.

Indoor decoration: Suitable for wall decoration in living rooms, bedrooms, dining rooms and other spaces, which can add a natural and warm atmosphere.

Kitchen and bathroom: Due to its waterproof and moisture-proof properties, it is very suitable for the walls and ceilings of kitchens and bathrooms.

Commercial space: It can be used for the decoration of commercial places such as hotels, restaurants, cafes, offices, etc., showing a unique decorative style.

Public space: It is suitable for the decoration of public spaces such as office buildings, exhibition halls, conference halls, etc., providing a comfortable and natural environment.

Furniture making: It can be used to make furniture such as wardrobes, bookcases, bedside tables, etc.

Exterior wall decoration: It has the characteristics of good weather resistance and UV resistance, and can be used for the decoration of the exterior walls of buildings.

Landscape decoration: It can be used for landscape decoration such as walls and fences in parks, gardens, courtyards and other places.

Product Features/Advantages

Environmental performance: No glue is added during the production process, no harmful substances such as formaldehyde are released, and it meets the E0 environmental protection standard.

Waterproof and moisture-proof: It has good waterproof and moisture-proof performance and is not easily deformed by moisture. Fireproof performance: It reaches a certain fireproof level and can effectively slow down the spread of fire.

Sound insulation and heat preservation: It has certain sound insulation and heat preservation effects, which can improve indoor comfort.

Decorative effect: The surface texture and color are rich and varied, and can be customized according to needs to meet the decoration needs of different styles.

Easy installation: The installation process is simple and quick, which can shorten the decoration period.

Easy maintenance: The surface is easy to clean, just wipe it with a damp cloth.

Technology and process

Raw material mixing: Mix bamboo fiber, PVC resin, calcium powder and other raw materials in a certain proportion to ensure the uniformity and performance of the materials.

High temperature and high pressure extrusion molding: The mixed materials are extruded and molded through high temperature and high pressure process to form a solid board.

Surface decoration treatment: The decorative film high temperature lamination or roller coating process is used to provide the wallboard with beautiful appearance and additional protection.

Micro-foaming process: The micro-foaming process is used in the production process to make the board light and high-strength.

Established in 2005, our factory started with producing PVC Ceiling and Wall Panels, and has grown to be a professional China PVC ceiling panels manufacturer and a wholesale PVC panels factory, committed to providing our customers with high-quality products and services. After 20 years of development, we now own 5 large factories: Haining Halong PVC Ceiling Factory, Haining Longtime Film Factory, Guangxi PVC Wall Panel Factory, Indonesia PVC Wall Panel Factory, and Vietnam PVC Wall Panel Factory.

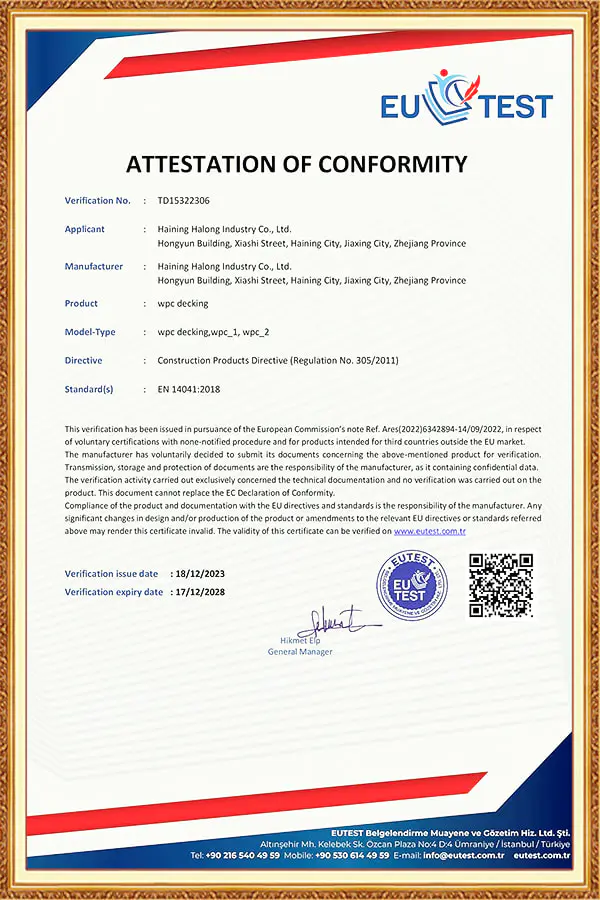

Our main products include: PVC Ceiling Panels, PVC Wall Panels, WPC Wall Panels, Hot Stamping Foil, PVC Lamination Film, SPC Flooring, WPC Decking, and other related products. Our annual sales can reach up to 35 million USD.

Industry Background and Application Importance In modern commercial and residential interior construction, wall panel systems are increasingly evaluated not only on aesthetics, but...

View MoreIndustry Background and Application Importance Decorative surface materials play a critical role in modern construction, interior systems, and modular building solutions. Tradition...

View MoreIndustry Background and Application Significance In modern construction, the choice of materials significantly impacts the durability, performance, and maintenance costs of a build...

View MoreRemoving PVC Self-Adhesive Wall Sticker from glass surfaces can be a challenging task if not approached correctly. The process requires understanding the adhesive properties, the t...

View More