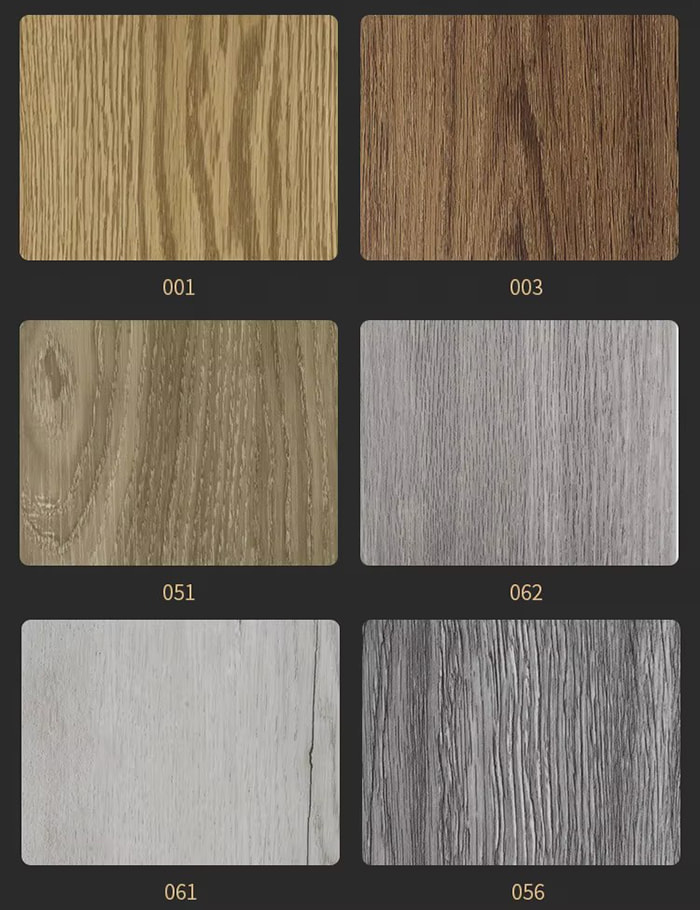

Material Polyvinyl chloride (PVC) resin powder + calcium carbonate powder (CaCO₃ ) + Wear-resistant layer (UV/color film)

Specification Standard size: 1220×180×7.0mm (thickness optional 3.2mm-20mm)

Density 1.9-2.1g/cm³ (substrate layer)

Fire rating B1 flame retardant (GB 8624 standard), some models reach A2 level (EN 13501-1)

Formaldehyde emission≤0.02mg/m³ (EN 717-1 standard, ENF environmental protection level)

Anti-slip level R9-R10 (friction coefficient of wet surface ≥ 0.5)

Abrasion resistance T grade (≥8000 rpm, GB/T 18102 standard)

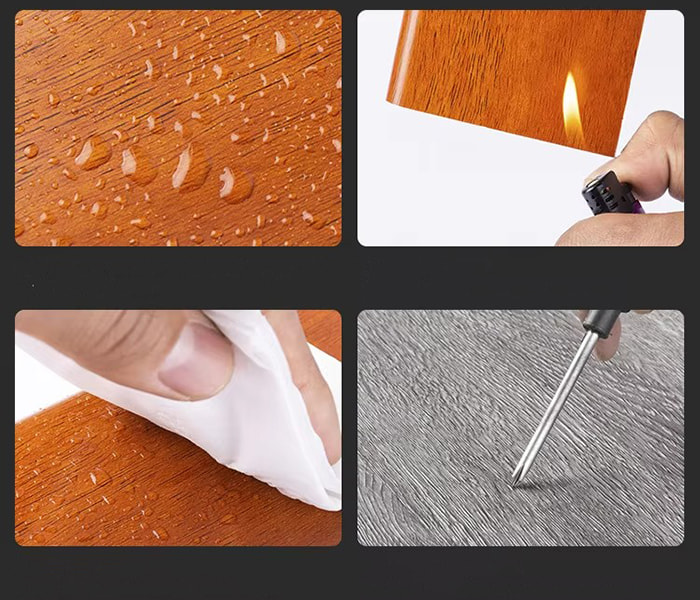

Water absorption ≤0.5% (GB/T 17657 standard, 24-hour water immersion test)

Quiet performance Noise reduction 32dB (EN 14041 standard)

Shrinkage ≤0.01% (80℃/6h test)

Temperature resistance -40℃ to 60℃ (no deformation during long-term use)

Weight About 2.5kg/m² (taking 7mm thickness as an example, which is 1/3 of solid wood flooring)

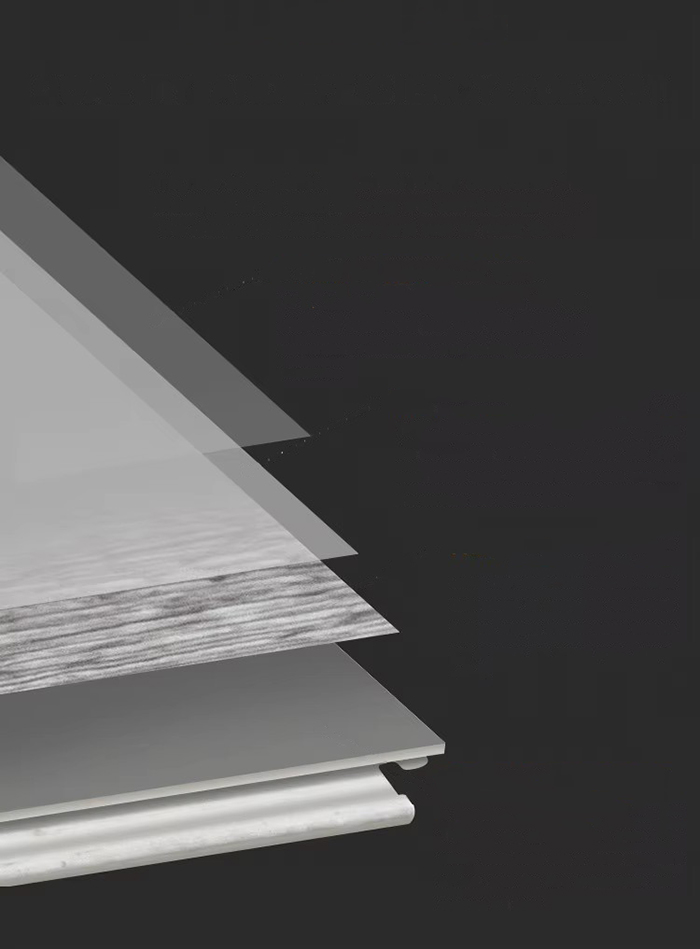

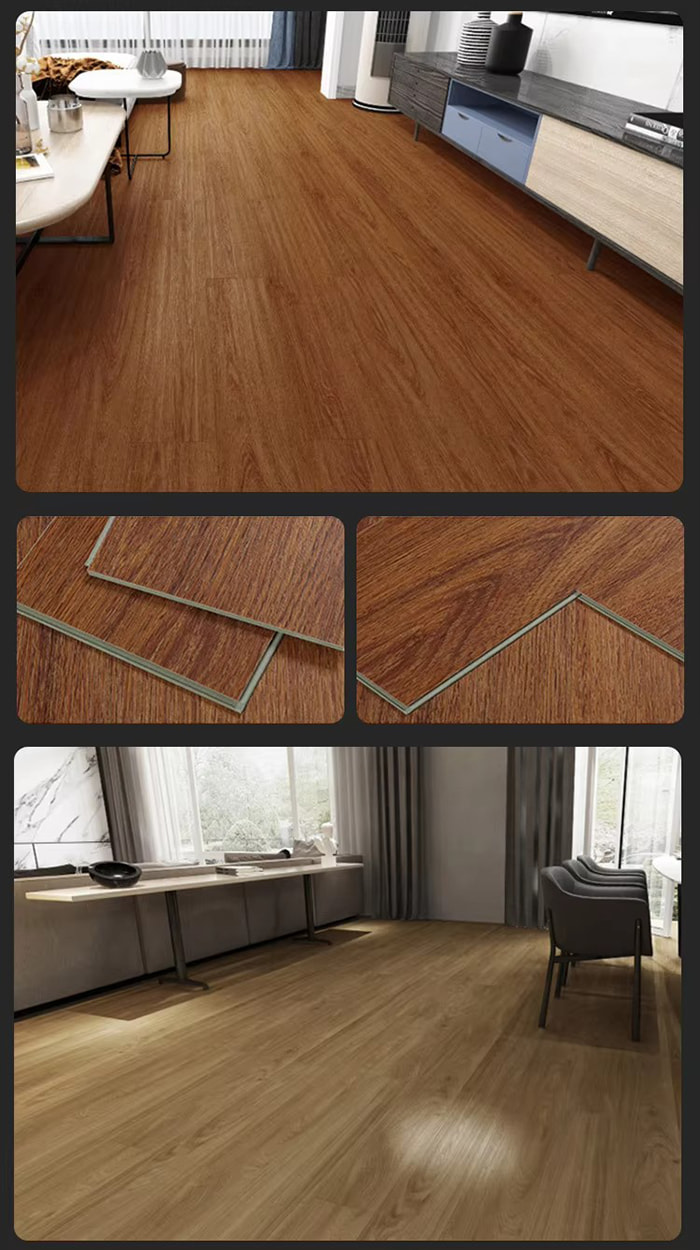

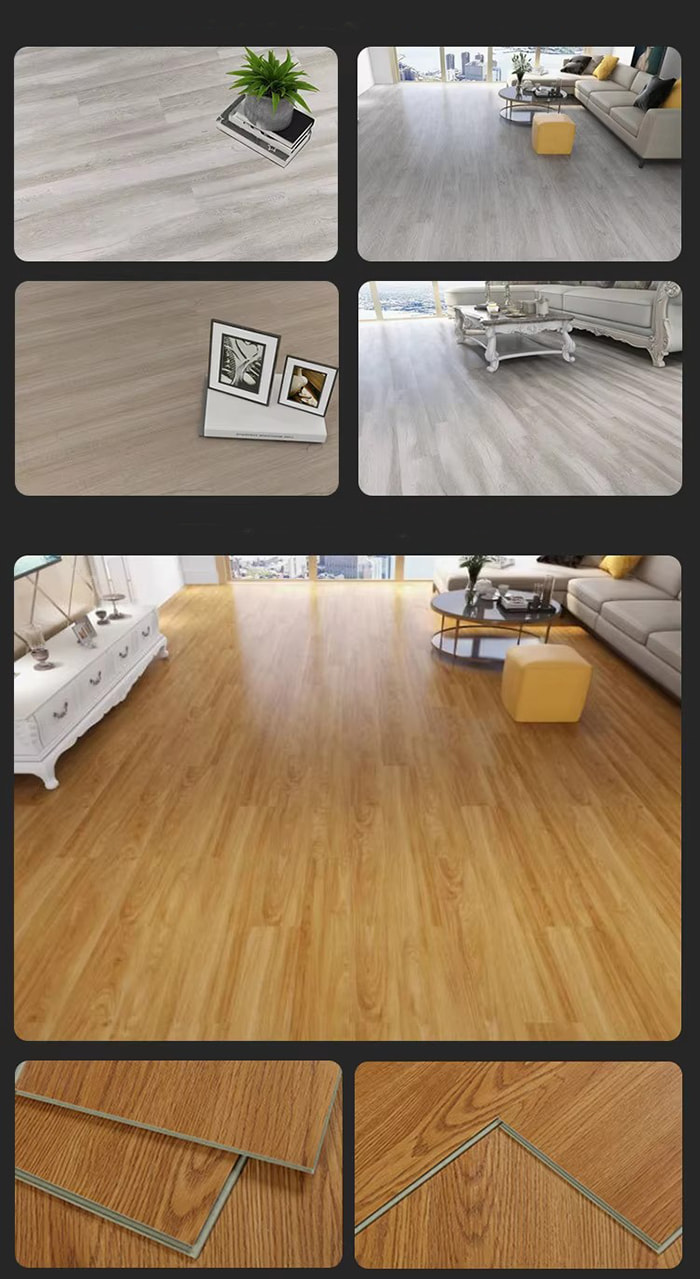

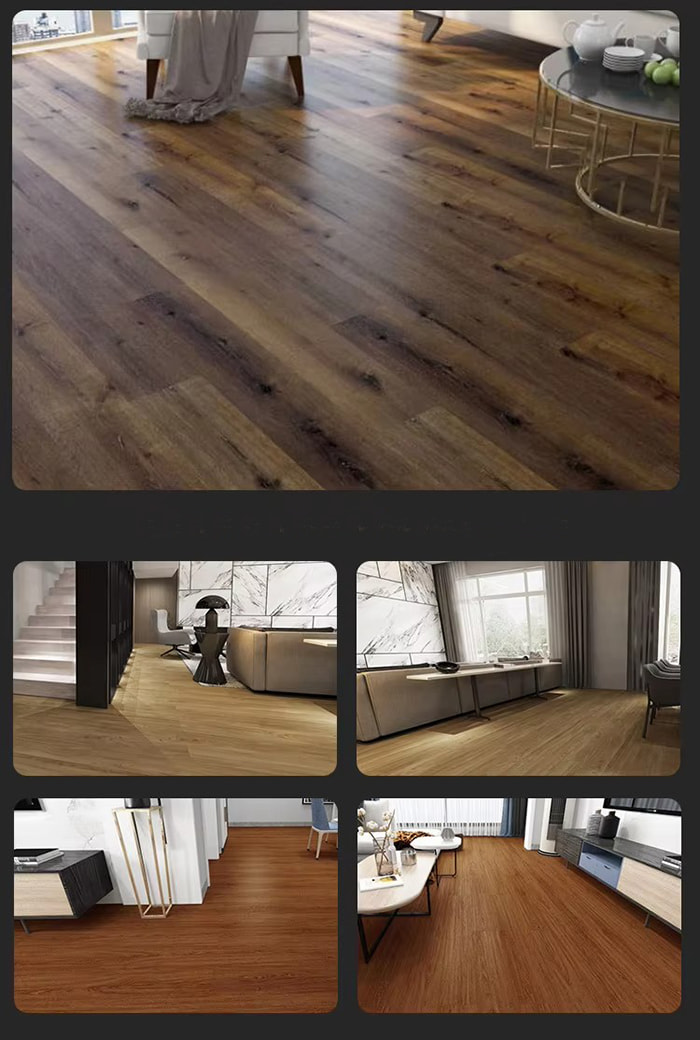

SPC floor (Stone Plastic Composite) is a composite floor made of polyvinyl chloride (PVC) resin powder and calcium carbonate powder as the core raw materials, formed by high temperature and high pressure process. Its structure is divided into four layers: wear-resistant layer (UV coating), color film decorative layer, stone powder base material layer and silent layer, with a variety of surface effects such as wood grain and stone grain. It has the characteristics of zero formaldehyde, waterproof and moisture-proof, and smoke-scald resistance, and is suitable for indoor and outdoor floor decoration, especially for floor heating systems.

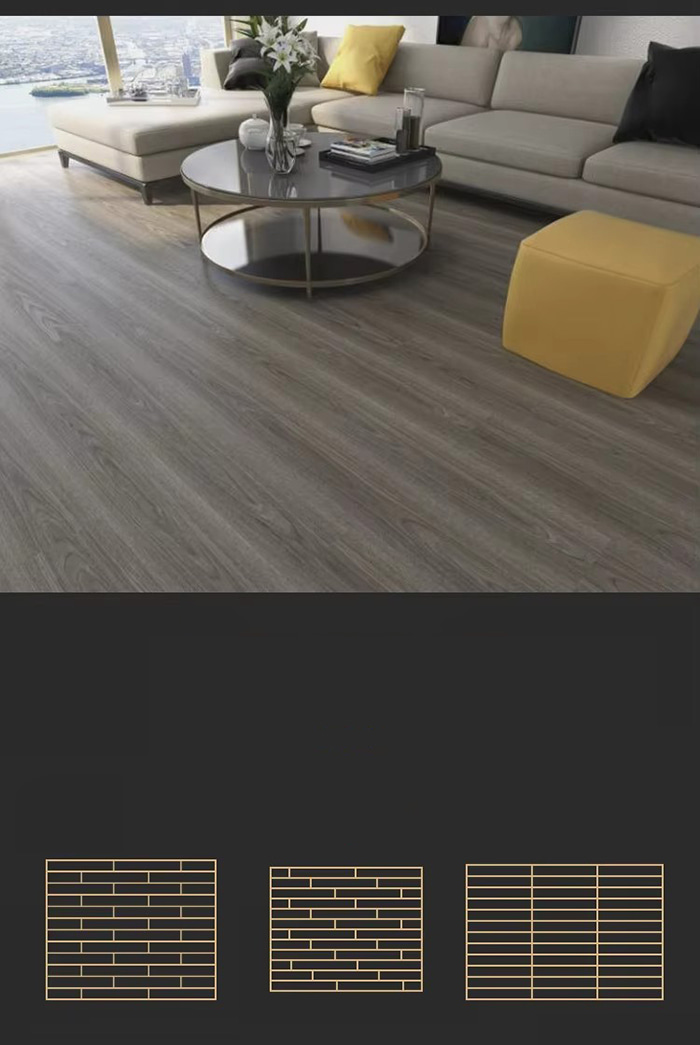

Family Space

Kitchen/Bathroom : Waterproof and moisture-proof (water absorption rate ≤ 0.5%), can resist oil and water penetration.

Floor heating environment : Strong thermal stability (thermal conductivity 0.045W/m·K), no formaldehyde release, suitable for scenarios where solid wood composite flooring cannot be used.

Commercial Places

Shopping mall/hospital : Anti-slip grade R10 (friction coefficient of slippery surface ≥0.6), antibacterial and mildew-proof (antibacterial rate ≥95%), in line with the hygiene standards of public places.

Hotel/Showroom : The lock installation does not require glue, it is ready to use after installation, and supports quick renovation.

Public FacilitiesSchool/subway station : Fireproof grade B1 (flame spread time ≥ 30 minutes), strong impact resistance (load ≥ 1000kg/m²).

Gym/Dance

Studio : Elastic base relieves sports impact, non-slip surface ensures safety.

Special scenarios

Outdoor terrace/poolside : Acid and alkali corrosion resistance (Class 0), adaptable to extreme climates.

Renovation of old houses : Ultra-thin design (3.2mm) saves layer height and directly covers the old floor.

Environmental safety

Zero formaldehyde, no heavy metals (soluble heavy metals ≤ 0.01mg/kg), in line with ENF grade standards.

Recyclability ≥ 90%, no glue in the production process, no VOC emissions.

Excellent performance

Waterproof No expansion after immersion for 72 hours, can be used in underwater environment (such as swimming pool) for a long time.

Wear resistance : The surface wear-resistant layer reaches T level and the service life exceeds 10 years (traffic flow ≥ 5000 times/day).

Fire resistance : B1 grade flame retardant, self-extinguishing when encountering fire, no smoke or toxic gas release.

Easy installation

Lock-on installation (tolerance ≤ 0.1mm), no keel required, shortening construction period by 60%. Supports cutting and splicing, adapting to special-shaped spaces (such as curved walls and stair treads).

Economical and practical

The cost is only 1/3 of that of solid wood flooring, and the maintenance cost is low (no waxing, pollution-resistant).

It can be disassembled and reassembled twice, and the old floor does not need to replace the base material.

Comfort

The silent layer reduces noise by 32dB, feels close to solid wood, and has an elastic modulus of ≥2000MPa.

The thermal conductivity is 0.045W/m·K, which is suitable for floor heating systems and increases energy efficiency by 20%.

Raw material handling

Substrate preparation PVC resin powder (50%) + calcium carbonate powder (45%) + stabilizer (5%), hot mixed (125℃) in a high-speed mixer and then cold mixed (55℃).

Surface coating : UV curing coating (film thickness ≥ 20μm), wear resistance increased by 30%.

Molding process

Extrusion : Twin-screw extruder (temperature 170-195℃) continuously extrudes the base material, and four-roll calendering is used to determine the thickness (error ±0.2mm).

Composite process : The color film (printing accuracy 1200dpi) and the wear-resistant layer (0.3mm) are hot-pressed and the laminating pressure is ≥5MPa.

Post-processing technologyTempering : 80-120℃ hot water tempering to eliminate internal stress, shrinkage rate ≤0.01%.

Surface treatment : Diamond frosted surface and lychee grain antique treatment to improve anti-slip properties.

Quality Control

Physical Testing:Abrasion resistance revolutions ≥8000 revolutions (GB/T 18102), noise test ≤32dB (EN 14041).

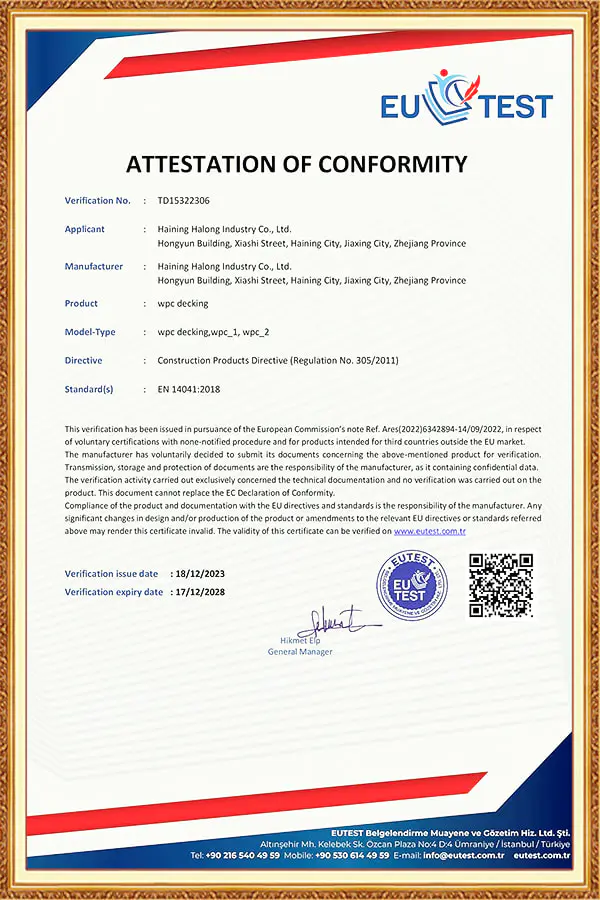

Environmental certification : Passed CARB certification, FLOORSCORE certification, CE certification (EU).

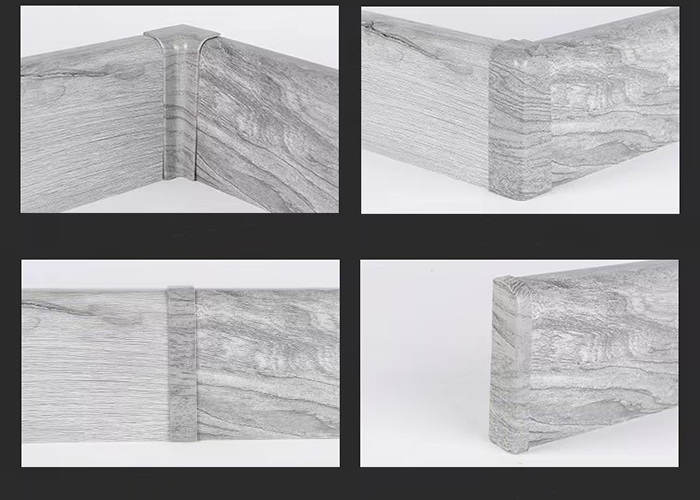

Locking technology

Mortise and tenon structure :Male tenon height 1.5mm, female groove depth 1.6mm, bite strength ≥150N/mm².

Elastic lock: Built-in EPDM buffer layer, suitable for ground flatness error ≤3mm/2m.

Established in 2005, our factory started with producing PVC Ceiling and Wall Panels, and has grown to be a professional China PVC ceiling panels manufacturer and a wholesale PVC panels factory, committed to providing our customers with high-quality products and services. After 20 years of development, we now own 5 large factories: Haining Halong PVC Ceiling Factory, Haining Longtime Film Factory, Guangxi PVC Wall Panel Factory, Indonesia PVC Wall Panel Factory, and Vietnam PVC Wall Panel Factory.

Our main products include: PVC Ceiling Panels, PVC Wall Panels, WPC Wall Panels, Hot Stamping Foil, PVC Lamination Film, SPC Flooring, WPC Decking, and other related products. Our annual sales can reach up to 35 million USD.

Industry Background and Application Importance In modern commercial and residential interior construction, wall panel systems are increasingly evaluated not only on aesthetics, but...

View MoreIndustry Background and Application Importance Decorative surface materials play a critical role in modern construction, interior systems, and modular building solutions. Tradition...

View MoreIndustry Background and Application Significance In modern construction, the choice of materials significantly impacts the durability, performance, and maintenance costs of a build...

View MoreRemoving PVC Self-Adhesive Wall Sticker from glass surfaces can be a challenging task if not approached correctly. The process requires understanding the adhesive properties, the t...

View More